The Rising Popularity of Air Operated Fluid Pumps in Waste Oil Management

2025.08.18

2025.08.18

Industry News

Industry News

In recent years, waste oil management has become an increasingly important part of industrial operations, automotive services, and environmental compliance programs. Companies are seeking reliable, efficient, and low-maintenance solutions to transfer, store, and dispose of used oils safely and cost-effectively. Among the various options available, the air operated fluid pump has gained significant attention for its ability to handle viscous and contaminated oils with minimal operational issues.

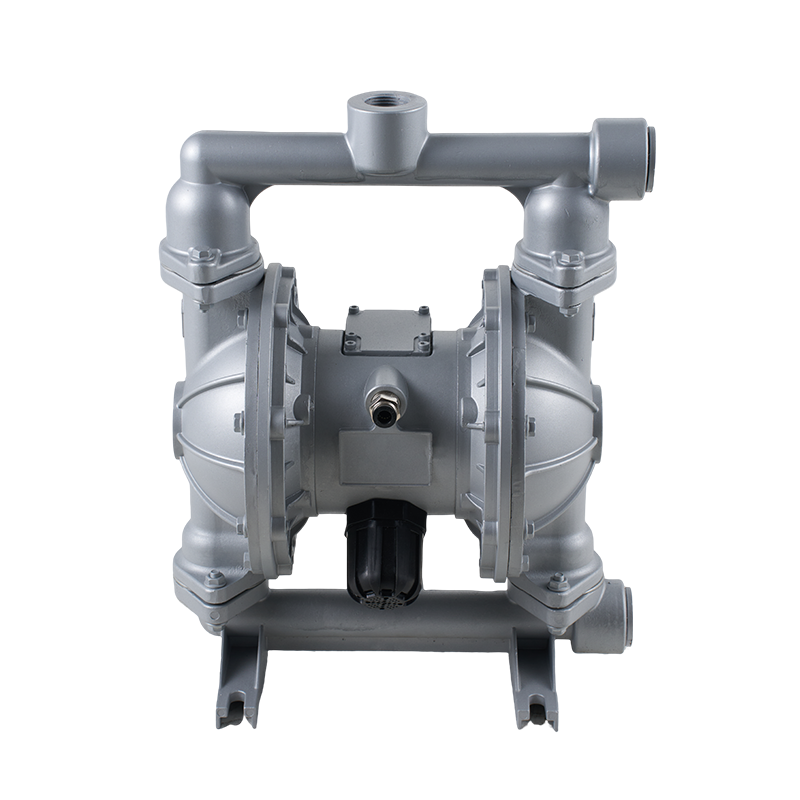

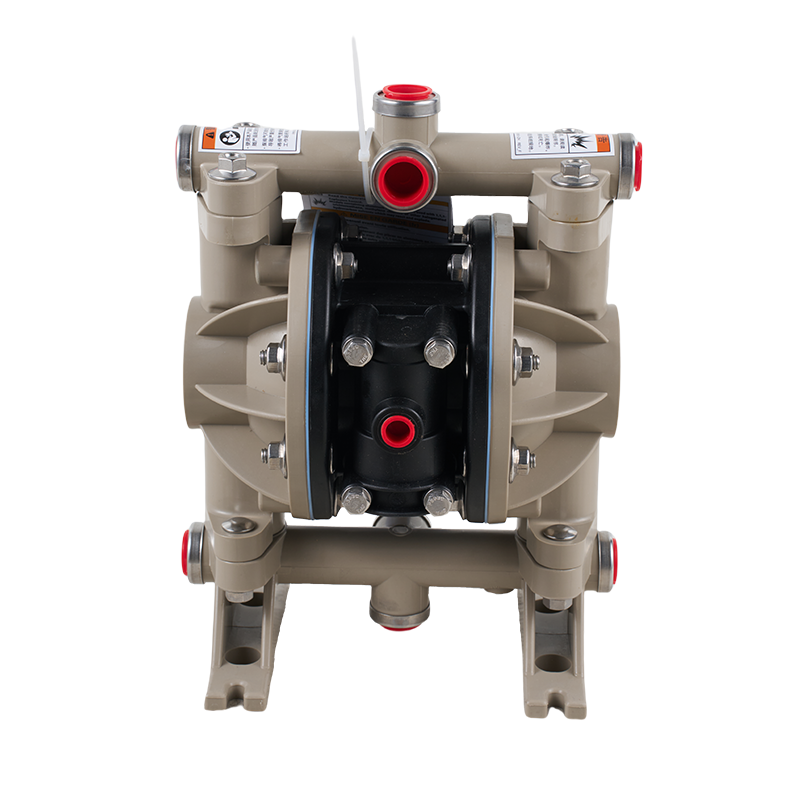

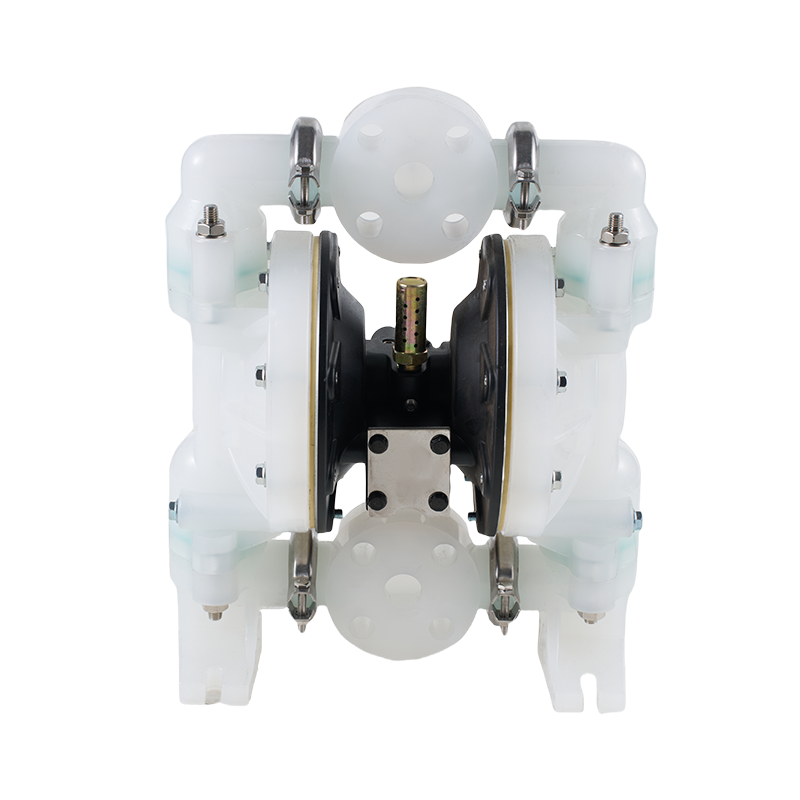

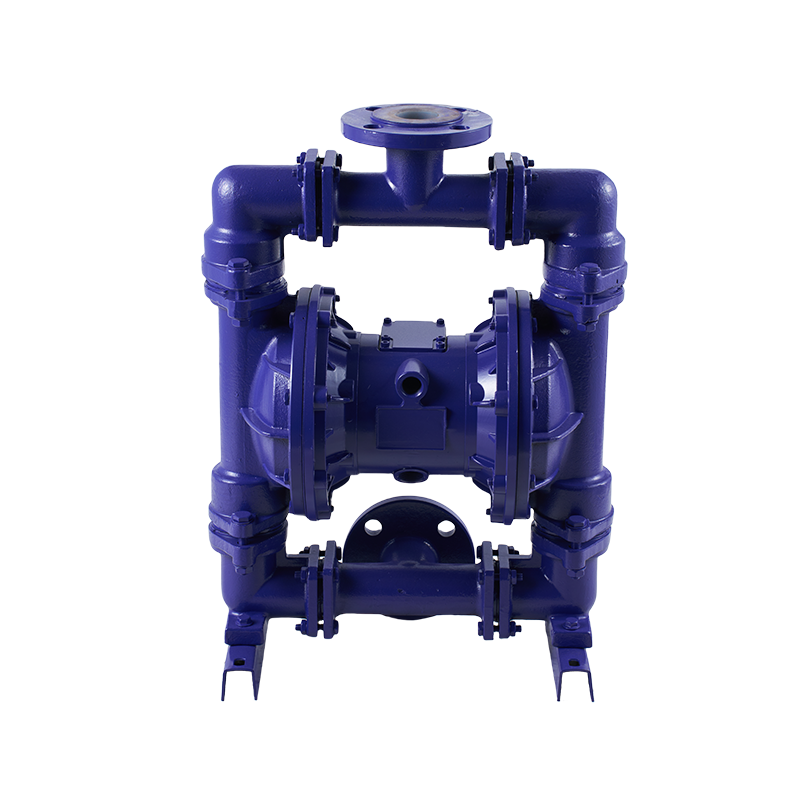

An air operated fluid pump uses compressed air as its power source, eliminating the need for electric motors in hazardous or flammable environments. This makes it particularly valuable in workshops, garages, and industrial facilities where safety and reliability are top priorities. In waste oil applications, the air-operated fluid pump is capable of moving fluids containing particles, sludge, and other impurities without causing excessive wear or blockages.

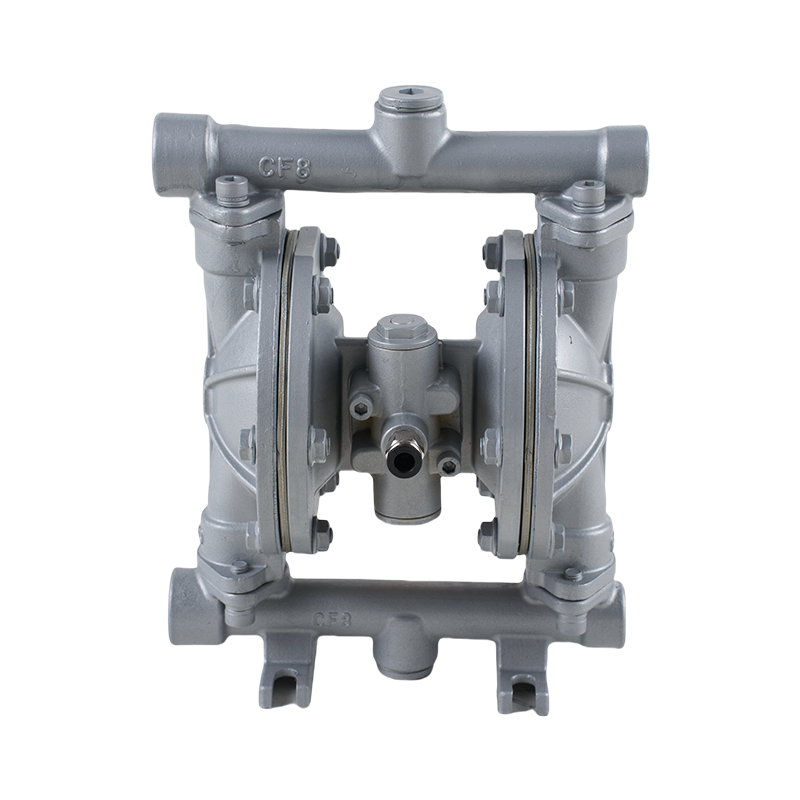

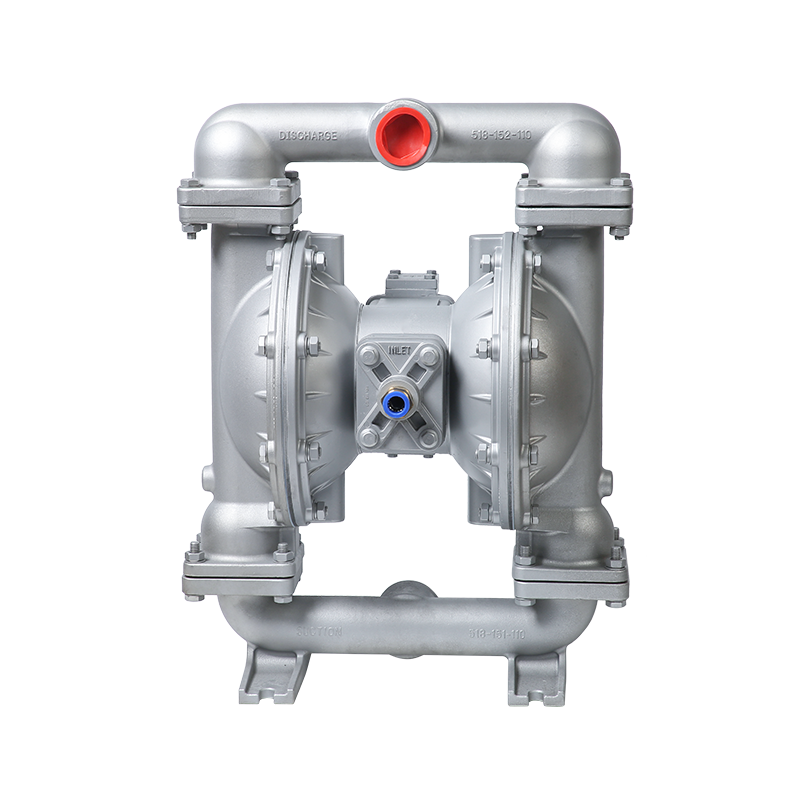

A key variation in this category is the air operated double diaphragm oil pump, which combines the air-driven mechanism with a dual-diaphragm design. This configuration offers suction capability, self-priming performance, and the ability to run dry without damage. The air operated double diaphragm oil pump is especially well-suited for waste oil handling because it can manage fluids with varying viscosities, from thin lubricants to heavy, sludge-laden oils.

The double diaphragm pump for waste oil is another trusted solution in the industry. Built for durability and resistance to wear, the double diaphragm pump for waste oil features components designed to withstand abrasive particles and chemical contaminants often found in used oils. Its simple mechanical design allows for quick maintenance, with service tasks requiring only basic tools and minimal downtime.

One of the main reasons for the growing adoption of the air operated fluid pump in waste oil management is its adaptability. Whether the task involves draining used oil from machinery, transferring waste oil to storage tanks, or feeding oil to recycling systems, the air operated fluid pump performs reliably in each role. This flexibility reduces the need for multiple specialized pumps, helping businesses optimize their equipment budgets.

The air operated double diaphragm oil pump also offers environmental benefits. Because it operates without mechanical seals or lubrication in the pump chamber, the risk of cross-contamination between the oil and pump components is minimized. This ensures cleaner waste oil collection and supports compliance with environmental disposal regulations. Additionally, the air operated double diaphragm oil pump can handle intermittent use without performance degradation, making it suitable for facilities with variable waste oil generation rates.

In heavy-duty applications, the double diaphragm pump for waste oil is often the preferred choice for its ruggedness and ability to handle demanding operating conditions. It is compatible with a wide range of waste oil types, including hydraulic oils, gear oils, and engine lubricants. Many industries, from automotive repair to marine services, rely on the double diaphragm pump for waste oil to ensure smooth waste oil transfer without the need for frequent repairs.

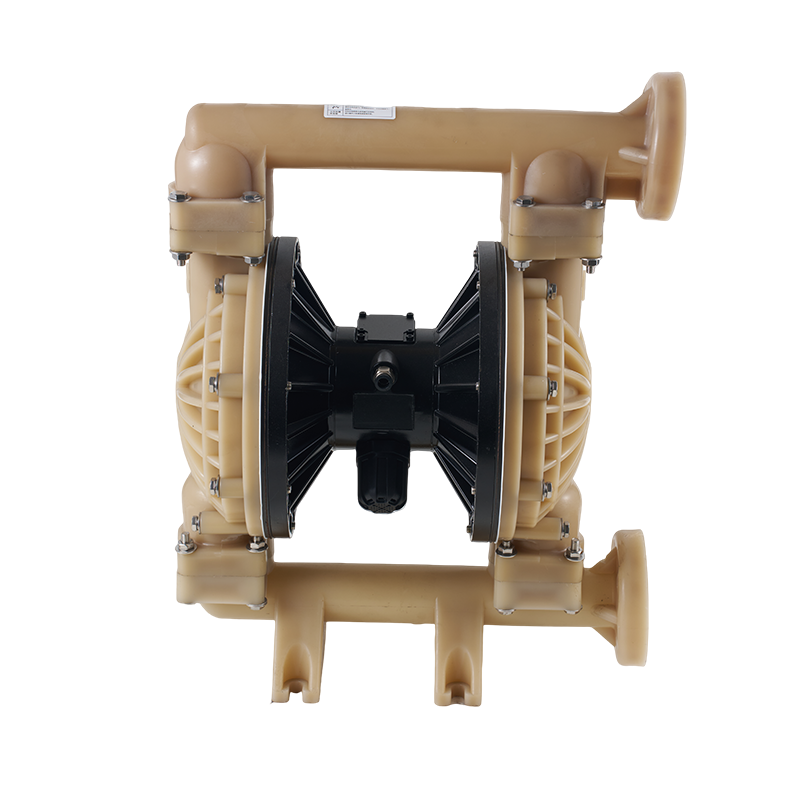

Market availability of these pumps is expanding, with numerous suppliers offering high-quality models tailored for waste oil applications. Businesses looking to upgrade their systems can find an air operated fluid pump or air operated double diaphragm oil pump in various sizes and material configurations. Similarly, the double diaphragm pump for waste oil is available in designs that meet both small-scale and high-volume operational needs.

As industries place more emphasis on sustainable waste management, the air operated fluid pump and its variations, including the air operated double diaphragm oil pump and double diaphragm pump for waste oil, are likely to remain integral tools in the process. Their reliability, ease of maintenance, and suitability for handling challenging fluids make them valuable assets in ensuring efficient, compliant, and cost-effective waste oil management.

English

English русский

русский Español

Español عربى

عربى