Sealless And Safe: The Operational Advantage Of A Diaphragm Pump

2025.10.17

2025.10.17

Industry News

Industry News

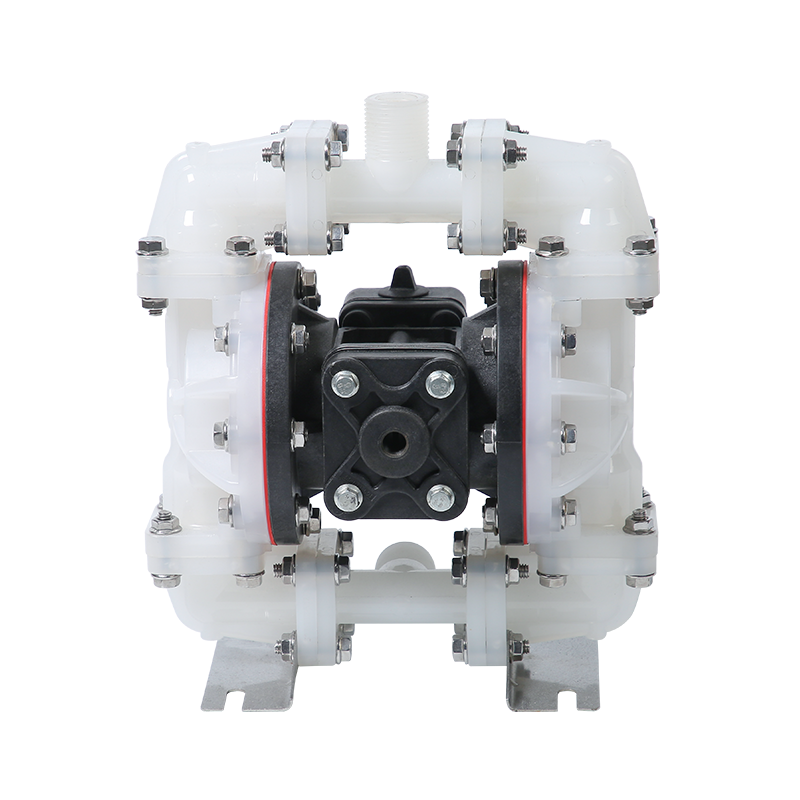

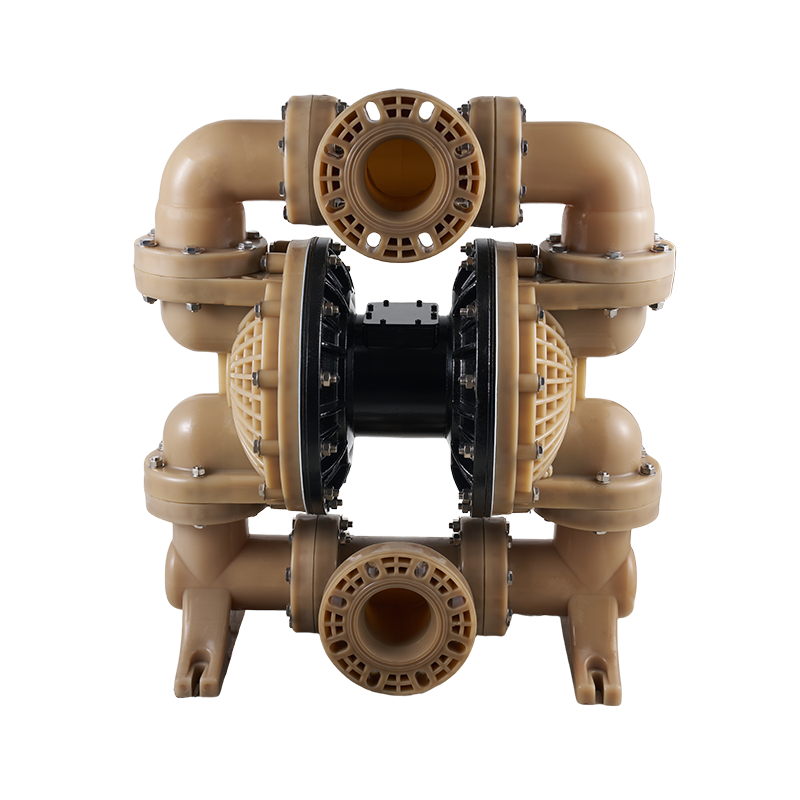

In industrial fluid handling, the priorities of safety, reliability, and environmental compliance are paramount. Operations managers and plant engineers are consistently faced with the challenge of selecting equipment that not only performs efficiently but also mitigates risk. A recurring point of failure in many pumping systems is the mechanical seal, a component notorious for leaks, maintenance demands, and potential safety hazards. It is in this context that the fundamental design of the Diaphragm Pump presents a significant operational advantage. But how does the absence of a seal translate into tangible benefits, and when does a standard pump fall short, making the case for a Customized Diaphragm Pump?

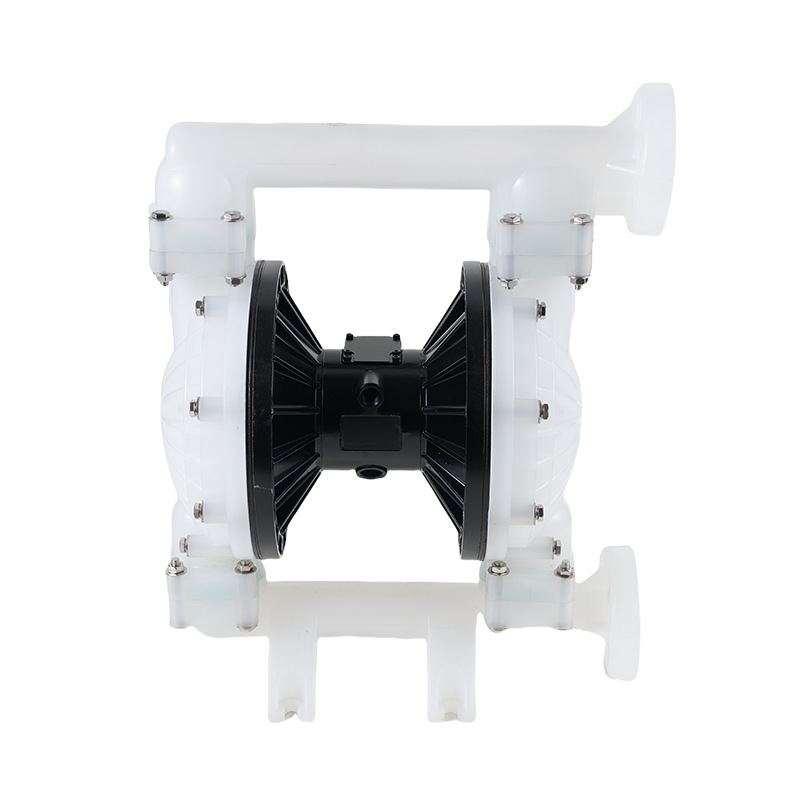

The core of this advantage lies in the sealless nature of the diaphragm pump's design. Unlike centrifugal or other rotary pumps that require a dynamic seal around a rotating shaft, a diaphragm pump isolates the fluid within a chamber created by the diaphragm and the pump housing. The driving force—whether compressed air or an electric motor—acts on the outside of the diaphragm, moving it reciprocally to displace the fluid. This physical barrier eliminates the pathway through which leaks commonly occur. This inherent safety feature is a primary reason why diaphragm pumps are specified for handling hazardous, toxic, or expensive fluids. However, to fully leverage this advantage for specific applications, the support of an experienced Customized Diaphragm Pump Manufacturer is often necessary.

Handling Difficult Fluids with Reliability

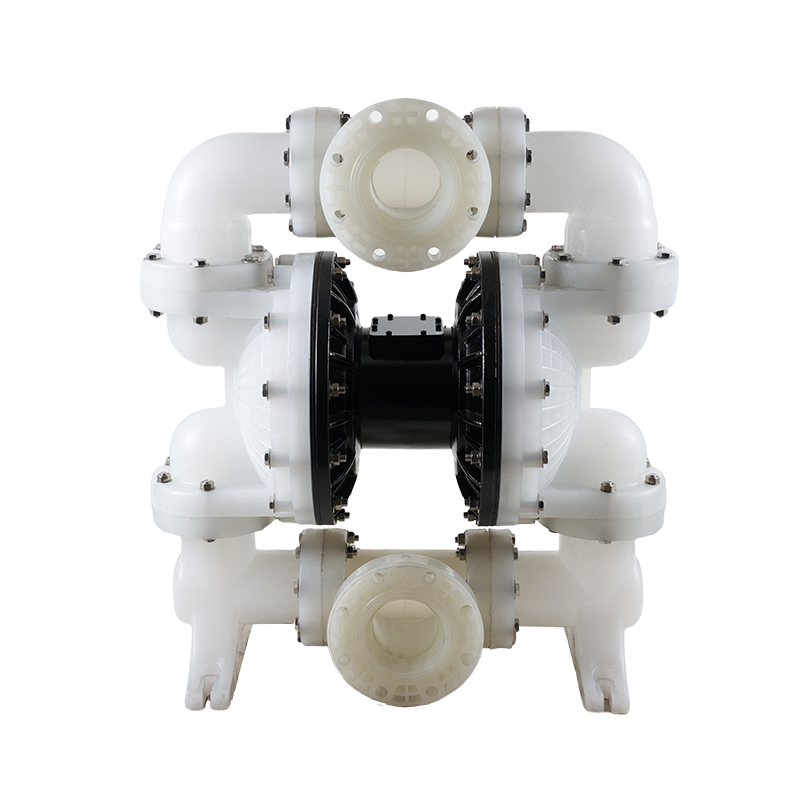

The safety advantage extends beyond just containing leaks. The gentle, low-shear pumping action of a diaphragm pump makes it suitable for shear-sensitive fluids like polymers, latex, or fluids containing fragile solids. Agitating these fluids with a high-impeller could damage the product. Furthermore, the pump's ability to run dry without damage provides an additional layer of operational safety, preventing a catastrophic failure should a feed line run empty. This combination of traits makes the diaphragm pump uniquely versatile. This is where a customized Diaphragm Pump Manufacturer provides value, perhaps by adjusting port sizes, valve configurations, or the stroke characteristics of the Customized Diaphragm Pump to efficient handling without clogging or fluid degradation.

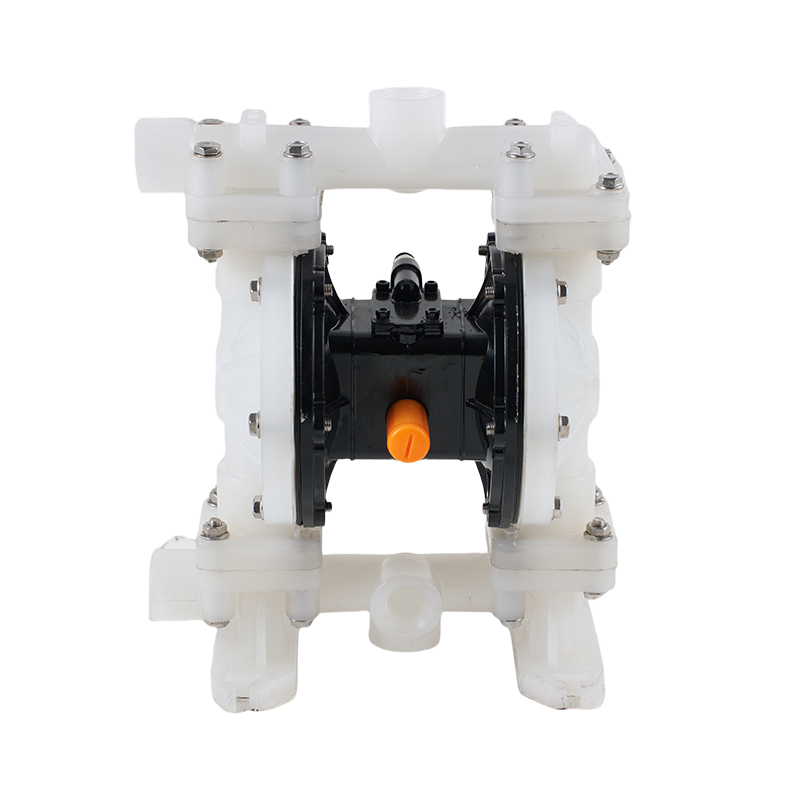

The Role of Customization in Safety

While all diaphragm pumps are sealless, not all are created equal for every application. A standard pump might be adequate for general service, but specialized conditions demand a tailored approach. Similarly, an application requiring a high degree of inertness might necessitate a pump with a PTFE diaphragm and lining, a specification easily handled by a competent Customized Diaphragm Pump Manufacturer. The customization process involves a dialogue with the manufacturer to align the pump's design with the specific operational risks and requirements of the process.

The sealless design of the diaphragm pump is a foundational feature that directly addresses critical operational concerns around safety, maintenance, and reliability. It is a technology that inherently reduces risk. To fully capitalize on this inherent advantage, engaging with a knowledgeable Customized Diaphragm Pump Manufacturer is a strategic step. Such a partnership is that the Customized Diaphragm Pump is not just a sealless device, but a precision-engineered solution optimized for the specific safety and performance demands of your unique operation.

English

English русский

русский Español

Español عربى

عربى