Why Your Industry Needs the Advanced Pneumatic Double Air Diaphragm Pump?

2025.08.17

2025.08.17

Industry News

Industry News

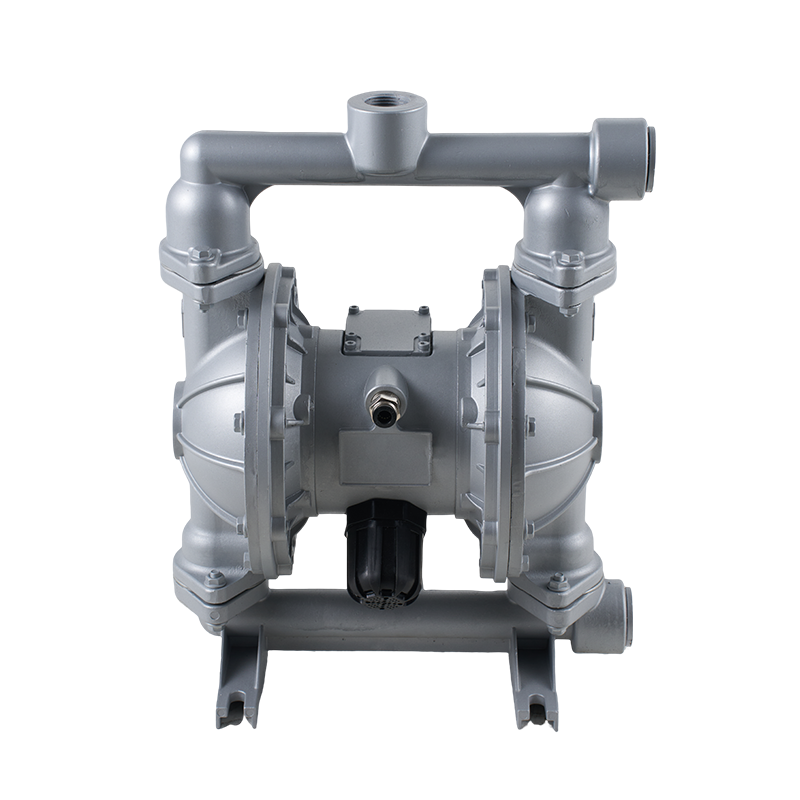

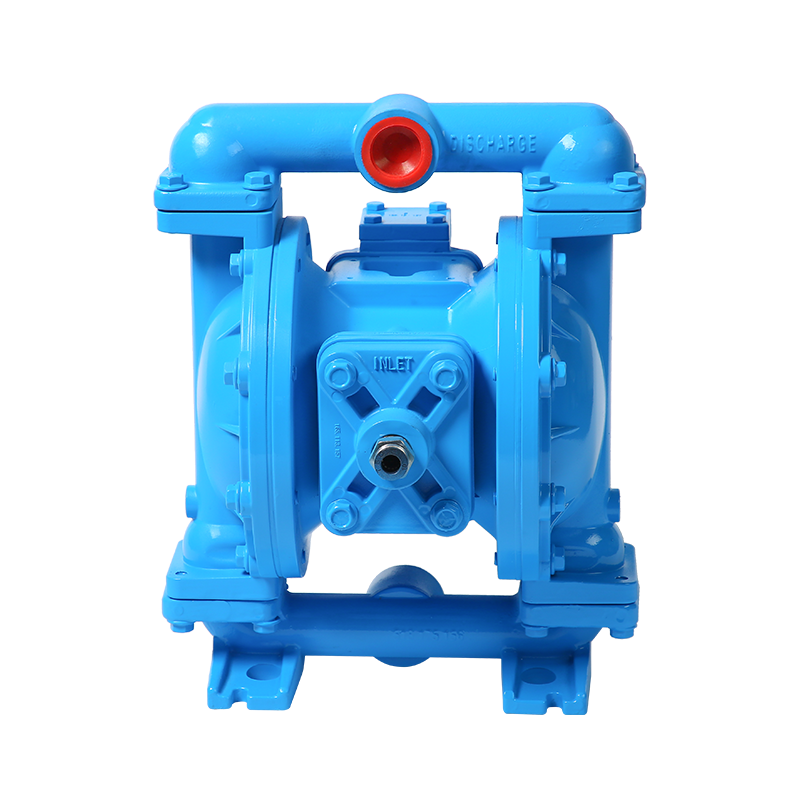

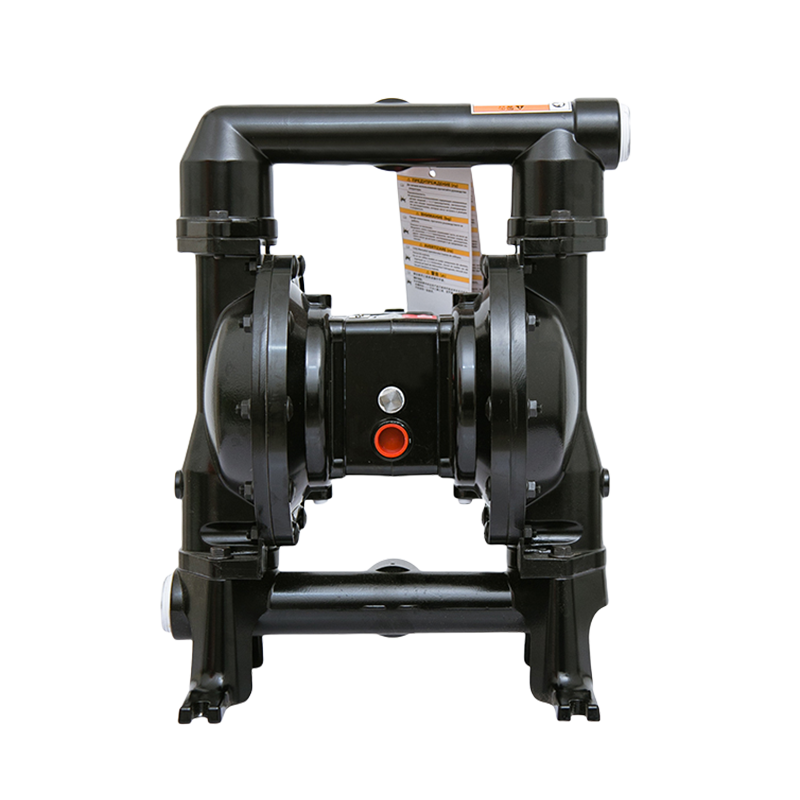

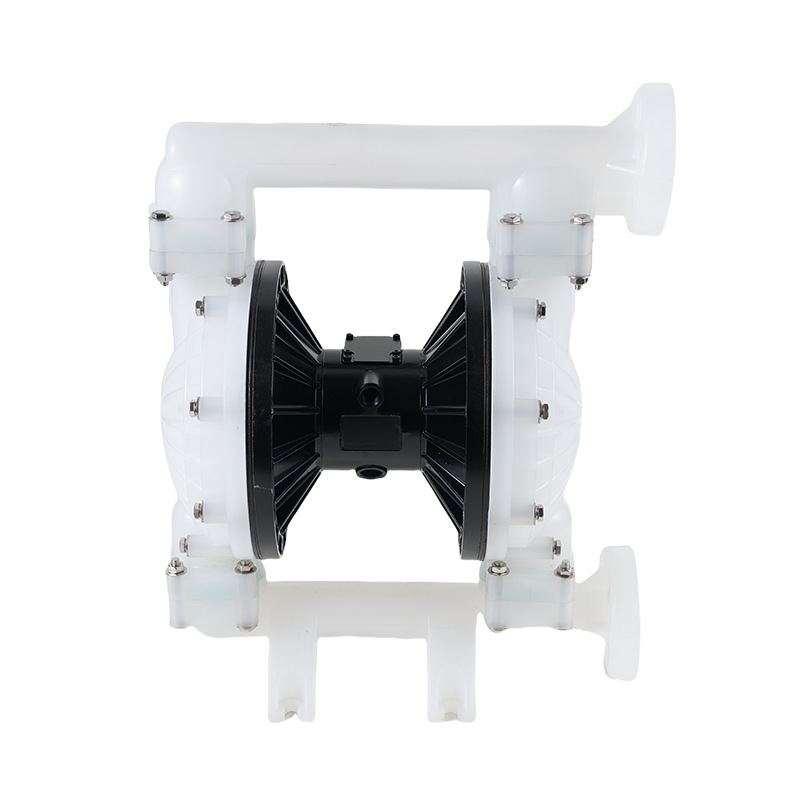

One piece of equipment that has been quietly revolutionizing various sectors is the Pneumatic Double Air Diaphragm Pump. This advanced technology is not just a tool; it's a game-changer for industries ranging from manufacturing and chemical processing to mining and wastewater management.

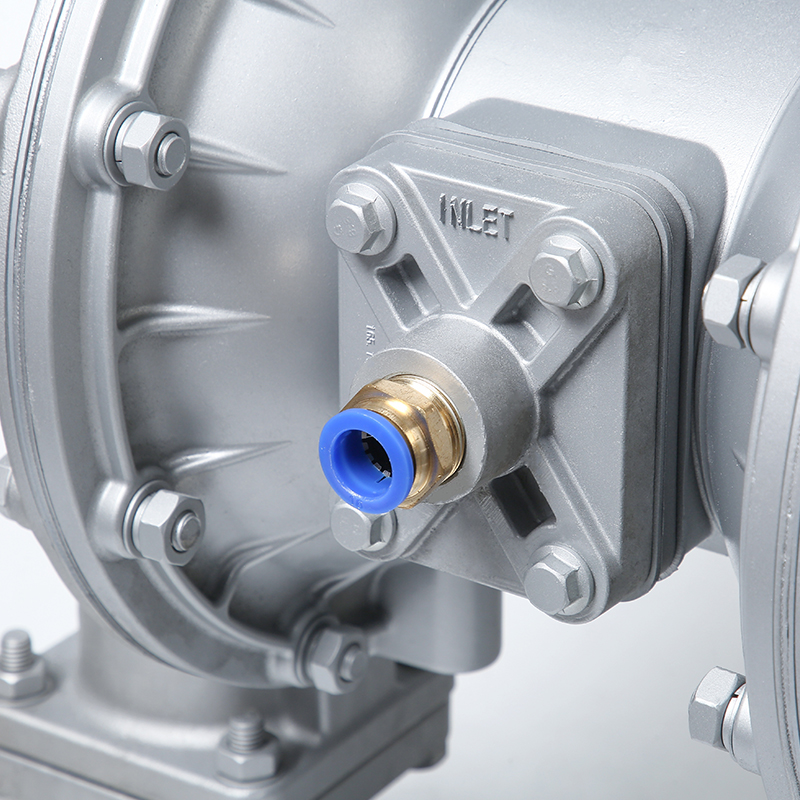

To begin with, the Pneumatic Double Air Diaphragm Pump is a marvel of engineering. Unlike traditional pumps that rely on complex electrical systems, this pump operates on compressed air. The term Pneumatic is derived from the Greek word for wind or breath, and it aptly encapsulates the simplicity and power of this technology. By using air pressure to drive the pumping mechanism, these devices eliminate the risk of electrical hazards, making them ideal for use in environments where flammable liquids or gases are present. This is particularly crucial in the chemical industry, where safety is paramount.

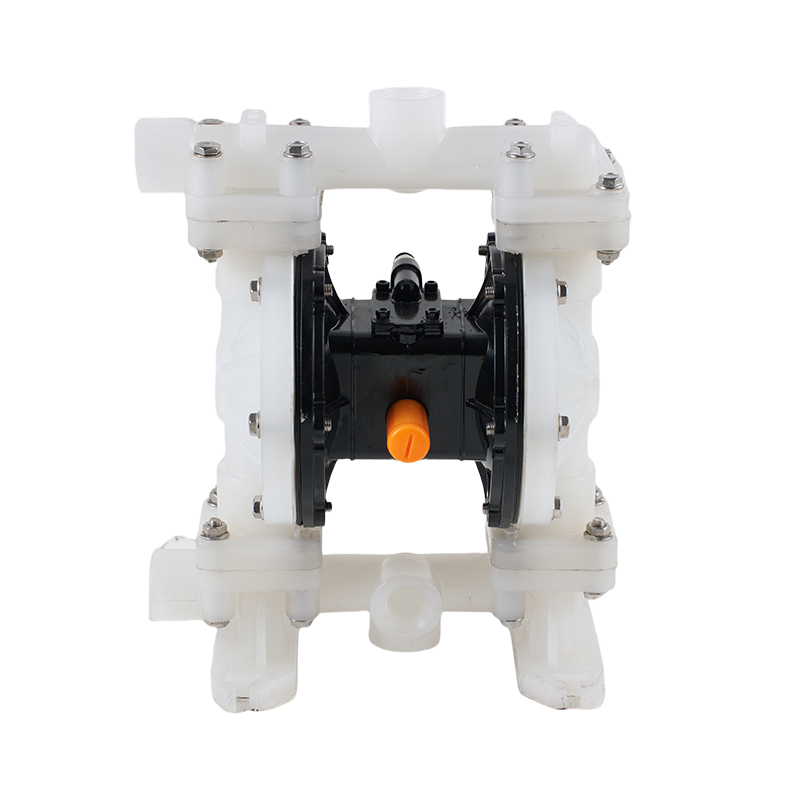

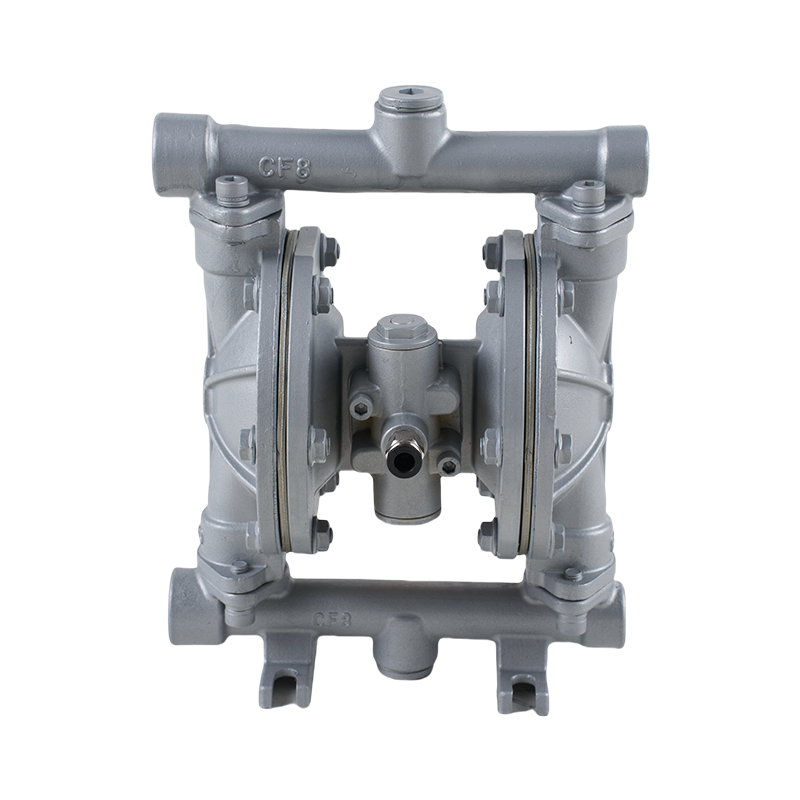

The Double Air Diaphragm design is another key feature that sets this pump apart. It consists of two flexible diaphragms that move in tandem, creating a continuous flow of fluid. This dual-diaphragm system not only increases the efficiency of the pump but also ensures a smooth and consistent flow rate. Whether you're transferring corrosive chemicals, viscous slurries, or even abrasive materials, the Pneumatic Double Air Diaphragm Pump can handle it all. Its ability to self-prime and run dry without damage makes it incredibly versatile and reliable.

One of the significant advantages of the Pneumatic Double Air Diaphragm Pump is its maintenance-friendly design. Traditional pumps often require frequent servicing and part replacements due to their complex internal mechanisms. In contrast, the Pneumatic Double Air Diaphragm Pump has fewer moving parts, which means fewer points of failure. This translates to lower maintenance costs and less downtime, which is a major benefit for any industry. Imagine a manufacturing plant that can operate continuously without worrying about pump failures. The impact on productivity and profitability is substantial.

Moreover, the Pneumatic Double Air Diaphragm Pump is incredibly energy efficient. Since it runs on compressed air, it uses less energy compared to electric pumps. In an era where energy conservation and sustainability are global priorities, this feature cannot be overstated. Industries can significantly reduce their carbon footprint by adopting this advanced technology. For example, in the wastewater treatment sector, where pumps are used extensively to transfer water and sludge, the energy savings from using Pneumatic Double Air Diaphragm Pumps can be substantial.

Another important aspect is the material used in the construction of these pumps. Many Pneumatic Double Air Diaphragm Pumps are made from high-quality aluminum. This material is not only lightweight but also highly durable and resistant to corrosion. The Aluminium Diaphragm Pump is particularly well-suited for applications where weight is a concern, such as in mobile equipment or offshore platforms. Its corrosion-resistant properties make it ideal for handling a wide range of fluids, including those with high acidity or alkalinity.

The flexibility of the Pneumatic Double Air Diaphragm Pump is another reason why it is so valuable to industries. It can be easily adjusted to different flow rates and pressures, making it suitable for a variety of tasks. Whether you need to transfer a small amount of fluid or a large volume, this pump can be configured to meet your specific needs. This adaptability is particularly useful in the food and beverage industry, where precise control over fluid transfer is essential to maintain product quality and consistency.

In addition to its technical advantages, the Pneumatic Double Air Diaphragm Pump also offers significant cost savings. While the initial investment may be higher compared to some traditional pumps, the long-term benefits far outweigh the costs. The reduced maintenance requirements, lower energy consumption, and increased reliability all contribute to a lower total cost of ownership. For industries that rely heavily on pumping operations, this can translate to substantial savings over time.

The Pneumatic Double Air Diaphragm Pump is a technological advancement that every industry should consider adopting. Its safety features, efficiency, durability, and versatility make it an invaluable asset in modern industrial operations. From the chemical plants that require precise and safe fluid transfer to the mining operations that need rugged and reliable equipment, the Pneumatic Double Air Diaphragm Pump stands out as a solution that meets and exceeds expectations. As industries continue to evolve and face new challenges, the Pneumatic Double Air Diaphragm Pump is poised to play a crucial role in driving progress and ensuring success.

English

English русский

русский Español

Español عربى

عربى