Installation and Operation of Diaphragm Pump

2025.10.03

2025.10.03

Industry News

Industry News

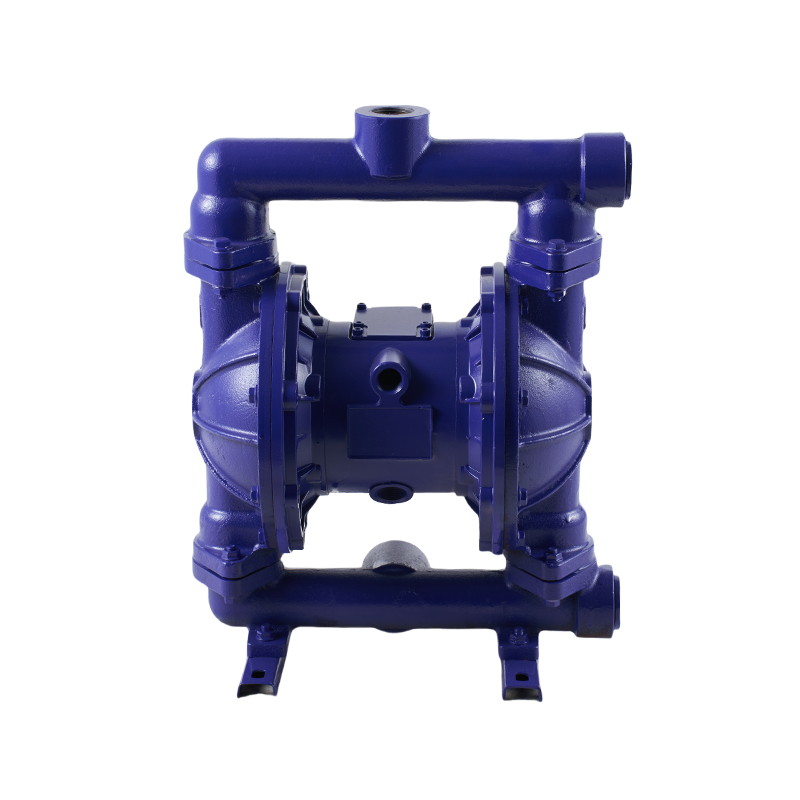

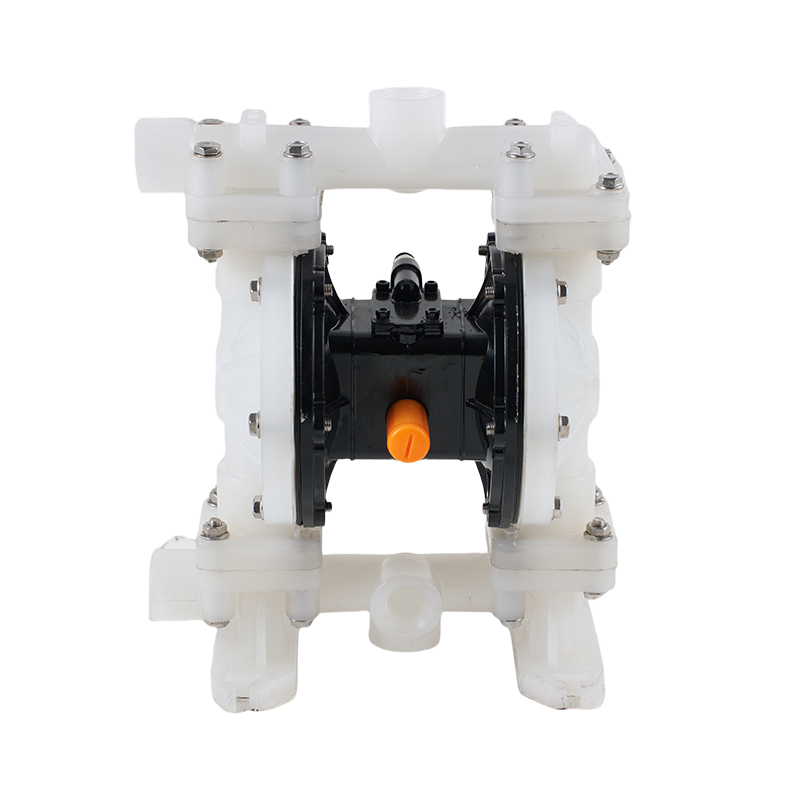

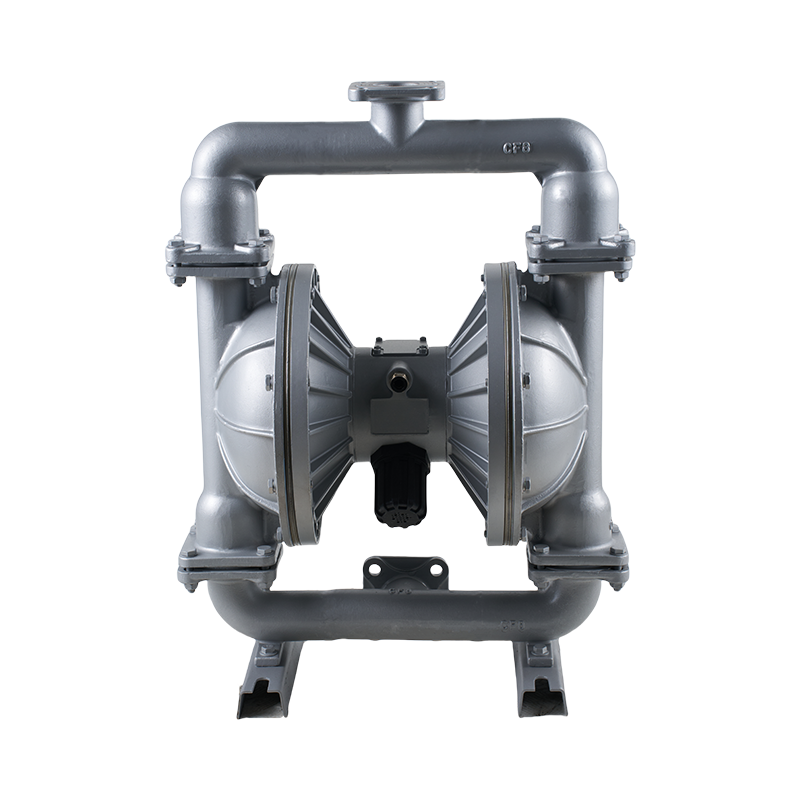

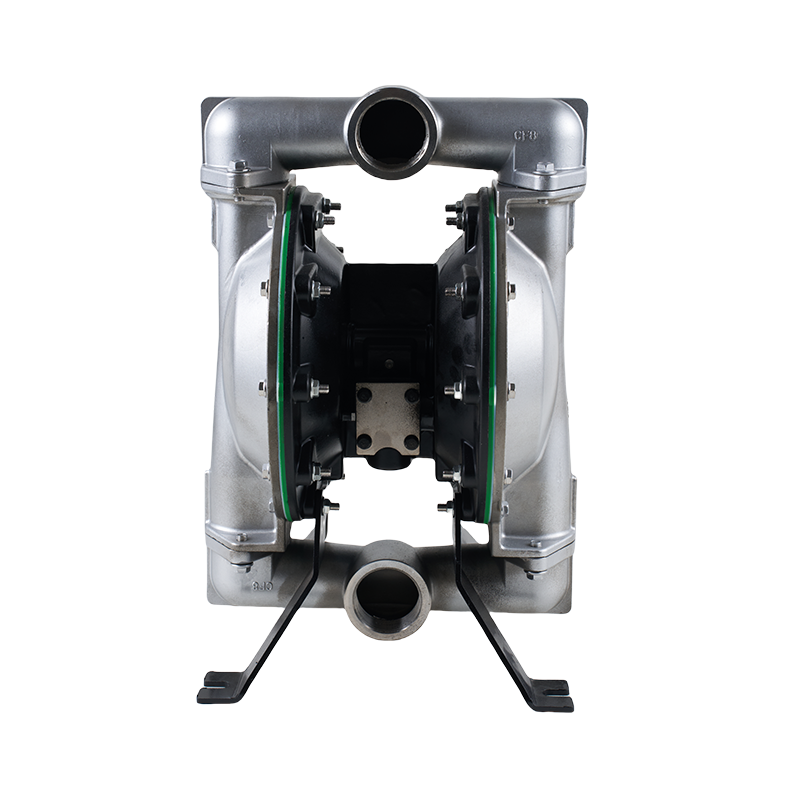

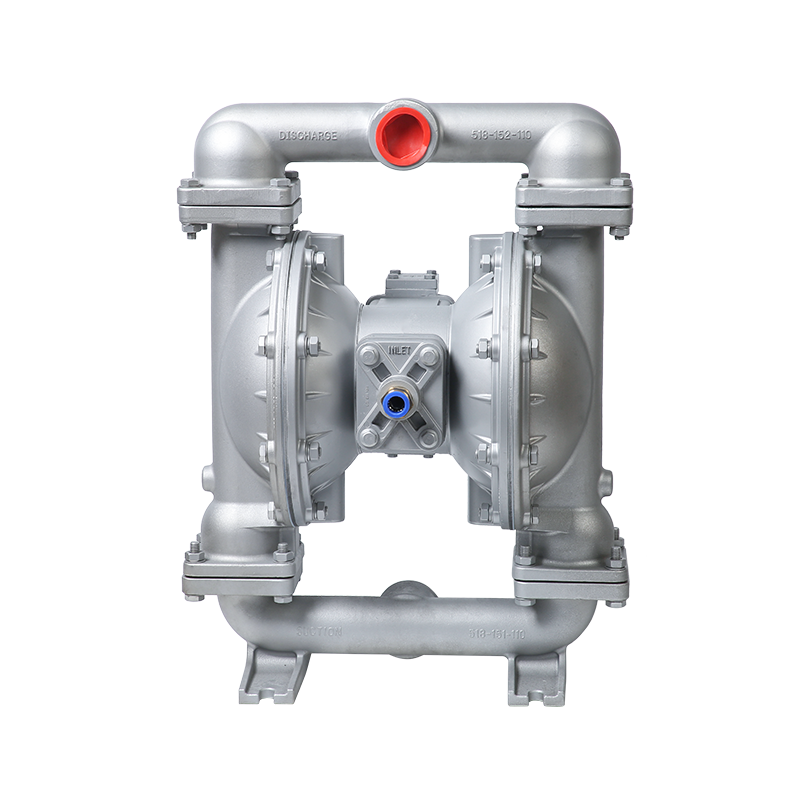

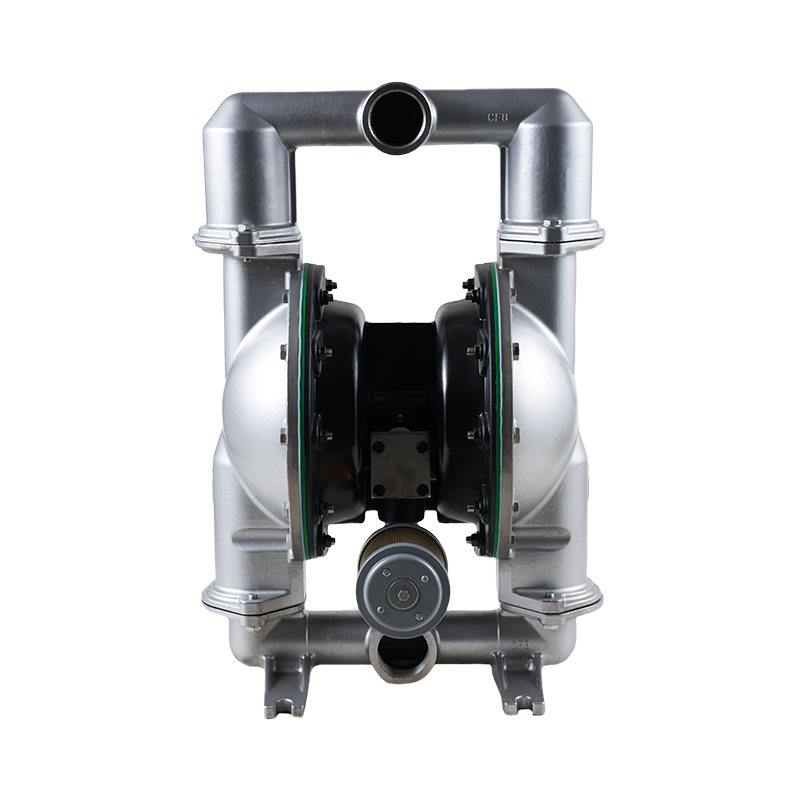

Diaphragm Pump has become an essential choice in many industries due to its versatility, ability to handle viscous or corrosive fluids, and simple maintenance requirements. While its benefits are clear, proper installation, operation, and troubleshooting are crucial to ensure long-term performance.

Can Diaphragm Pumps Run Dry Without Damage?

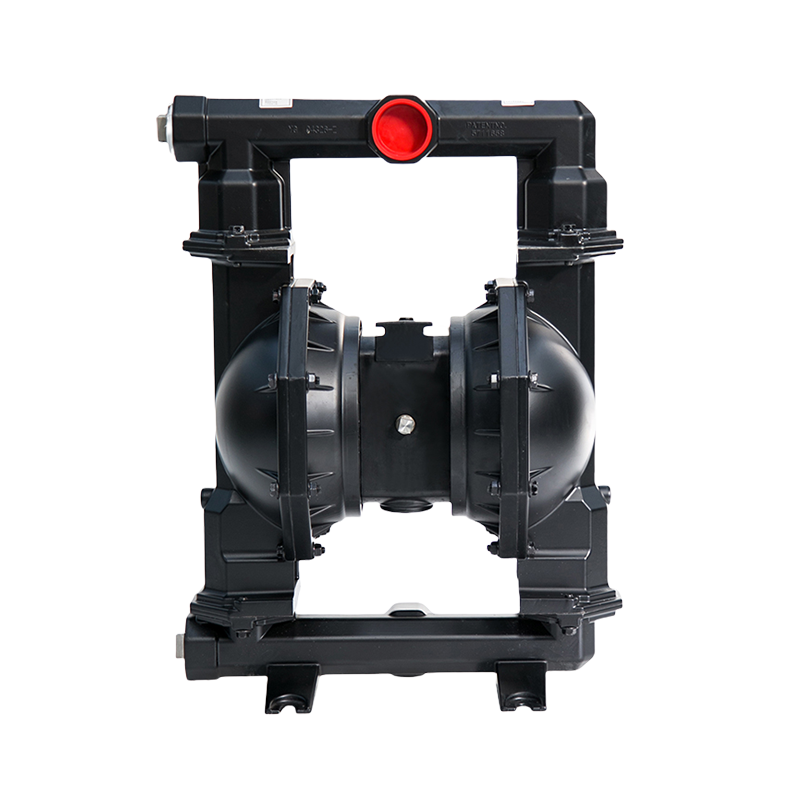

One of the common concerns for users is whether a diaphragm pump can operate without liquid inside the pump chamber. The answer largely depends on the type and construction of the diaphragm pump. Some air-operated diaphragm pumps and certain mechanically driven models are designed to tolerate short periods of dry running. However, running a diaphragm pump dry for extended periods can increase wear on the diaphragm, valves, and seals, potentially reducing the lifespan of the pump. To avoid damage, it is recommended to ensure the pump is primed and filled with liquid before starting. Some modern diaphragm pumps come with dry-run protection or monitoring systems to prevent accidental operation without fluid. Understanding the specific model and manufacturer recommendations is essential for safe operation.

What is the Correct Way to Install a Diaphragm Pump?

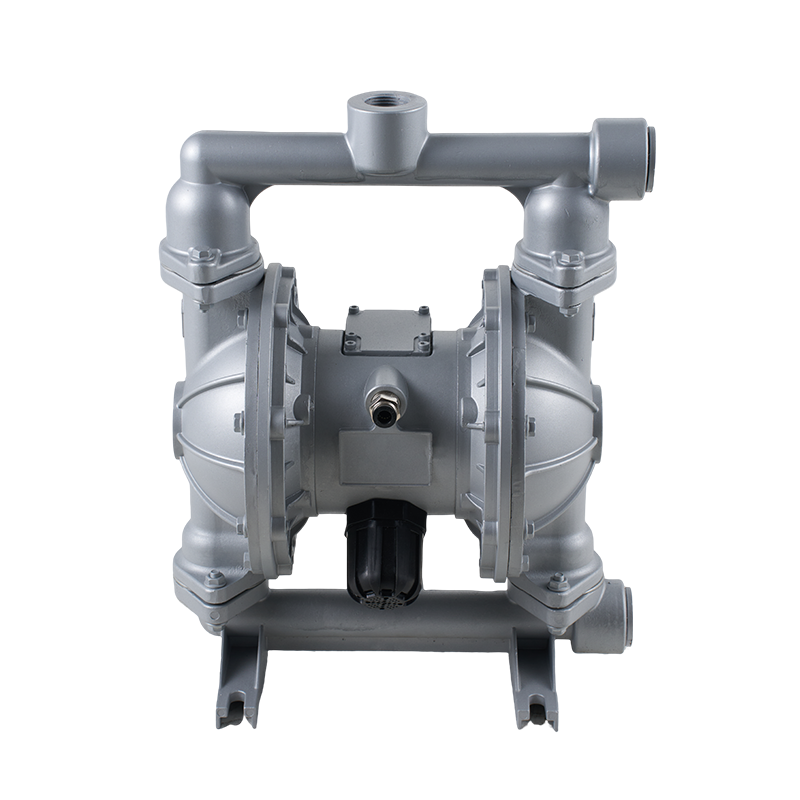

Proper installation is critical for performance and long-term reliability of a diaphragm pump. First, the pump should be mounted on a stable, level surface to prevent vibrations and misalignment. Secure mounting helps avoid leaks and mechanical stress on the pump components.

Next, attention should be given to the suction and discharge lines. The suction line should be as short and straight as possible, with minimal bends, to reduce resistance and improve priming. Installing a foot valve at the suction inlet can prevent backflow and maintain prime. The discharge line should also be adequately supported and sized according to the pump specifications.

Additionally, diaphragm pumps require correct orientation. Many pumps are designed for horizontal mounting, but some models allow vertical installation. Following the manufacturer’s guidelines ensures proper fluid flow and minimizes stress on internal parts. For air-operated diaphragm pumps, it is also important to use a clean, regulated air supply with appropriate pressure to prevent overloading and premature wear.

How Do You Troubleshoot a Diaphragm Pump That Is Not Pumping Correctly?

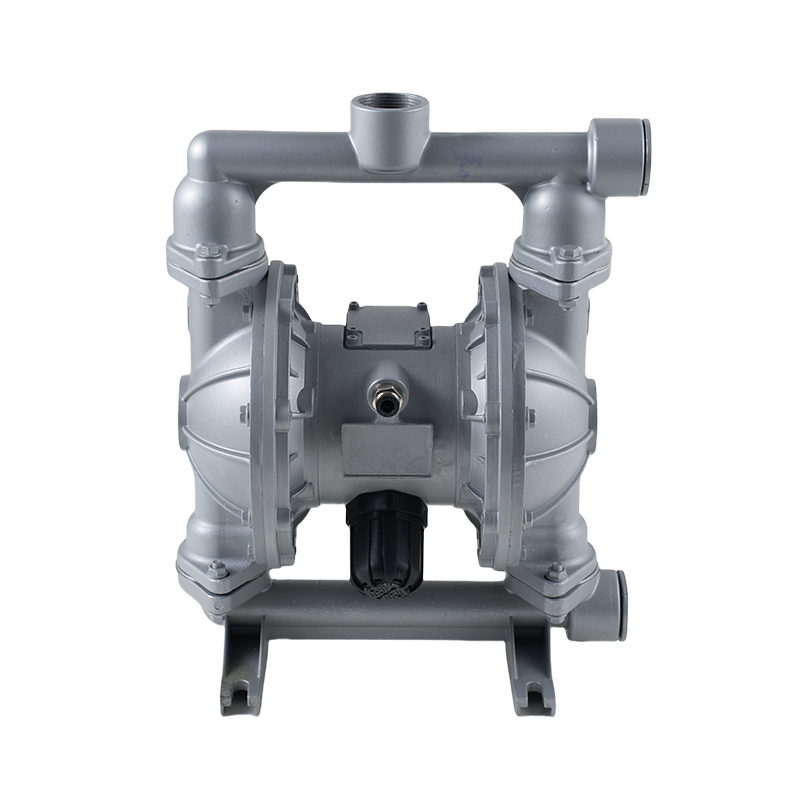

Even with proper installation and operation, issues may arise with diaphragm pumps. Common problems include reduced flow, irregular pulsation, or no discharge at all. Troubleshooting typically starts by checking the basic components. First, inspect the suction line for blockages or leaks that could prevent proper priming. Next, check the discharge line for restrictions or closed valves.

If lines are clear, the diaphragm and valves should be examined. Worn or damaged diaphragms and faulty check valves are frequent causes of pumping issues. Replacing these parts as needed usually restores normal operation. For air-operated pumps, verify that the air supply is adequate, clean, and properly regulated, as insufficient or contaminated air can affect pump performance. Regular maintenance and inspection can prevent many common problems and extend the pump’s service life.

Diaphragm pumps are reliable and versatile tools, but proper attention to dry running, installation, and troubleshooting is essential. While some models can tolerate brief dry operation, it is to prime the pump before use. Correct installation involves stable mounting, properly sized and supported suction and discharge lines, and adherence to manufacturer guidelines. Troubleshooting a diaphragm pump that is not pumping correctly involves inspecting lines, valves, diaphragms, and air supply. By understanding and addressing these key aspects, users can ensure that their diaphragm pump operates efficiently, safely, and with a long service life.

English

English русский

русский Español

Español عربى

عربى