Understanding Double Diaphragm Pump

2025.09.12

2025.09.12

Industry News

Industry News

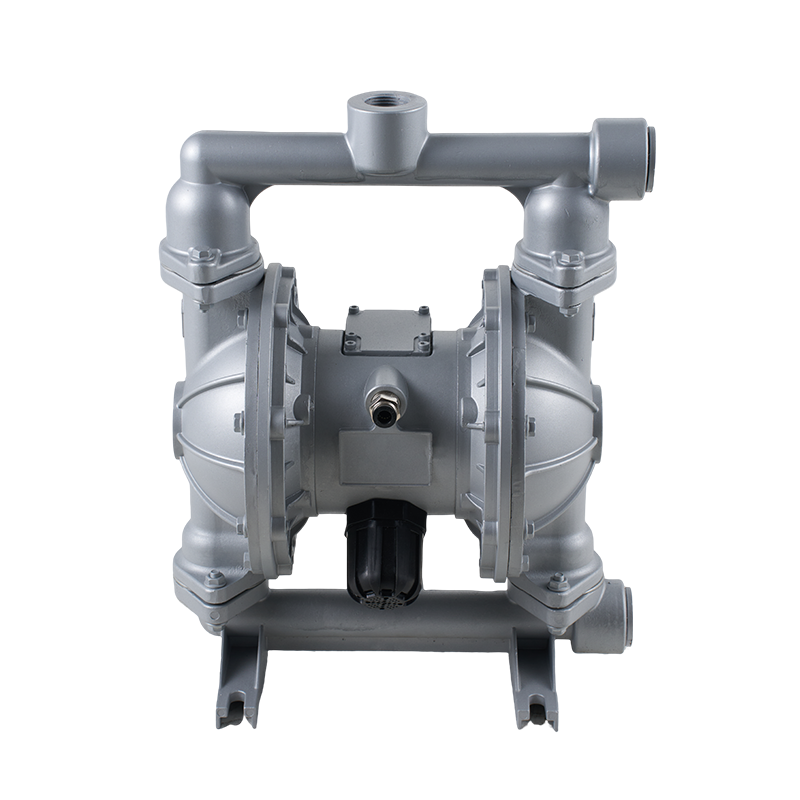

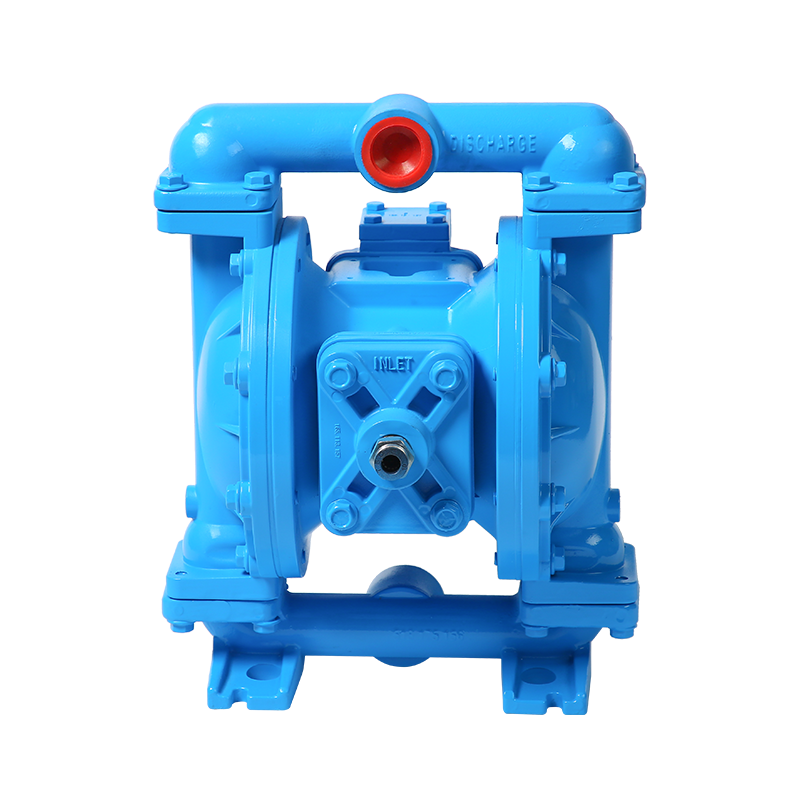

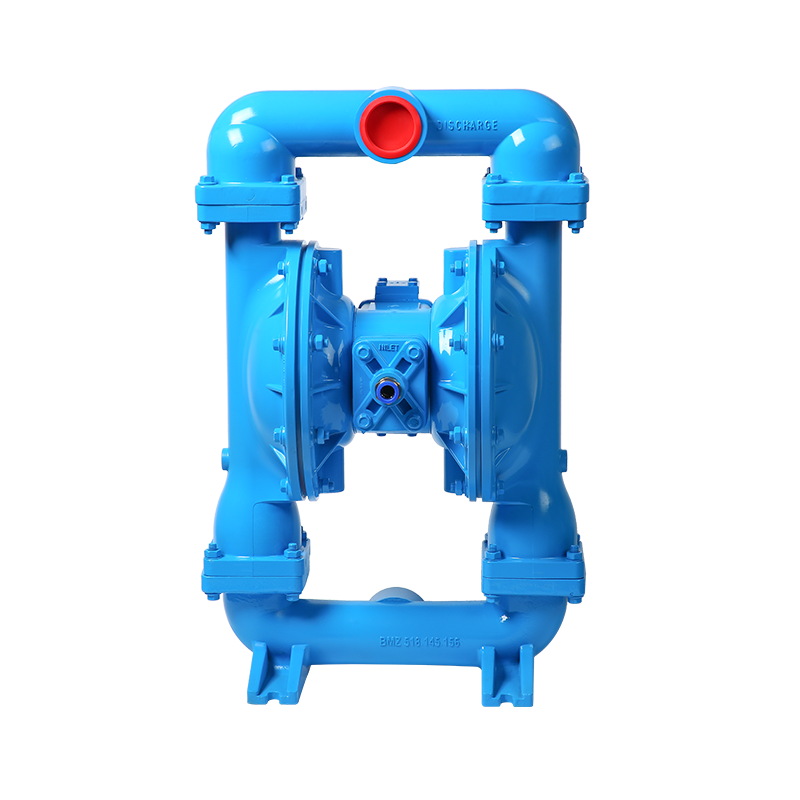

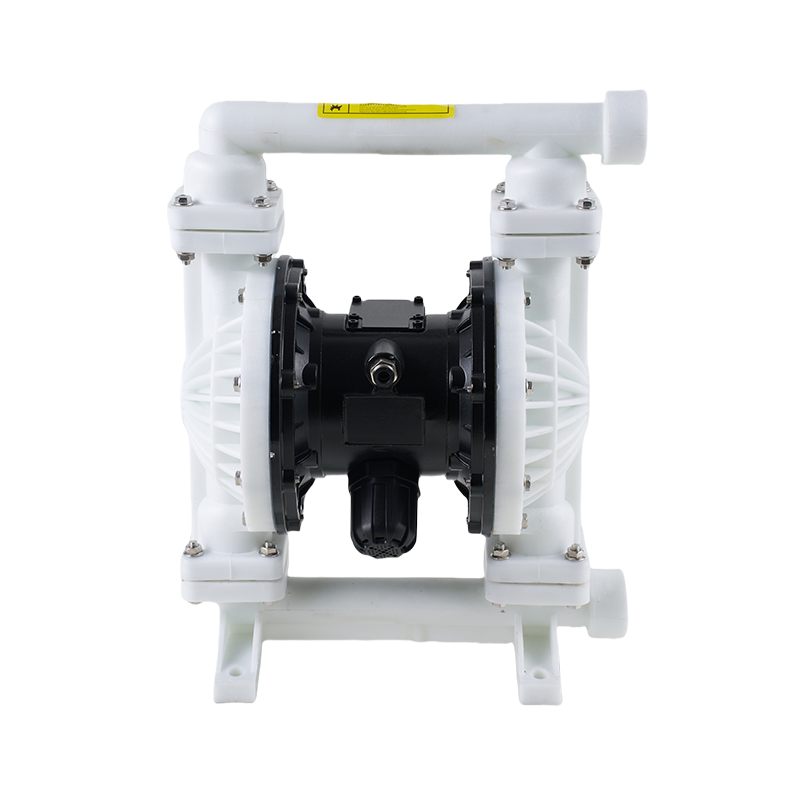

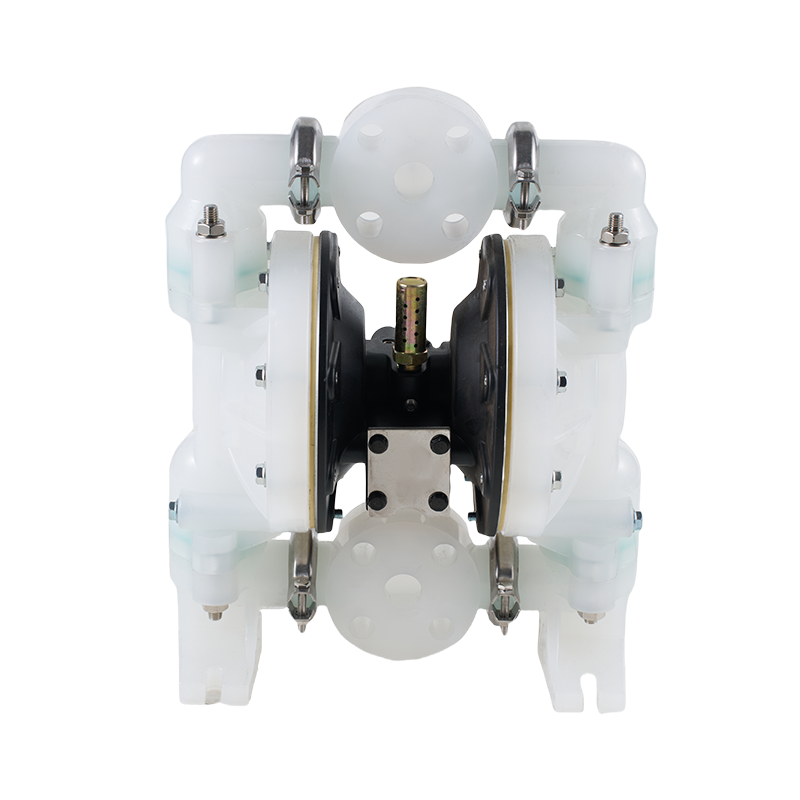

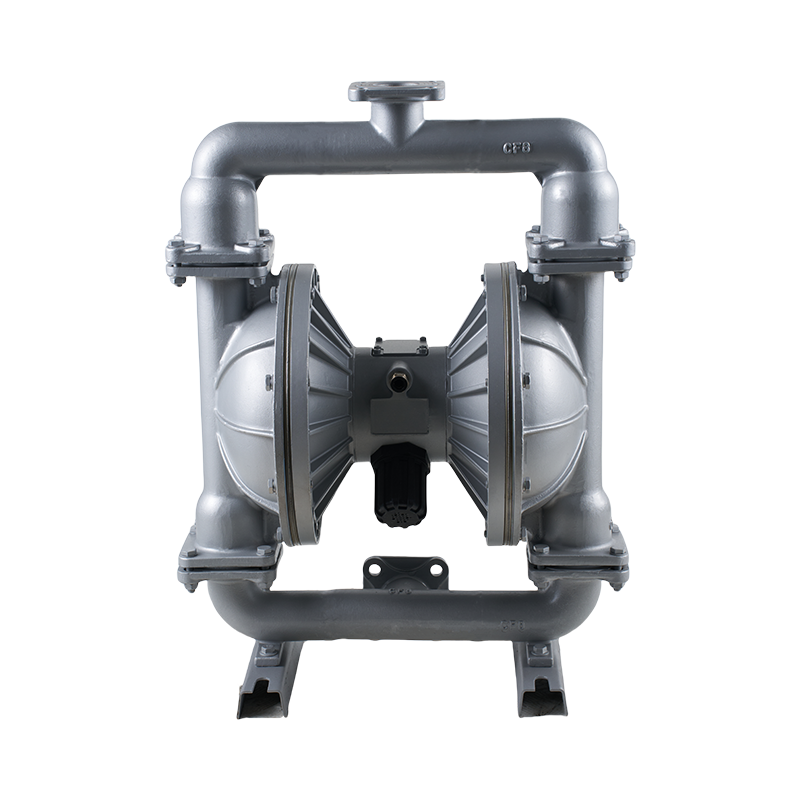

When considering fluid transfer solutions, the Double Diaphragm Pump often emerges as a reliable and versatile option. Many users have questions about its operation, types, and the materials used for its diaphragms. This article addresses these queries in detail, providing a clear understanding of this essential pump.

How does a double diaphragm pump work?

The Double Diaphragm Pump operates using two flexible diaphragms that move back and forth within the pump chambers. When one diaphragm moves outward, it creates a vacuum that draws fluid into the chamber. Simultaneously, the other diaphragm moves inward, pushing fluid out through the discharge valve. This alternating motion ensures a continuous flow without the need for a mechanical seal, which reduces the risk of leaks and enhances durability.

Air-operated double diaphragm pumps (AODD) are the common type, using compressed air to drive the diaphragms. The air shifts from one side to the other via a valve, creating the necessary pumping action. Electric-driven versions rely on a motor to move the diaphragms mechanically or hydraulically. Regardless of the driving method, the working principle remains consistent: creating alternating suction and discharge through the synchronized movement of the diaphragms.

What are the main types of double diaphragm pumps?

The Double Diaphragm Pump comes in several types, primarily based on the driving mechanism and application requirements. The widely used type is the air-operated double diaphragm (AODD) pump, which is valued for its ability to handle abrasive, viscous, or chemically aggressive fluids. These pumps are often portable, require no electricity, and can operate in hazardous environments.

Electric double diaphragm pumps are another type, offering precise control over flow rates and often used in industrial settings where compressed air is not convenient. Within both air-operated and electric versions, further variations exist, including metallic pumps for high-pressure applications and plastic or rubber models for chemical resistance. Each type is selected based on fluid characteristics, desired flow rate, and operational conditions.

What materials are used for the diaphragms?

The diaphragms of a Double Diaphragm Pump are critical components that determine its chemical compatibility, durability, and overall performance. Common diaphragm materials include rubber, PTFE (Teflon), Santoprene, and neoprene. Rubber diaphragms offer flexibility and cost-effectiveness for general applications, while PTFE diaphragms provide exceptional chemical resistance, suitable for aggressive or corrosive fluids.

Santoprene diaphragms combine flexibility with chemical resistance, making them a popular choice for food-grade applications or where durability under repetitive cycles is essential. The selection of diaphragm material depends on the fluid being pumped, temperature, and operating pressure. Using the correct diaphragm material ensures longer service life and reduces maintenance frequency.

Understanding the Double Diaphragm Pump involves knowing how it works, the types available, and the materials used for diaphragms. It operates through the alternating motion of two diaphragms, creating a continuous and leak-free flow. There are various types, including air-operated and electric pumps, each suitable for different applications. The diaphragm materials, such as rubber, PTFE, and Santoprene, must be chosen carefully to ensure chemical compatibility and long-term performance.

Whether for industrial chemical transfer, food processing, or general fluid handling, the Double Diaphragm Pump offers a versatile, reliable, and durable solution for many fluid transfer needs. By understanding these key aspects, users can select the right pump and maintain it effectively for consistent operation.

English

English русский

русский Español

Español عربى

عربى