Installation and Use of Double Diaphragm Pump

2025.09.25

2025.09.25

Industry News

Industry News

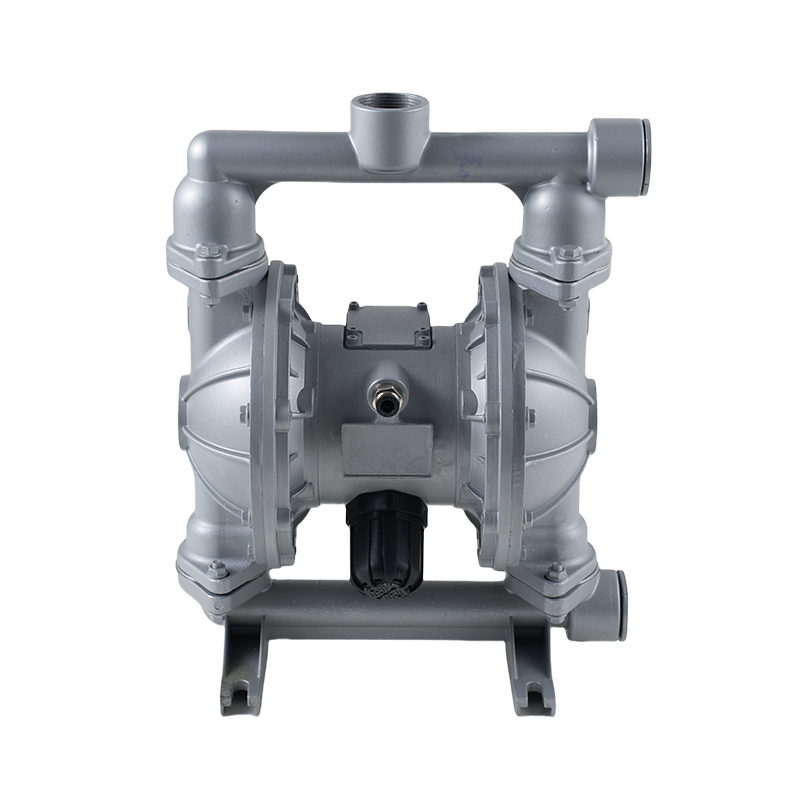

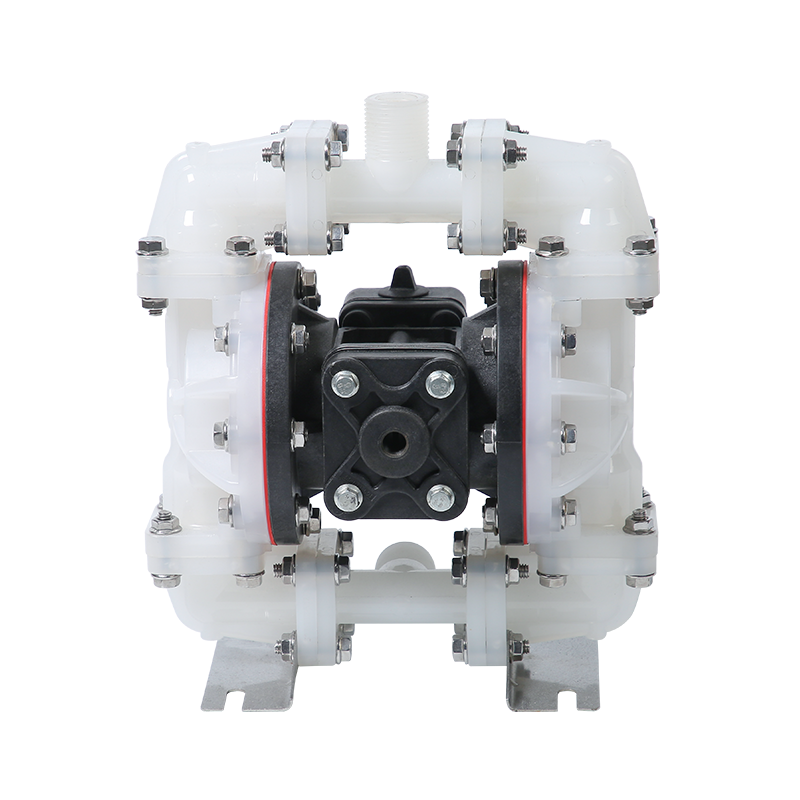

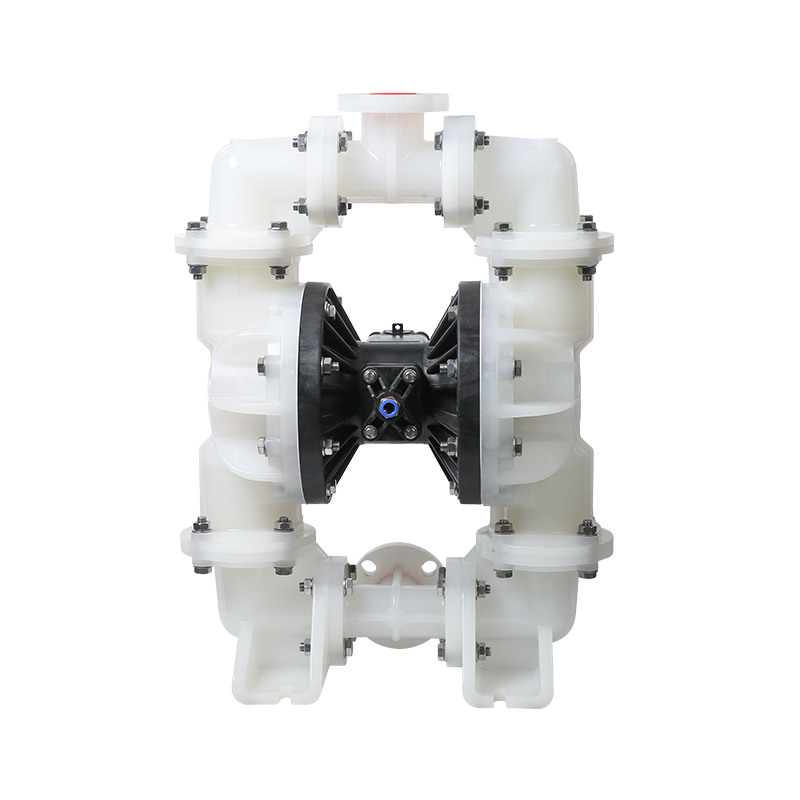

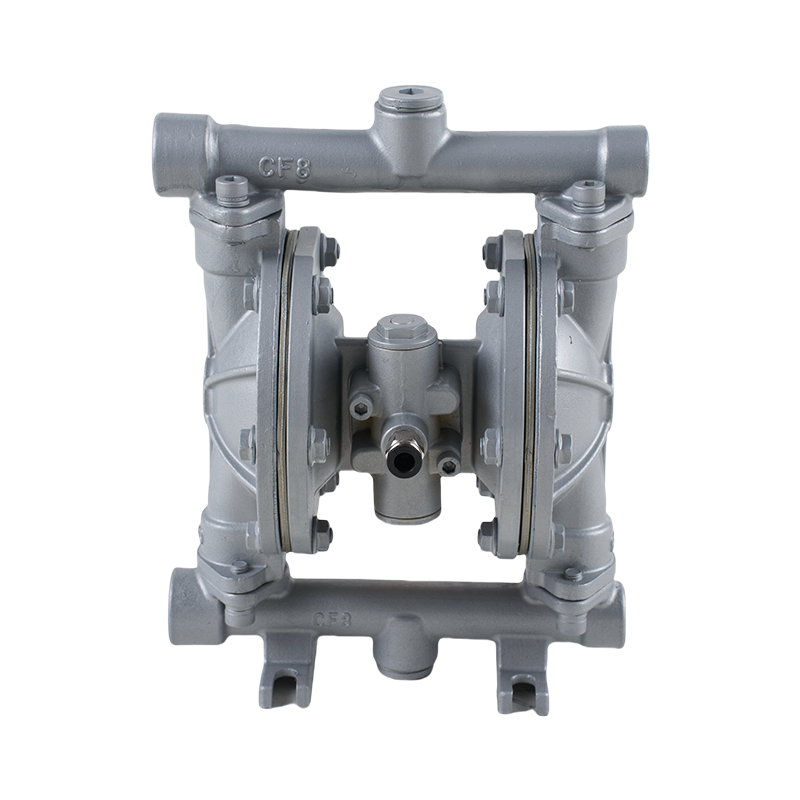

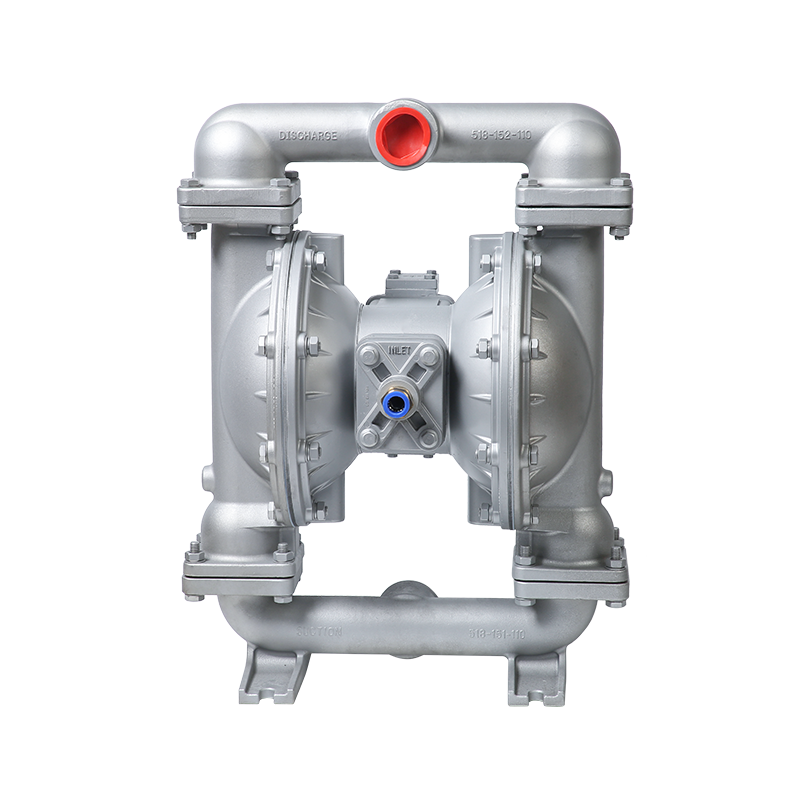

The Double Diaphragm Pump is widely recognized for its versatility, reliability, and ability to handle a variety of fluids, including abrasive and chemically aggressive liquids. For users and maintenance personnel, understanding proper installation, routine maintenance, and safety considerations is crucial. This article addresses these aspects in detail by answering common questions.

How do you install a double diaphragm pump?

Installing a Double Diaphragm Pump requires careful attention to ensure performance and longevity. First, select a level and stable surface for mounting, as uneven placement can cause vibration or misalignment. Air-operated double diaphragm pumps typically require connection to a clean, dry air supply with regulated pressure, while electric-driven versions need a secure electrical connection following manufacturer guidelines.

Next, ensure that the inlet and outlet piping is properly aligned to avoid excessive strain on the pump body. It is important to install valves, such as check valves or strainers, to protect the pump from debris and to maintain smooth flow. Properly securing hoses or pipes and avoiding sharp bends will help prevent backflow, cavitation, or premature wear. Finally, perform a test run after installation to check for leaks, proper flow, and air or electrical supply stability.

What kind of maintenance does it require?

Routine maintenance is essential for a Double Diaphragm Pump to function efficiently and extend its lifespan. Regular inspection of diaphragms, valves, and seals helps identify early signs of wear or damage. Diaphragms and valves should be replaced according to the manufacturer’s recommendations, or sooner if signs of cracking, deformation, or leakage appear.

Lubrication requirements vary depending on the pump type. Air-operated pumps often rely on the air supply’s moisture and filtered oil, while electric versions may require occasional bearing lubrication. It is also important to clean the pump regularly, especially when handling viscous or particulate-laden fluids. Ensuring that inlet filters and strainers are free from blockage will maintain proper flow and prevent pressure loss. Following a structured maintenance schedule will reduce downtime and improve overall reliability.

Can it be used in hazardous or explosive environments?

The Double Diaphragm Pump is often suitable for use in hazardous or explosive environments, particularly air-operated versions. Because these pumps do not require electrical components for operation, they are less likely to produce sparks that could ignite flammable substances. This makes them ideal for chemical processing, paint transfer, and fuel handling applications where safety is critical.

For electric-driven double diaphragm pumps, proper certification and compliance with safety standards, such as ATEX or IECEx, are necessary before installation in hazardous areas. Additional measures, including grounding, explosion-proof housings, and safe electrical connections, are essential to ensure safe operation in environments containing flammable gases, vapors, or dust.

Proper installation and use of a Double Diaphragm Pump are key to achieving reliable performance and safety. Installation involves selecting a stable surface, aligning piping correctly, and performing a test run. Maintenance includes regular inspection, diaphragm replacement, cleaning, and proper lubrication. For hazardous or explosive environments, air-operated pumps provide inherent safety advantages, while electric pumps require certification and additional precautions.

Understanding these aspects allows users to operate a Double Diaphragm Pump efficiently, minimize downtime, and maintain safe working conditions across a variety of industrial applications. With proper care, this versatile pump offers long-lasting performance and reliable fluid transfer for demanding operations.

English

English русский

русский Español

Español عربى

عربى