Why Double Diaphragm Pumps Are Ideal for Thick, Abrasive Mud Applications?

2025.08.17

2025.08.17

Industry News

Industry News

In the rugged world of industrial applications, especially those involving thick, abrasive mud, finding the right pumping solution is crucial. Traditional pumps often struggle with such demanding materials, frequent breakdowns, high maintenance costs, and inefficient operations. However, the advent of Double Diaphragm Pumps has revolutionized the way industries handle these challenging fluids. This article delves into why Double Diaphragm Pumps are the ideal choice for thick, abrasive mud applications.

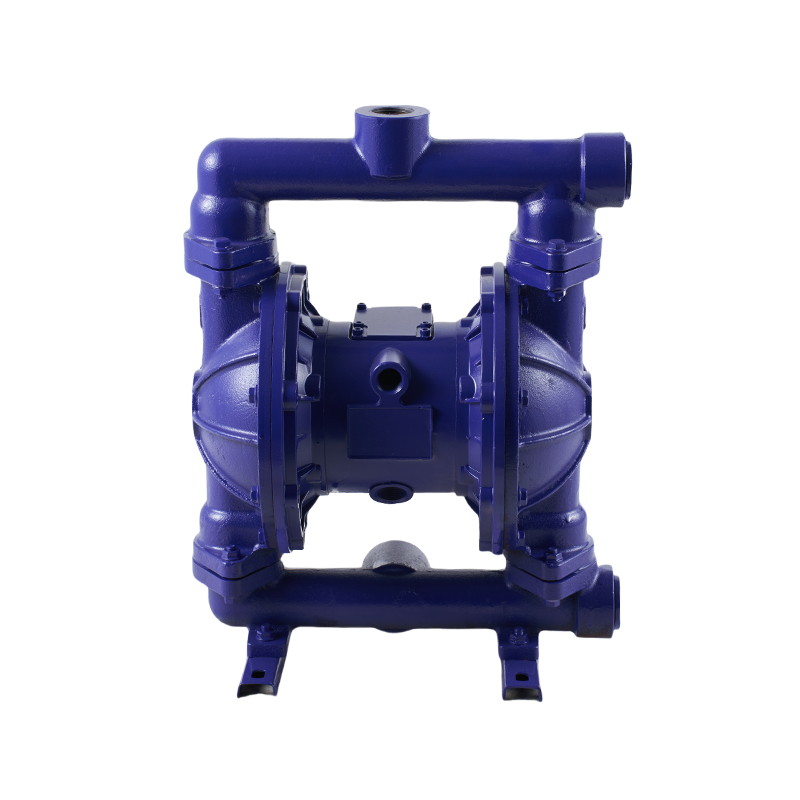

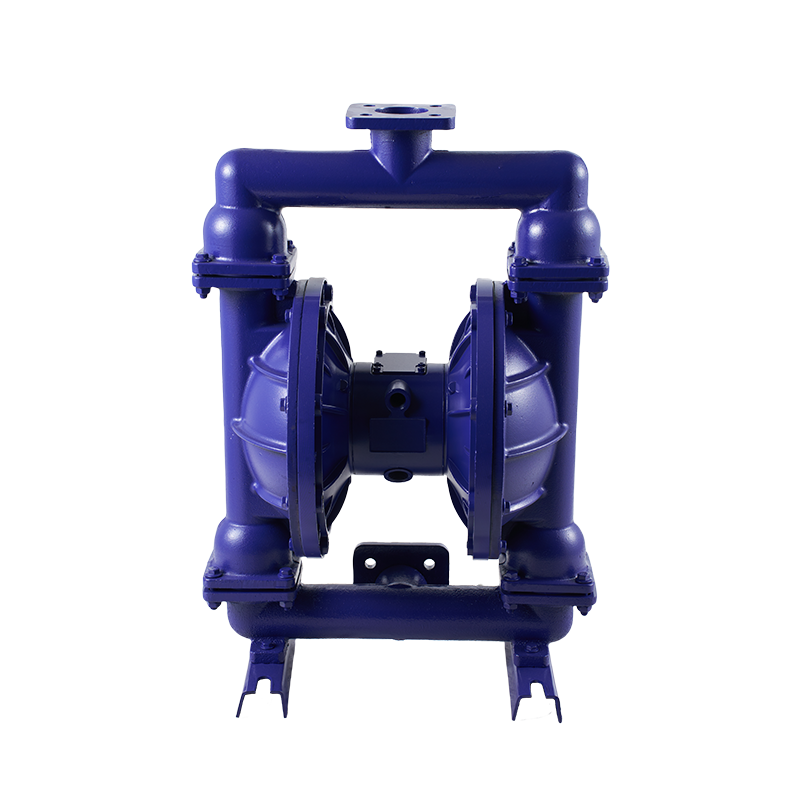

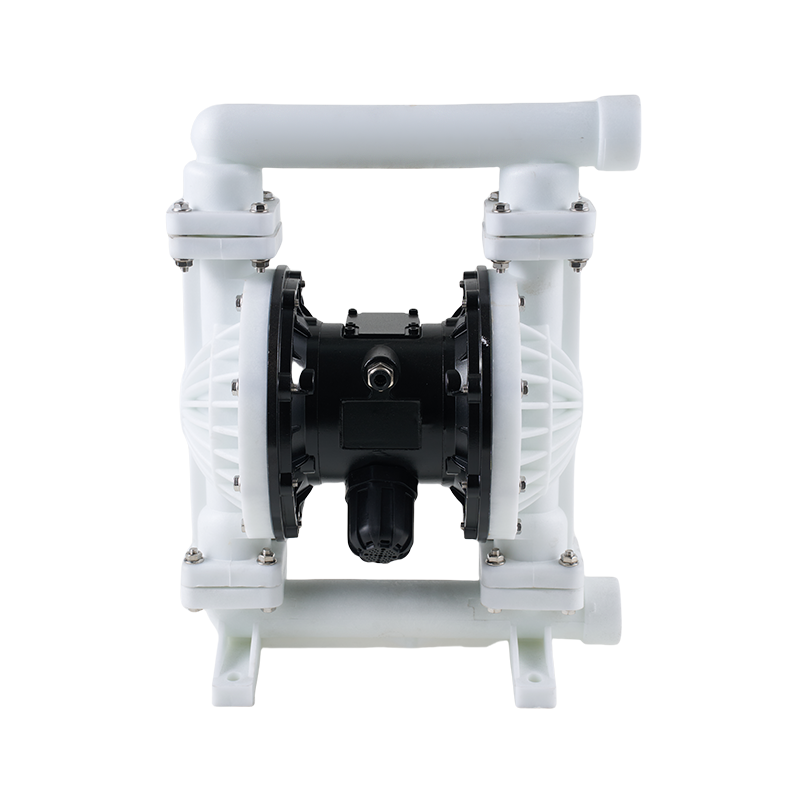

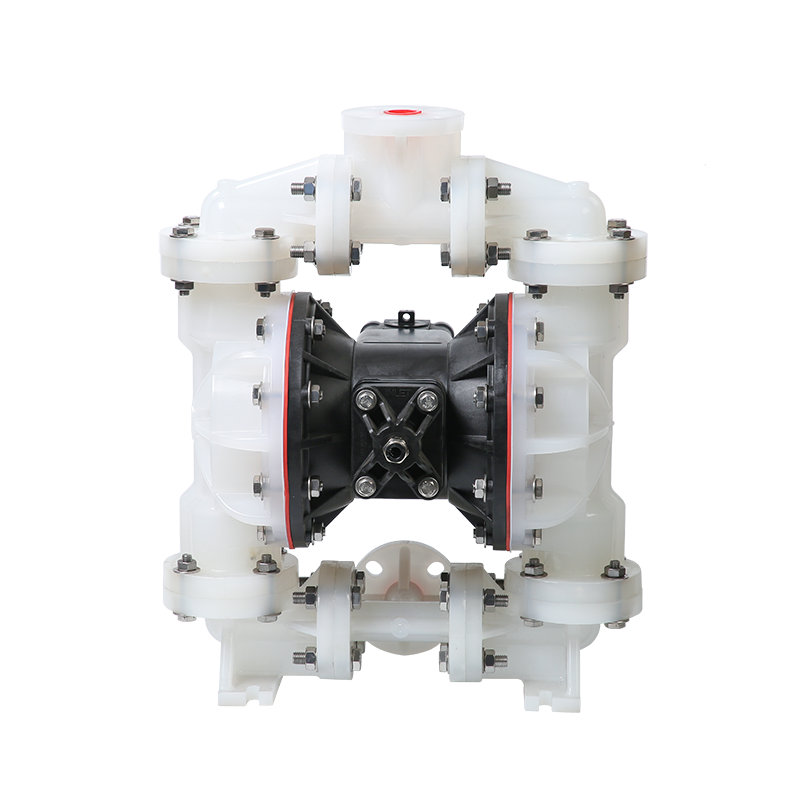

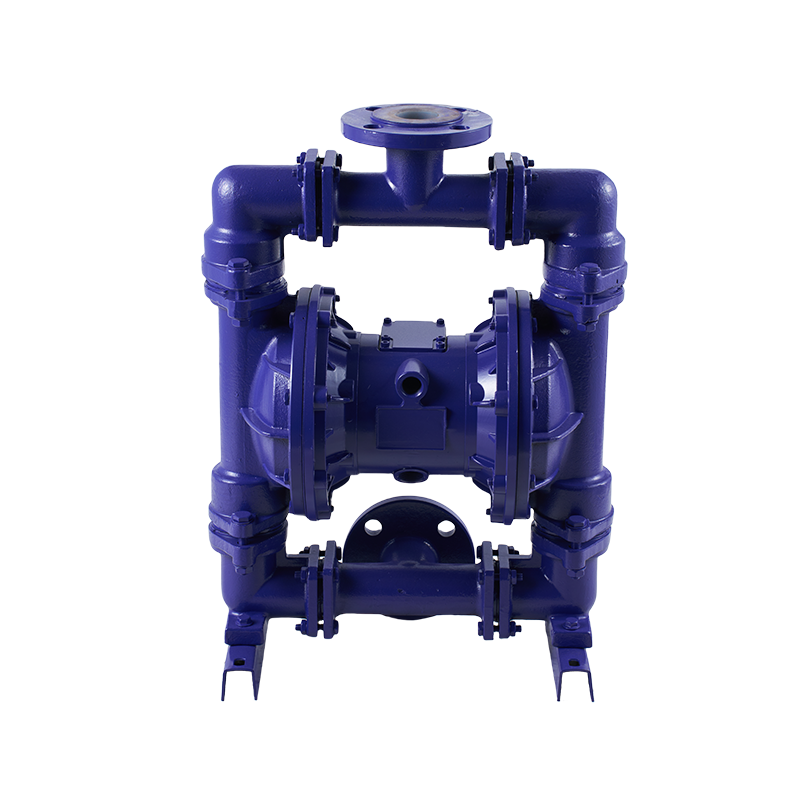

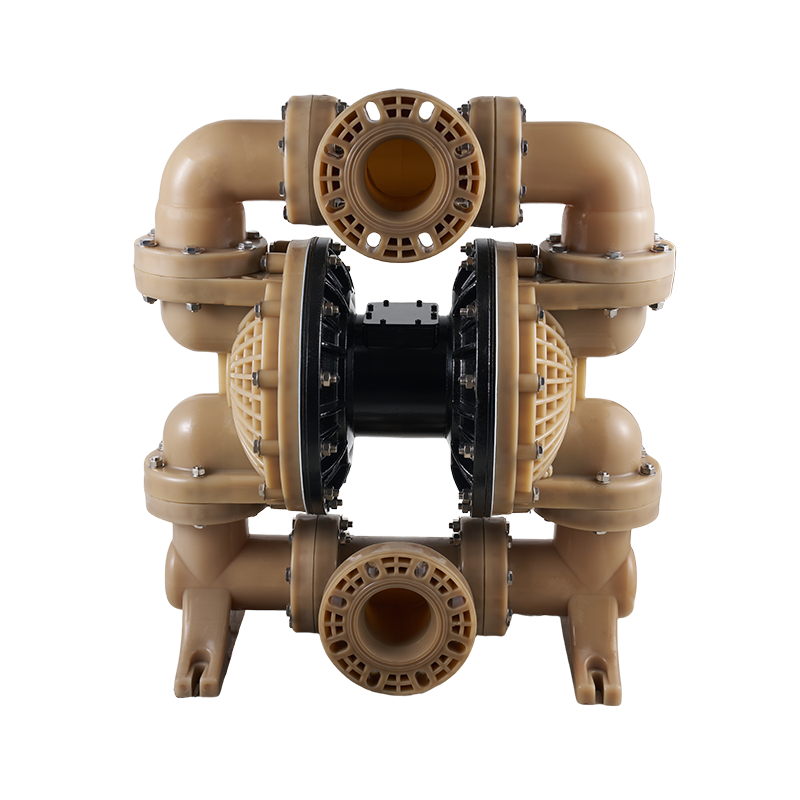

To begin with, the design of a Double Diaphragm Pump is inherently suited to handle thick and abrasive materials. Unlike centrifugal pumps, which rely on high-speed impellers that can wear out quickly when faced with abrasive mud, Double Diaphragm Pumps operate on a different principle. They use two flexible diaphragms that create a positive displacement action, ensuring that even the thickest and abrasive mud can be moved efficiently. This design eliminates the need for complex internal components that are prone to wear and tear, making the pump more durable and reliable in harsh environments.

One of the key features that makes Double Diaphragm Pumps stand out is their ability to self-prime. This means they can start operating even when the mud level is low, without the need for a separate priming mechanism. This is particularly important in applications where the mud is not always at a consistent level, such as in construction sites or mining operations. The self-priming capability ensures that the pump can operate continuously, reducing downtime and increasing overall efficiency.

Another advantage of Double Diaphragm Pumps is their ability to handle high-viscosity fluids. Thick mud can be challenging for many pumps, but the design of the Double Diaphragm Pump allows it to move these fluids with ease. The positive displacement action ensures that the mud is pushed through the pump without losing pressure, maintaining a consistent flow rate. This is essential in applications such as dredging, where the mud needs to be transported over long distances.

The durability of Double Diaphragm Pumps is another reason they are ideal for thick, abrasive mud applications. These pumps are often constructed with high-quality materials that can withstand the harsh conditions of handling abrasive materials. For instance, many Double Diaphragm Pumps are made from durable materials like cast iron or stainless steel, which are resistant to wear and corrosion. This ensures that the pump can operate for extended periods without significant degradation.

Moreover, Double Diaphragm Pumps are known for their low - maintenance requirements. Unlike other types of pumps that require frequent part replacements and extensive servicing, Double Diaphragm Pumps have fewer moving parts. This reduces the likelihood of mechanical failures and lowers maintenance costs. In industries where downtime can be costly, such as in construction or mining, the reliability of Double Diaphragm Pumps is a significant advantage.

One of the common applications for Double Diaphragm Pumps is in the construction industry, where they are used to handle thick, abrasive mud generated during excavation and drilling operations. These pumps are also widely used in the mining sector, where they are employed to transfer sludge and other abrasive materials. The ability of Double Diaphragm Pumps to handle high-solids content without clogging makes them ideal for these applications.

Another important feature of Double Diaphragm Pumps is their ability to run dry without damage. This is a significant advantage in environments where the mud supply may be intermittent. Unlike other pumps that can be damaged if they run dry, Double Diaphragm Pumps can operate safely without the risk of mechanical failure. This ensures that the pump can be used in a variety of settings without the need for constant monitoring.

In addition to their durability and low - maintenance requirements, Double Diaphragm Pumps are also energy-efficient. They operate on compressed air, which means they use less energy compared to electric or diesel-powered pumps. This not only reduces operating costs but also makes them more environmentally friendly. In an era where sustainability is a key concern, the energy efficiency of Double Diaphragm Pumps is a major selling point.

The versatility of Double Diaphragm Pumps is another reason they are so popular in thick, abrasive mud applications. They can be easily configured to handle different flow rates and pressures, making them suitable for a wide range of tasks. Whether you need to transfer a small amount of mud or a large volume, Double Diaphragm Pumps can be adjusted to meet your specific needs. This adaptability makes them an ideal choice for industries that require flexibility in their pumping operations.

Double Diaphragm Pumps are the ideal solution for handling thick, abrasive mud applications. Their self-priming capability, ability to handle high-viscosity fluids, durability, low - maintenance requirements, and energy - efficiency make them a choice compared to traditional pumps. Whether you are in the construction, mining, or dredging industry, the reliability and versatility of Double Diaphragm Pumps ensure that your operations run smoothly and efficiently. As industries continue to face more challenging materials and environments, the Double Diaphragm Pump stands out as a reliable and efficient solution.

English

English русский

русский Español

Español عربى

عربى