The Role of Diaphragm Oil Transfer Pumps in Streamlining Oil Handling Operations

2025.08.18

2025.08.18

Industry News

Industry News

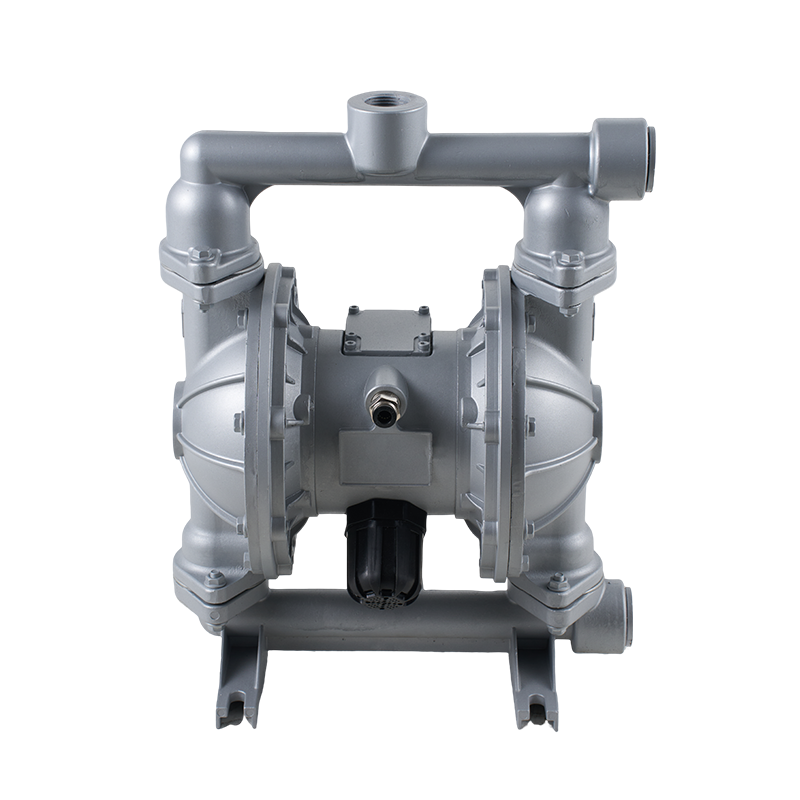

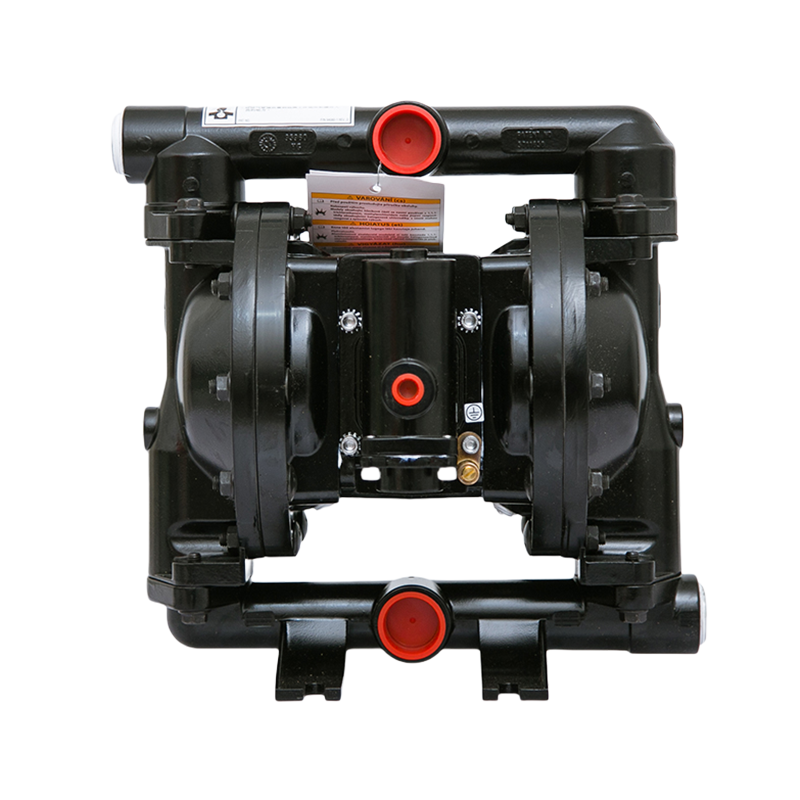

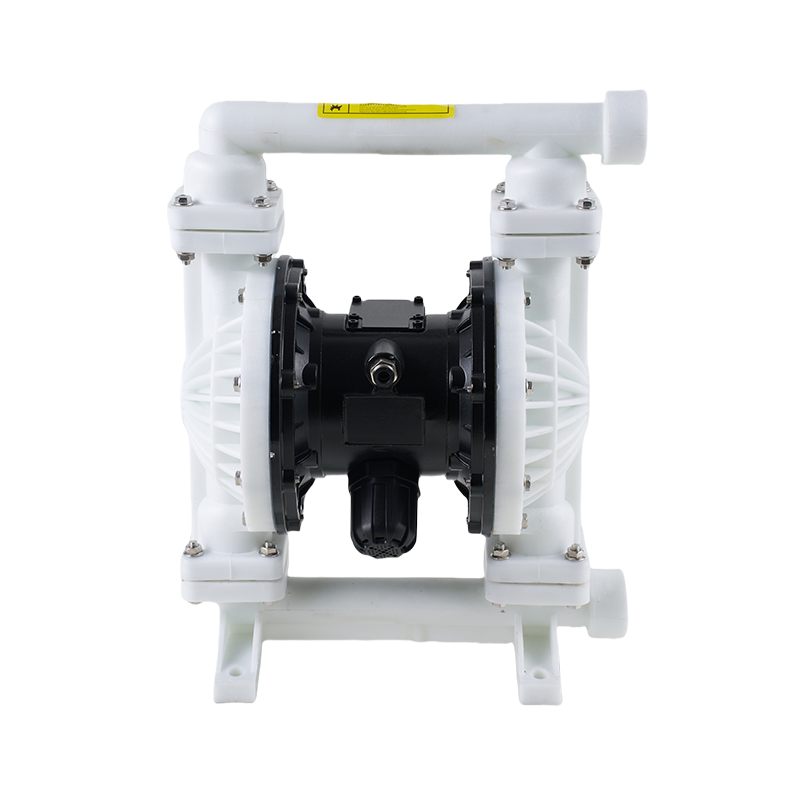

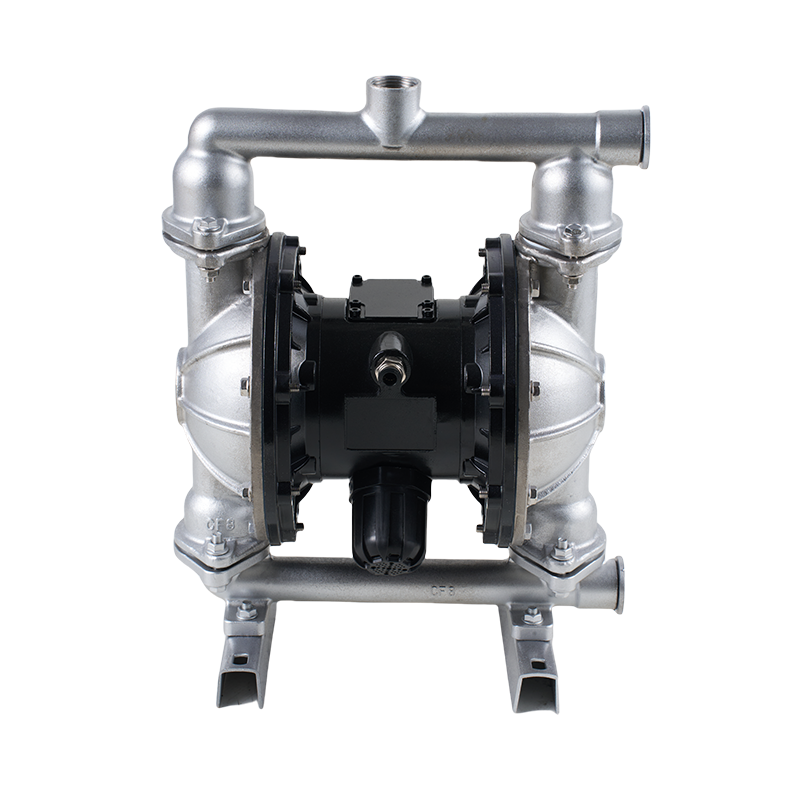

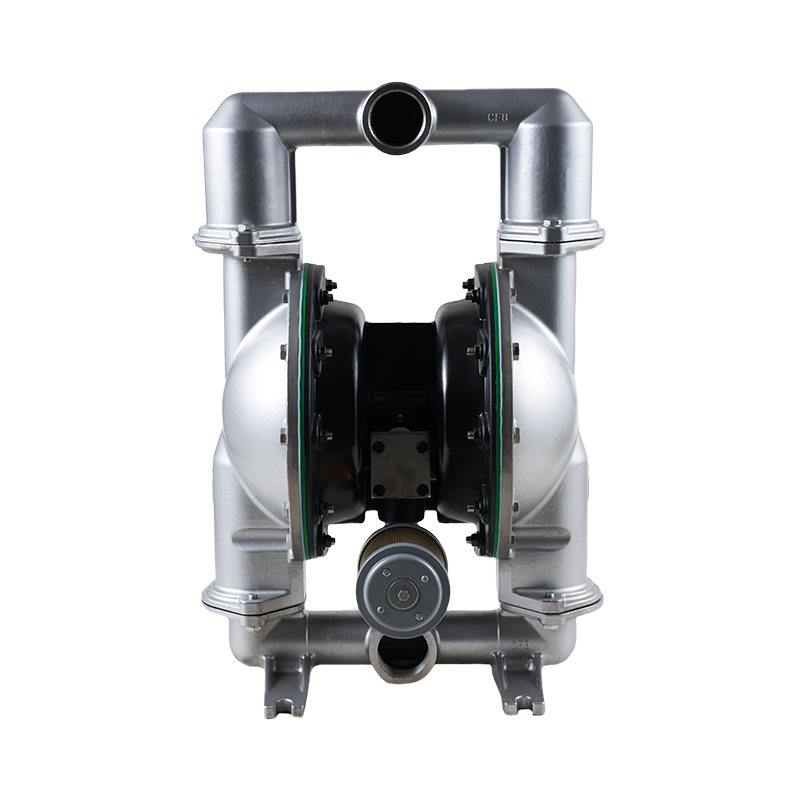

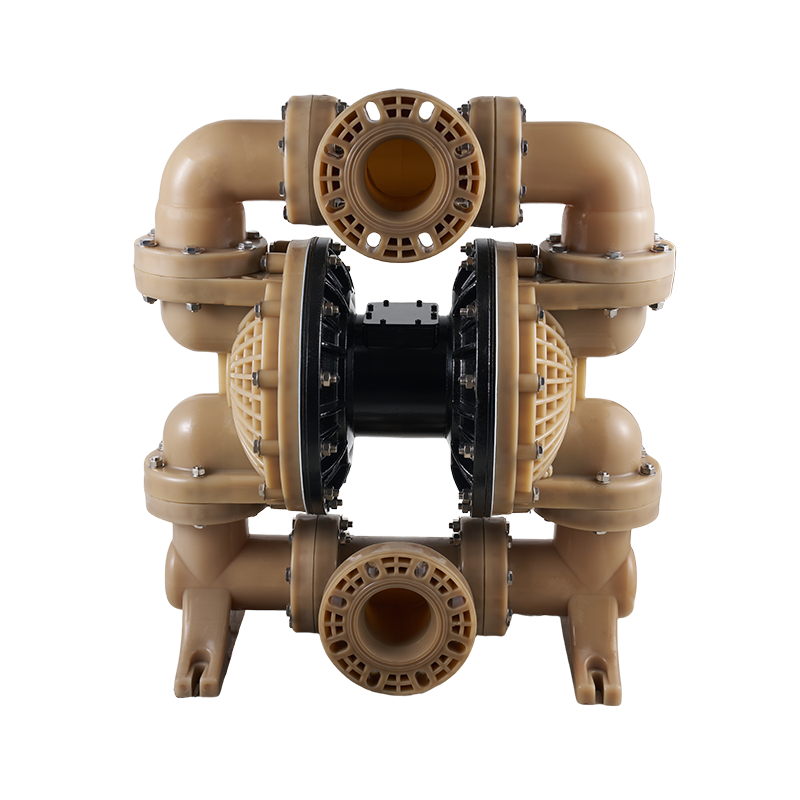

In the complex and high-stakes world of oil handling operations, efficiency, safety, and reliability are not just buzzwords—they are crucial elements that determine the success and sustainability of industrial processes. One often-overlooked yet indispensable piece of equipment that plays a pivotal role in achieving these goals is the diaphragm oil transfer pump. These pumps, specifically designed to handle a variety of oil-based substances, including waste oil, have become a cornerstone in modern oil-handling facilities.

Diaphragm oil transfer pumps are engineered to provide a seamless and efficient means of transferring oil from one location to another. Whether it's moving clean oil for processing or waste oil for disposal, these pumps offer a level of precision and control that is unmatched by many other technologies. The unique design of diaphragm pumps allows them to handle liquids with varying viscosities and even those containing small solid particles, making them incredibly versatile in a wide range of applications.

One of the significant advantages of diaphragm oil transfer pumps is their ability to operate without the risk of oil contamination. Unlike traditional centrifugal or gear pumps, which may experience internal leakage or mixing of fluids, diaphragm pumps use a flexible membrane to create a positive displacement action. This means that the oil being transferred is completely isolated from the pump's mechanical components, ensuring that it remains pure and uncontaminated throughout the transfer process. This feature is particularly important when dealing with waste oil diaphragm pumps, as it helps prevent cross-contamination and ensures that hazardous substances are handled safely and in compliance with environmental regulations.

In addition to their contamination-free operation, diaphragm oil transfer pumps are also highly efficient in terms of energy consumption. They are designed to operate at lower speeds and pressures compared to other types of pumps, which translates to reduced energy usage and lower operational costs. This efficiency is especially beneficial in large-scale oil-handling operations where the cumulative savings can be substantial. Moreover, the lower operating speeds also contribute to a longer lifespan for the pump, reducing the need for frequent maintenance and replacements.

Another key aspect of diaphragm oil transfer pumps is their ability to handle a wide range of flow rates and pressures. This flexibility makes them suitable for various applications, from small-scale oil-handling tasks to large-scale industrial operations. Whether it's transferring oil from storage tanks to processing units or from refineries to distribution centers, diaphragm pumps can be easily adjusted to meet the specific requirements of each task. This adaptability is crucial in an industry where the volume and type of oil being handled can vary significantly.

When it comes to safety, diaphragm oil transfer pumps are designed with multiple layers of protection. Their self-priming capabilities ensure that they can start and operate without the need for additional priming devices, reducing the risk of leaks and spills. Additionally, many modern diaphragm pumps come equipped with advanced safety features such as pressure relief valves and leak-detection systems. These features not only protect the pump itself but also ensure the safety of personnel and the environment by preventing accidents and minimizing the potential for oil spills.

The maintenance requirements of diaphragm oil transfer pumps are also relatively low compared to other types of pumps. Their simple design and fewer moving parts mean that there are fewer opportunities for mechanical failures. Regular inspection and replacement of the diaphragm and other wear-prone components are usually sufficient to keep the pump in working condition. This ease of maintenance translates to less downtime and higher overall productivity, which is essential in the fast-paced world of oil handling.

In the context of waste oil handling, diaphragm pumps play an even more critical role. Waste oil diaphragm pumps are specifically designed to handle the unique challenges associated with waste oil, such as its higher viscosity and potential for containing contaminants. These pumps ensure that waste oil is transferred safely and efficiently to treatment or disposal facilities, helping to minimize the environmental impact of industrial operations. By using diaphragm pumps for waste oil handling, companies can demonstrate their commitment to sustainability and responsible waste management practices.

As the oil industry continues to evolve and face new challenges, the role of diaphragm oil transfer pumps is becoming increasingly important. With their ability to handle a wide range of oils, including waste oil, their high efficiency, safety features, and low maintenance requirements, diaphragm pumps are proving to be an invaluable asset in streamlining oil-handling operations. Whether it's in the context of oil production, refining, or distribution, these pumps are helping companies achieve their operational goals while minimizing risks and efficiency.

Diaphragm oil transfer pumps are more than just a piece of equipment; they are a vital component in the modern oil-handling landscape. Their unique design and capabilities make them an ideal choice for transferring oil in a safe, efficient, and reliable manner. As the industry continues to seek innovative solutions to improve its processes and reduce its environmental footprint, diaphragm pumps are likely to remain at the forefront of oil-handling technology.

English

English русский

русский Español

Español عربى

عربى