Troubleshooting Common Challenges with Double Diaphragm Oil Pumps

2025.08.18

2025.08.18

Industry News

Industry News

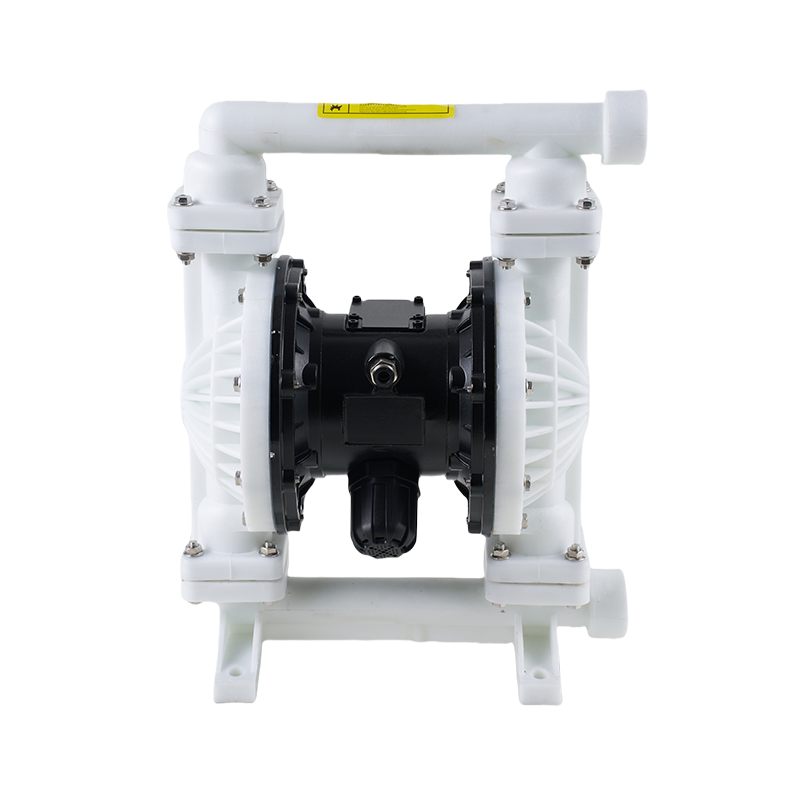

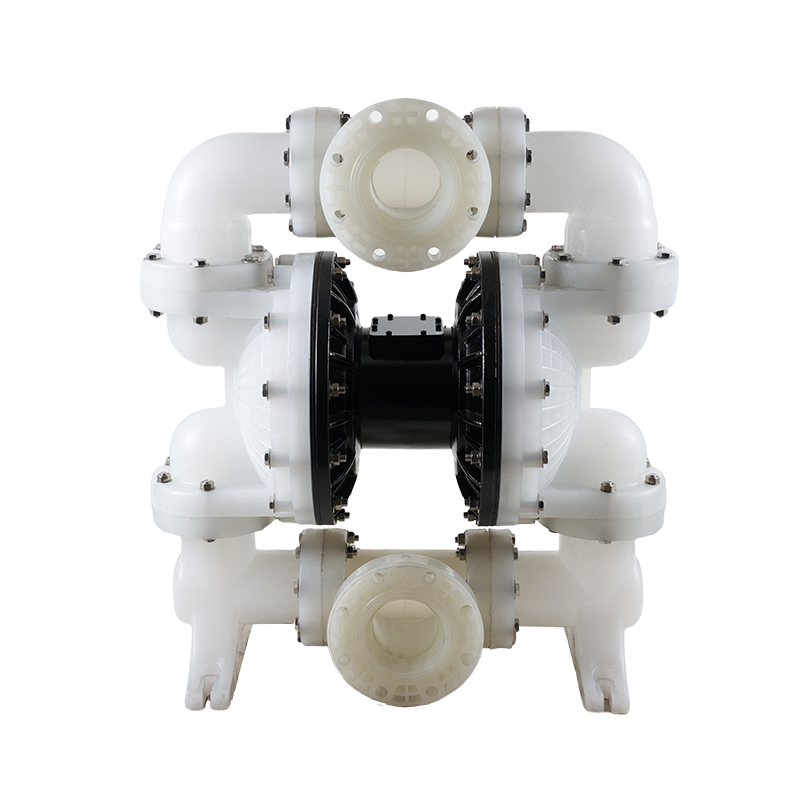

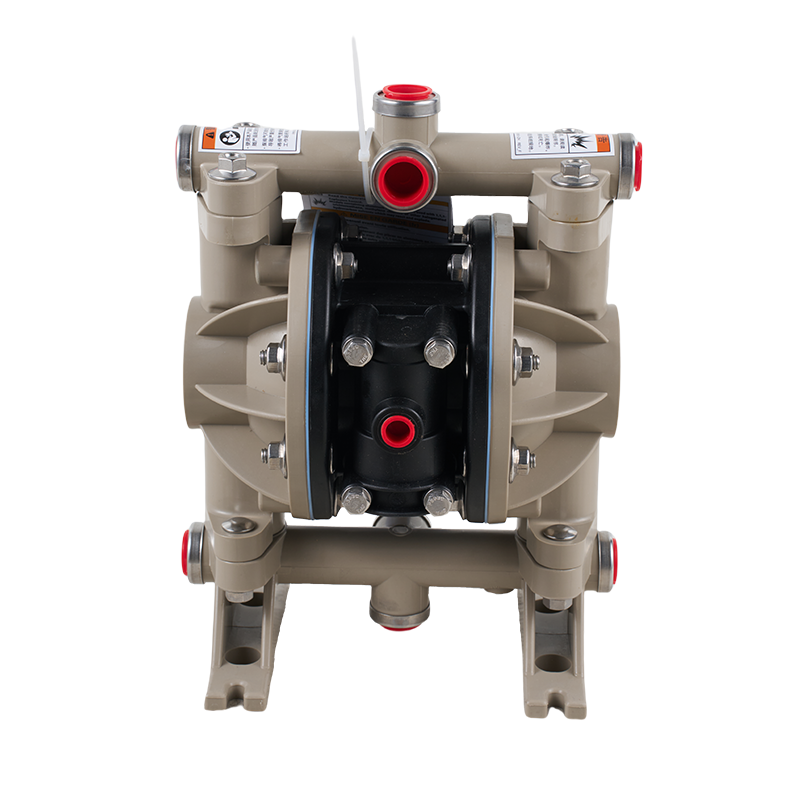

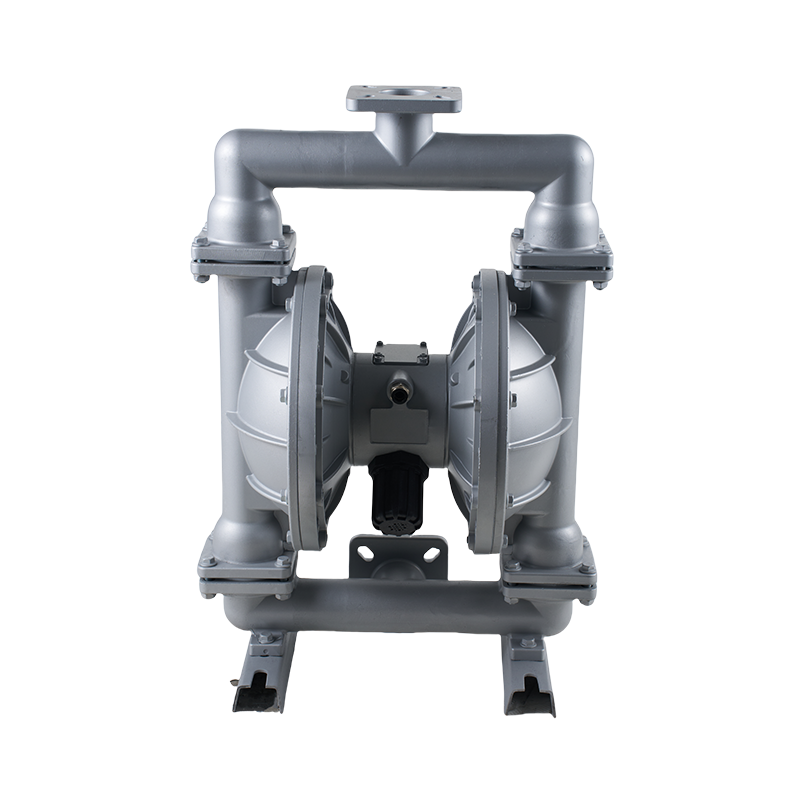

Double Diaphragm Oil Pumps (AODD pumps) are robust, versatile workhorses widely used for transferring various oils—from lubricants and fuels to hydraulic fluids and cutting oils. Their seal-less design, inherent safety, and ability to handle viscous fluids make them ideal for many industrial settings. However, like any mechanical system, Oil Transfer Diaphragm Pumps can encounter operational challenges. Understanding and effectively troubleshooting these issues is key to maintaining performance and minimizing costly downtime.

1. Loss of Prime or Failure to Start Pumping:

A frequent frustration is a Double Diaphragm Oil Pump failing to prime or losing prime during operation. This directly impacts the pump's core function: reliable oil transfer.

Check Valves: Worn, damaged, or fouled check valves (ball or flapper) are prime suspects. Oil residues or particulates can prevent them from sealing properly, allowing fluid to flow backward. Inspect, clean, or replace check valves. Ensure they are compatible with the specific oil type.

Air Supply Issues: Verify sufficient air pressure (consult manufacturer specs, often 60-100 PSI) and volume (CFM) are reaching the pump. Inspect air lines for kinks, blockages, or leaks. Ensure the air control system (filter, regulator, lubricator—FRL) is clean and functioning. Low air pressure is a common culprit for poor priming.

Suction Line Problems: Air leaks in the suction line or fittings are detrimental. Tighten connections and inspect hoses for cracks. Ensure the suction line is adequately sized (avoid undersizing) and submerged sufficiently below the oil level. A clogged suction strainer or foot valve will also prevent flow.

Oil Diaphragm: While less common as the initial cause for priming failure, a severely ruptured Oil Diaphragm can prevent pressure differentials from building correctly. Inspect diaphragms if other causes are ruled out.

2. Reduced Flow Rate or Output:

Experiencing lower-than-expected flow from your Oil Transfer Diaphragm Pump reduces efficiency.

Air Supply (Again): Insufficient air pressure or volume remains a top cause. Verify settings and line integrity.

Worn Valves: Partially stuck or worn check valves restrict flow in both directions. Listen for excessive chattering.

Restrictions: Check for blockages or kinks not only in the suction line but also in the discharge line. A partially closed valve downstream can mimic pump failure.

Viscosity Changes: AODD pump flow rates decrease as fluid viscosity increases. If pumping a colder or thicker oil than usual, expect reduced output. Ensure pump size matches the viscosity requirements.

Worn or Damaged Oil Diaphragm: While a complete rupture causes failure, a fatigued or slightly damaged Oil Diaphragm can to inefficient stroking and reduced displacement per cycle, lowering overall flow. Inspect diaphragms regularly.

Internal Wear: Over time, wear on the pump's liquid chambers or valve seats can increase internal recirculation, reducing net output.

3. Excessive Pulsation or Vibration:

While some pulsation is inherent to AODD pumps, excessive levels can stress piping and components.

Pulsation Dampeners: Ensure discharge (and sometimes suction) pulsation dampeners are correctly installed, charged to the proper pressure (typically 60-80% of average system pressure), and functional. Degraded dampener bladders fail to absorb pulses.

Air Supply Pulsation: An erratic air supply can cause irregular pump cycling. Ensure a steady air pressure source; sometimes a larger air receiver tank helps smooth flow.

Discharge Line Configuration: Long, rigid discharge lines amplify pulsation. Consider adding pipe supports, using flexible hose sections near the pump outlet, or installing additional dampeners.

Air Valve Issues: A malfunctioning or dirty air spool/distribution valve can cause uneven or erratic air delivery to the diaphragms, to irregular, potentially violent stroking. Service the air valve assembly.

4. External Leakage:

Leaks compromise safety, create messes, and waste product.

Manifold/Cover Seals: Inspect O-rings and gaskets on the liquid end covers and manifold. Replace if damaged, flattened, or cracked. Tighten bolts evenly to the specified torque.

Port Connections: Tighten inlet and outlet pipe connections. Replace thread sealant or gaskets as needed.

Oil Diaphragm Failure: This is a critical failure point. A ruptured Oil Diaphragm will allow oil to leak into the air end (often seen venting from the exhaust muffler) or, less commonly, externally if the failure is at the clamping edge. Immediately replace ruptured diaphragms. Investigate the cause—chemical incompatibility, excessive pressure, abrasive fluids, or fatigue.

5. Diaphragm Failure (The Core Component):

Premature Oil Diaphragm failure is perhaps the significant challenge specific to Double Diaphragm Oil Pumps.

Chemical Compatibility: This is paramount. Ensure the diaphragm material (e.g., Buna-N, Viton, EPDM, PTFE, Hytrel) is fully compatible with the specific oil being pumped. Chemical attack softens, swells, or cracks diaphragms. Consult chemical resistance charts meticulously.

Abrasion: Oils containing particulates, metal fines, or grit act like sandpaper on the diaphragm. Use appropriate suction strainers and consider hardened diaphragm materials if abrasives are unavoidable.

Temperature: Exceeding the diaphragm material's temperature rating accelerates aging and brittleness. Monitor oil temperature.

Pressure Surges: Water hammer or sudden pressure spikes (especially on the discharge side) can rupture diaphragms. Pulsation dampeners help mitigate this.

Dry Running: Operating a Double Diaphragm Oil Pump without fluid can cause excessive heat and friction, rapidly destroying the Oil Diaphragm. Always ensure an adequate fluid supply. Consider run-dry protection devices.

Fatigue: Diaphragms flex millions of times. Even with conditions, they eventually fatigue and fail. Adhere to recommended preventive replacement schedules based on operating hours or observed condition.

Proactive Maintenance is Key:

Troubleshooting is reactive; prevention is better. Implement a robust maintenance schedule for your Oil Transfer Diaphragm Pump:

Regularly inspect Oil Diaphragms for signs of wear, cracking, swelling, or distortion. Replace per schedule or condition.

Periodically check and clean check valves and valve seats.

Service the air filter, regulator, and lubricator (FRL unit) regularly.

Inspect and replace manifold seals and O-rings during diaphragm changes.

Verify air pressure settings and line integrity.

Keep suction strainers clean.

Ensure the pump is correctly sized for the oil viscosity and flow requirements.

By systematically addressing these common challenges—paying particular attention to the critical Oil Diaphragm and ensuring proper air supply and valve function—operators can maximize the reliability, efficiency, and lifespan of their Double Diaphragm Oil Pumps, ensuring these versatile Oil Transfer Diaphragm Pump units continue to perform their vital role effectively and safely.

English

English русский

русский Español

Español عربى

عربى