The Inner Workings of a Diaphragm Pump

2025.09.05

2025.09.05

Industry News

Industry News

A Diaphragm Pump is an essential piece of equipment in various industrial and commercial applications. Its unique design and operation make it highly versatile and efficient for transferring fluids, even those with challenging properties. Understanding how a Diaphragm Pump works can provide valuable insights into its capabilities and limitations.

At the heart of a Diaphragm Pump is the diaphragm itself. This flexible membrane plays a crucial role in the pumping process. The diaphragm moves back and forth, creating a temporary chamber that alternately expands and contracts. When the diaphragm moves outward, it creates a vacuum, drawing fluid into the pump chamber. As the diaphragm moves inward, the chamber volume decreases, increasing the pressure and forcing the fluid out through the discharge port. This simple yet effective mechanism allows the Diaphragm Pump to handle a wide range of fluids, including those with high viscosity or containing solid particles.

The air valve in a Diaphragm Pump is another key component that ensures smooth and efficient operation. The air valve controls the flow of air or gas that drives the diaphragm's movement. When the air valve opens, air enters the pump's air chamber, pushing the diaphragm and creating suction on one side. Simultaneously, the other diaphragm is pushed outward, expelling fluid from the pump. The air valve then switches, allowing the air to enter the other air chamber and reversing the diaphragm movement. This reciprocating action continues, maintaining a steady flow of fluid through the Diaphragm Pump.

One of the significant advantages of a Diaphragm Pump is its ability to self-prime. This means it can create a vacuum strong enough to draw fluid into the pump chamber without the need for an external priming device. This self-priming capability makes Diaphragm Pumps ideal for applications where the fluid level may fluctuate or where the pump is located above the fluid source.

Diaphragm Pumps are also known for their dry-running capability. Unlike some other pump types, they can operate without fluid in the pump chamber for short periods without causing damage. This feature is particularly useful in applications where fluid supply may be intermittent or where the pump needs to be cleaned or flushed.

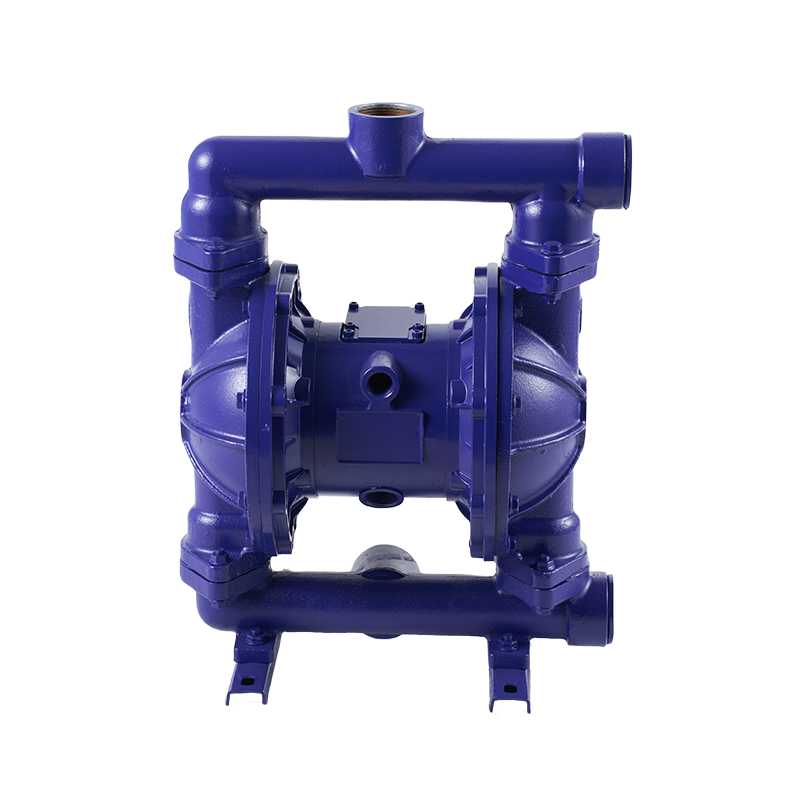

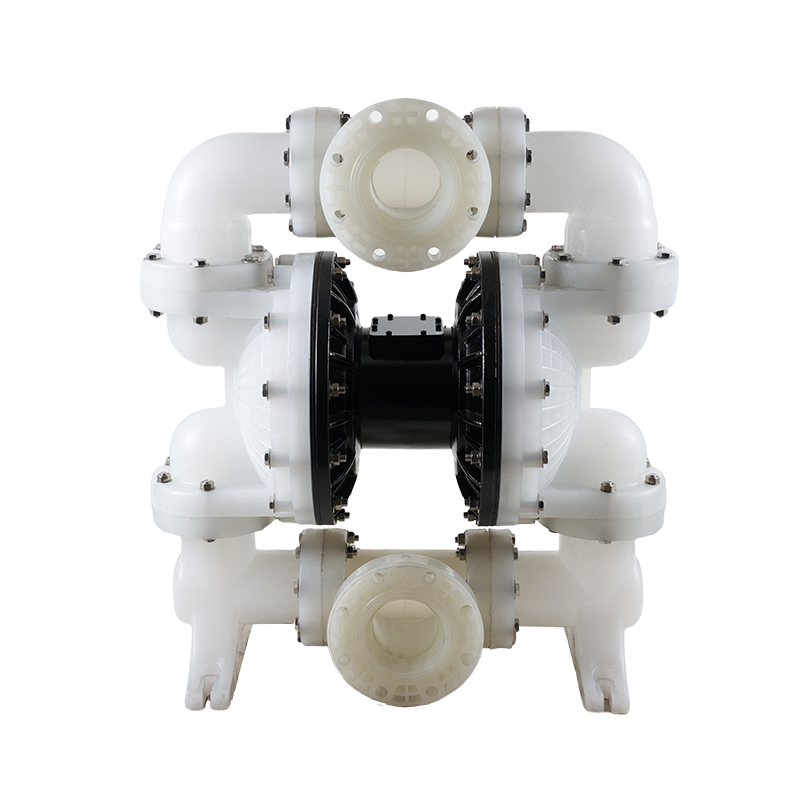

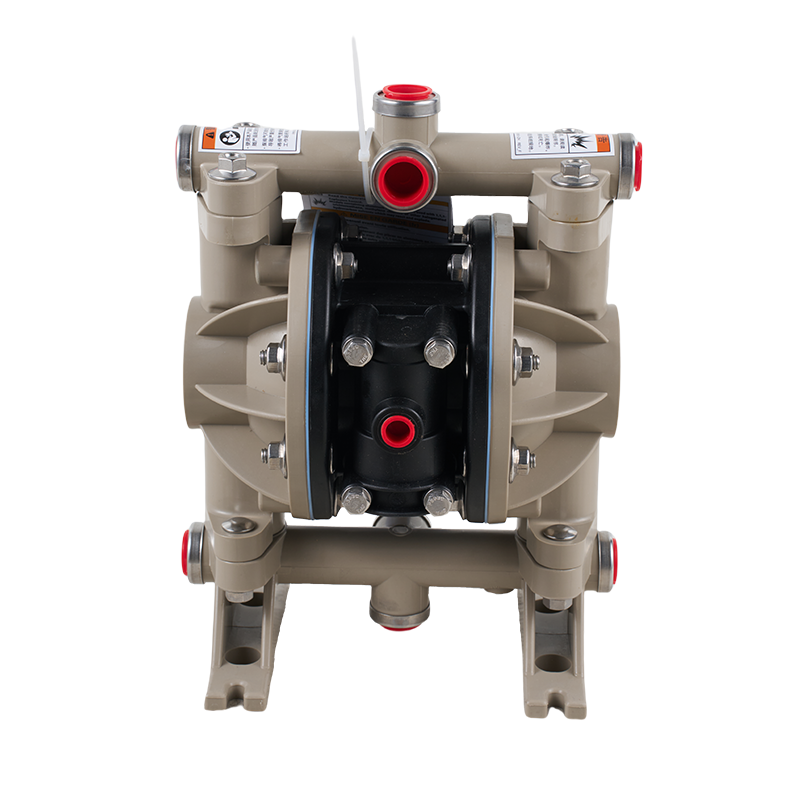

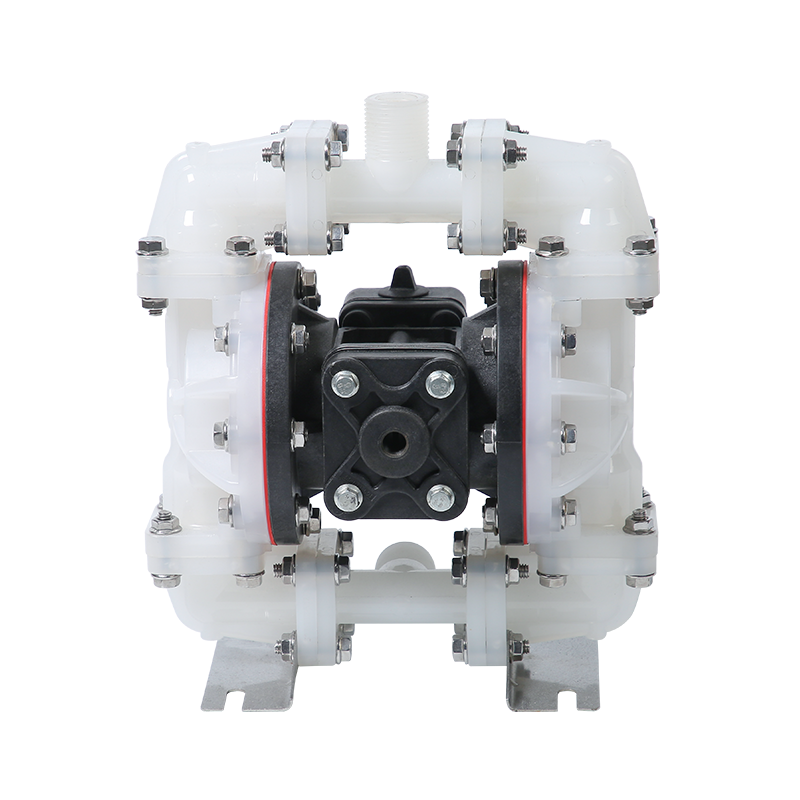

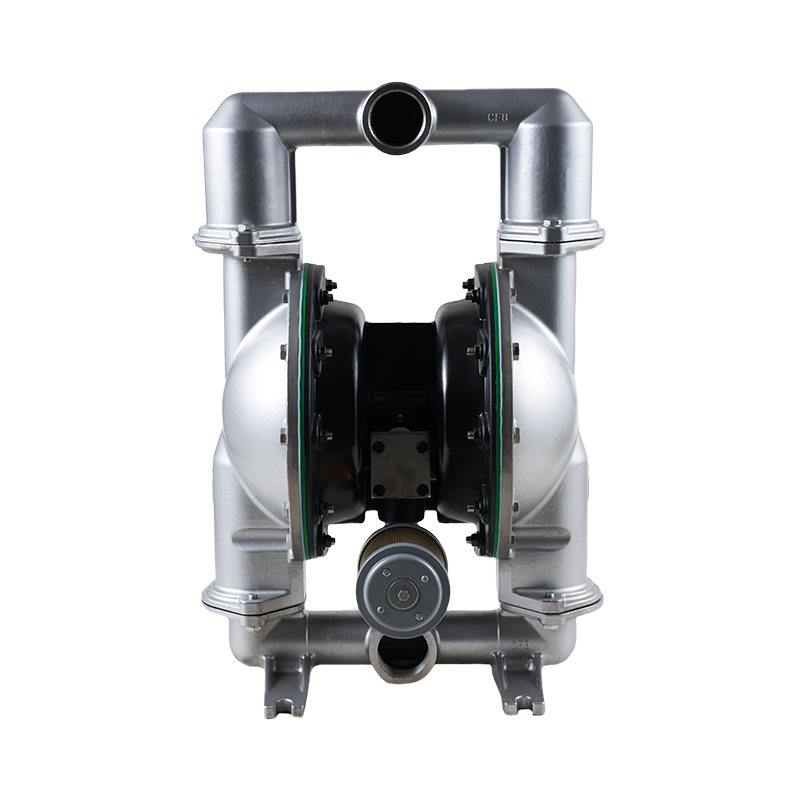

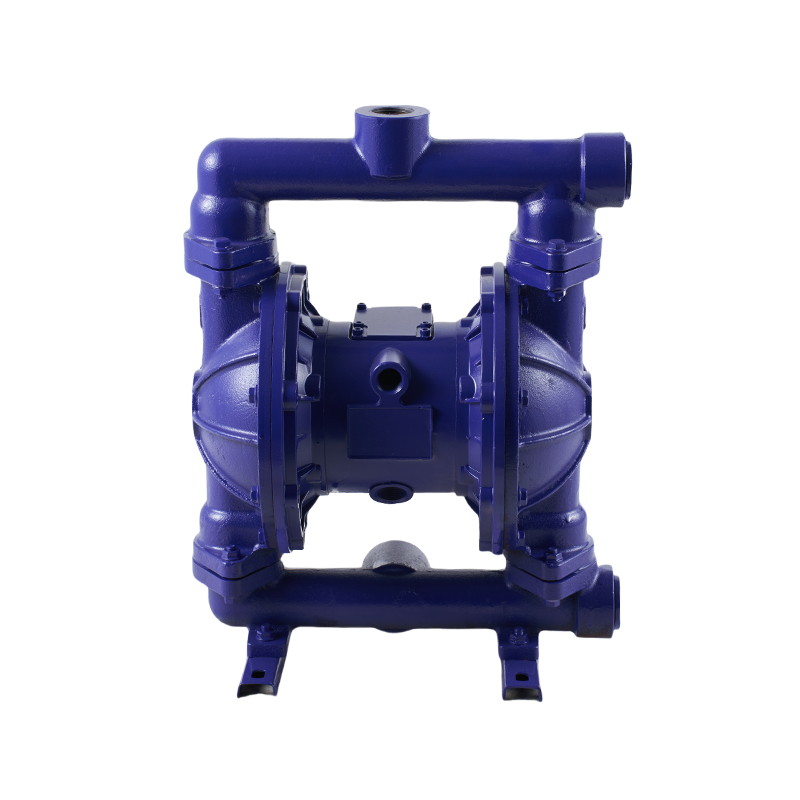

The construction materials of a Diaphragm Pump are chosen based on the specific application and the type of fluid being handled. Common materials include stainless steel, aluminum, and various plastics. Stainless steel is often used for its corrosion resistance, making it suitable for handling aggressive chemicals. Aluminum is lightweight and cost-effective, while plastics offer chemical resistance and are ideal for handling corrosive fluids.

In terms of maintenance, Diaphragm Pumps are relatively low-maintenance devices. However, regular inspection and timely replacement of worn components, such as diaphragms and valves, are essential to ensure performance and longevity. The diaphragms, in particular, are subject to wear and tear due to their constant movement. Signs of wear may include reduced flow rates or increased air consumption.

When selecting a Diaphragm Pump for a specific application, several factors must be considered. These include the type of fluid being pumped, the required flow rate and pressure, the presence of solid particles in the fluid, and the operating environment. For example, a Diaphragm Pump designed for transferring water will have different specifications than one intended for pumping viscous oils or corrosive chemicals.

A Diaphragm Pump operates through the reciprocating action of a flexible diaphragm, driven by an air valve that controls the flow of air or gas. Its ability to self-prime, handle a wide range of fluids, and operate without fluid for short periods makes it a versatile and reliable choice for many applications. With proper maintenance and appropriate material selection, a Diaphragm Pump can provide efficient and trouble-free service for years.

English

English русский

русский Español

Español عربى

عربى