Handling Abrasive Fluids With Durable Diaphragm Pump Technology

2025.10.10

2025.10.10

Industry News

Industry News

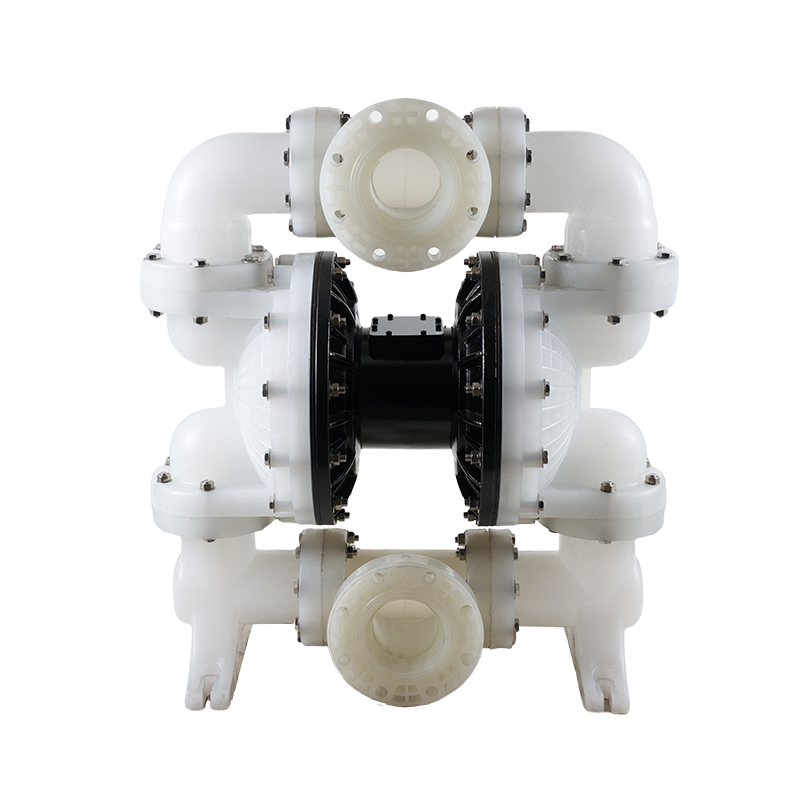

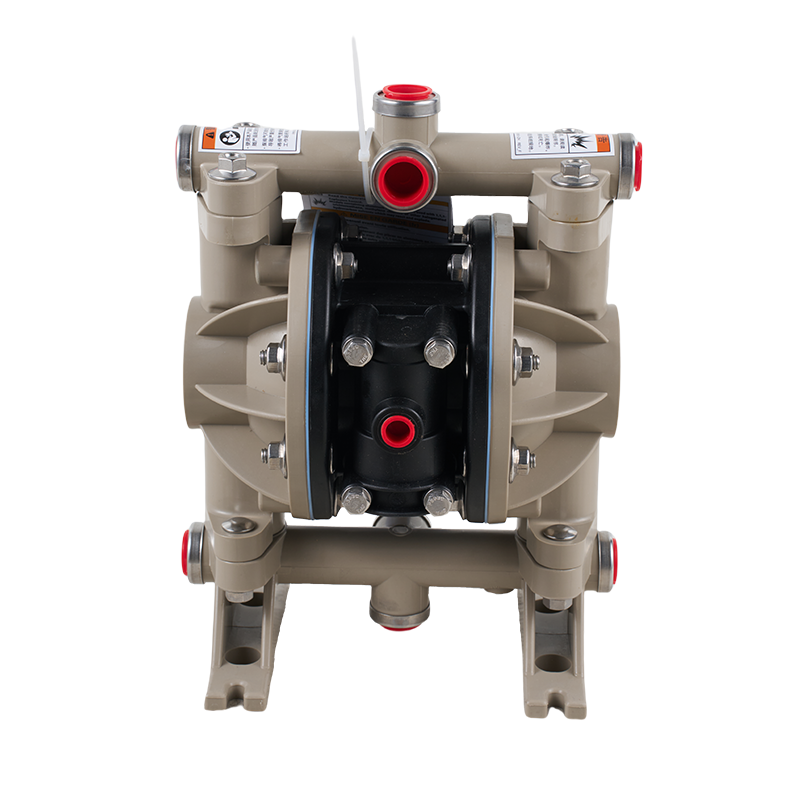

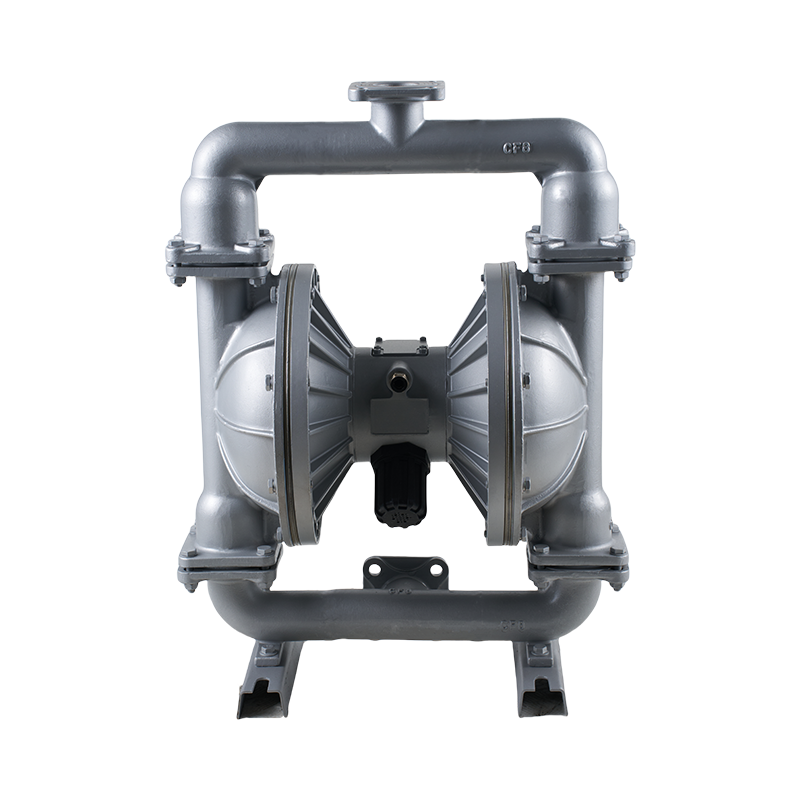

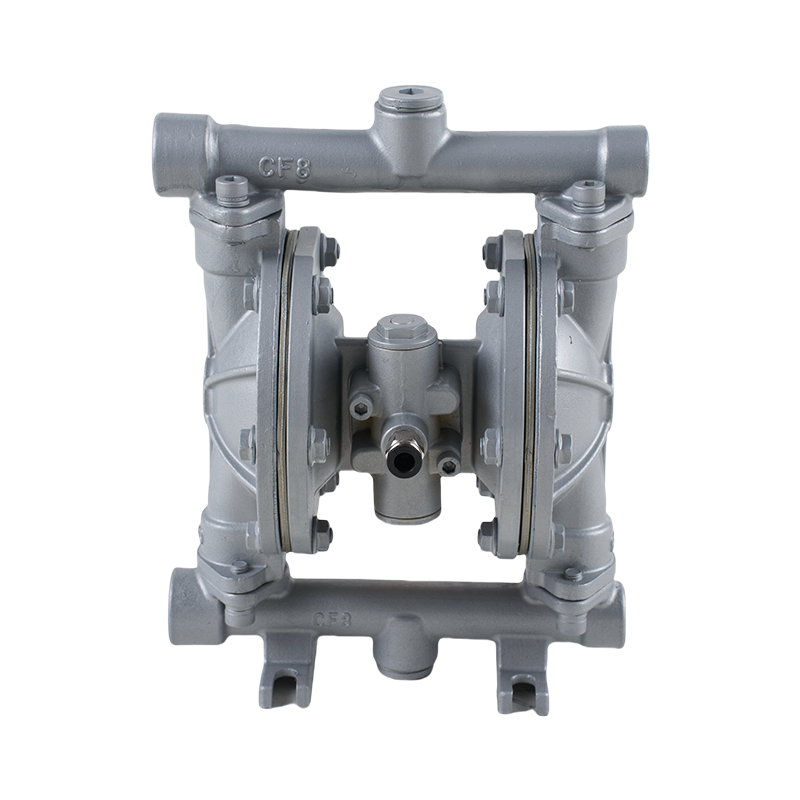

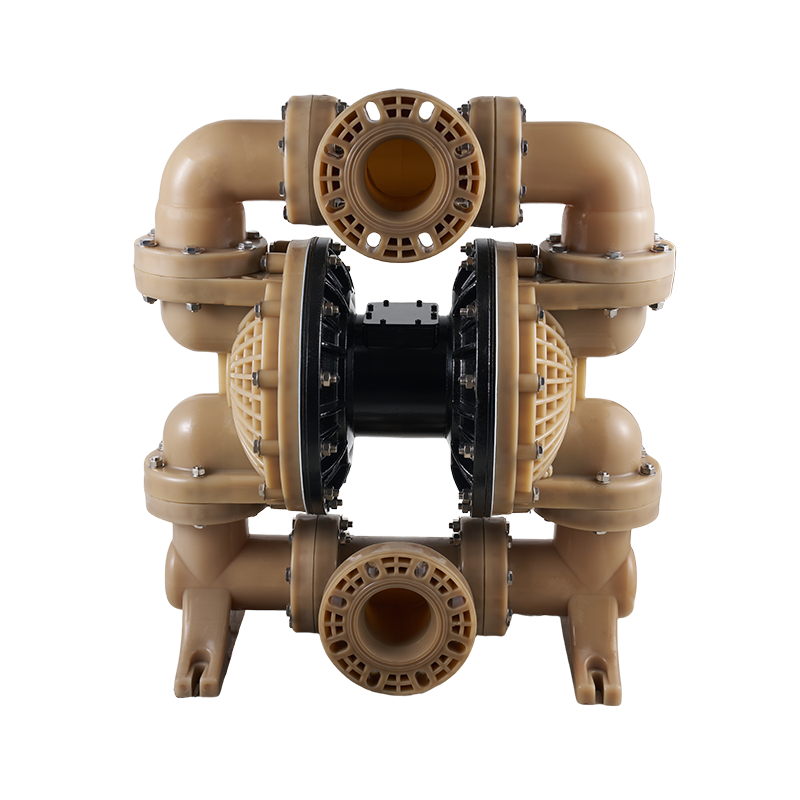

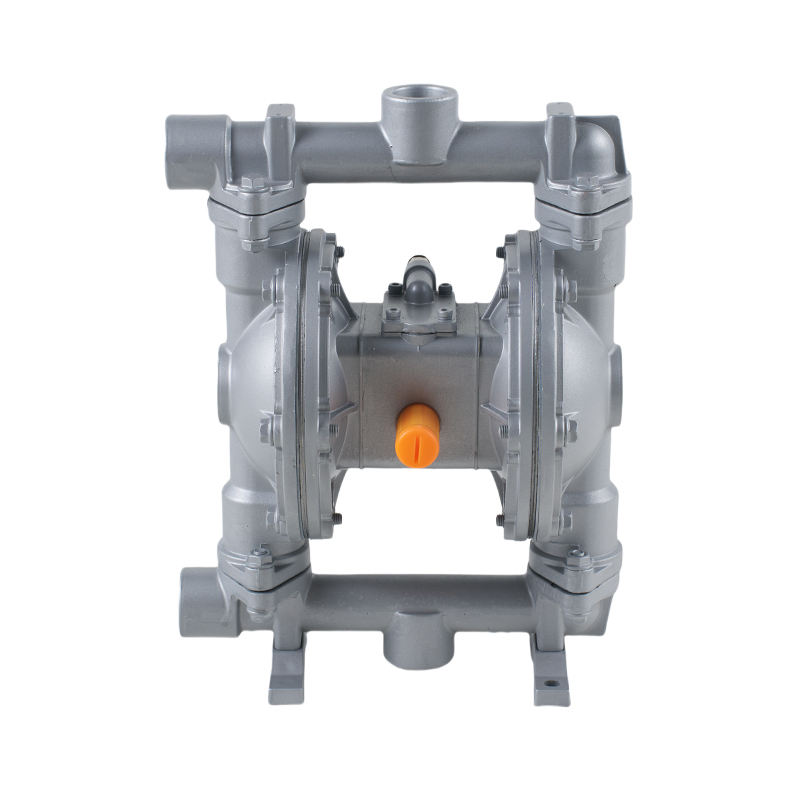

In many industrial settings, from mining and ceramics manufacturing to wastewater treatment and chemical processing, the challenge of moving abrasive fluids is a constant operational concern. These fluids, laden with solid particles, can rapidly degrade equipment, causing frequent downtime, high maintenance costs, and lost productivity. In this demanding context, the technology behind the Diaphragm Pump becomes critically important. Specifically, the expertise of a Chinese Diaphragm Pump Supplier Manufacturer has become a focal point for industries seeking a balance of durability, performance, and value.

The resilience of a Diaphragm Pump against abrasive fluids is rooted in its fundamental design principle and the materials used in its construction. Unlike centrifugal pumps that rely on high impellers, a Diaphragm Pump operates on a positive displacement mechanism. It uses a reciprocating diaphragm to move fluid, creating a suction and discharge action with no internal high-rotating components in direct contact with the slurry. This design significantly reduces the wear-and-tear that defines the failure of other pump types in abrasive services.

Material Science: The Line of Defense

The wetted parts of the pump—the chamber, the valves, and the balls—are the components that directly engage with the abrasive fluid. A reputable Chinese Diaphragm Pump Supplier Manufacturer will offer these components in a range of hardened materials to match the specific abrasiveness of the application. While polypropylene is fine for chemical corrosion, materials like hardened stainless steel, cast iron, or even engineered ceramics may be specified for their exceptional resistance to mechanical wear. The ability to select a Diaphragm Pump configured with the appropriate wear-resistant materials is a direct contributor to its extended service life. China Diaphragm Pump Supplier Manufacturer's expertise lies in guiding customers to select the appropriate material combination based on their specific fluid characteristics.

Optimized Hydraulics and Flow Paths

Beyond material hardness, the hydraulic design plays a crucial role. A well-designed Diaphragm Pump from an experienced Chinese Diaphragm Pump Supplier Manufacturer will feature smooth, streamlined flow paths within the pump chamber. The goal is to identify turbulence and areas where particles can accumulate or cause erosive wear. Furthermore, the air distribution system that drives the diaphragm's reciprocation is calibrated for a smooth, controlled stroke. A jerky or overly aggressive action can create water hammer effects that stress the pump and the piping system, potentially accelerating wear. The consistent, reliable operation of a Diaphragm Pump is a testament to the refined engineering behind it.

The Advantage of Dry-Running and Self-Priming Capabilities

A common failure point for pumps handling abrasive fluids is run-dry situations, which can occur due to an unexpected drop in fluid level. The Diaphragm Pump is inherently capable of running dry for extended periods without damage. This characteristic is a significant safety net in abrasive applications, preventing catastrophic failure during temporary operational hiccups. Additionally, the strong self-priming ability of the Diaphragm Pump means that it can evacuate air and start moving fluid effectively, which is often necessary in sump or transfer applications where the fluid level varies.

Handling abrasive fluids is a task that demands robust and intelligent engineering. The Diaphragm Pump, with its wear-resistant material options, low-shear pumping action, and forgiving operational characteristics, presents a compelling solution. The value offered by a knowledgeable Chinese Diaphragm Pump Supplier Manufacturer is the assurance that the pump is not just a generic tool, but a specifically configured asset built to withstand challenging conditions, thereby protecting your operations from the high costs of downtime and frequent replacements.

English

English русский

русский Español

Español عربى

عربى