What Factors Should Guide Your Diaphragm Pump Selection?

2026.02.06

2026.02.06

Industry News

Industry News

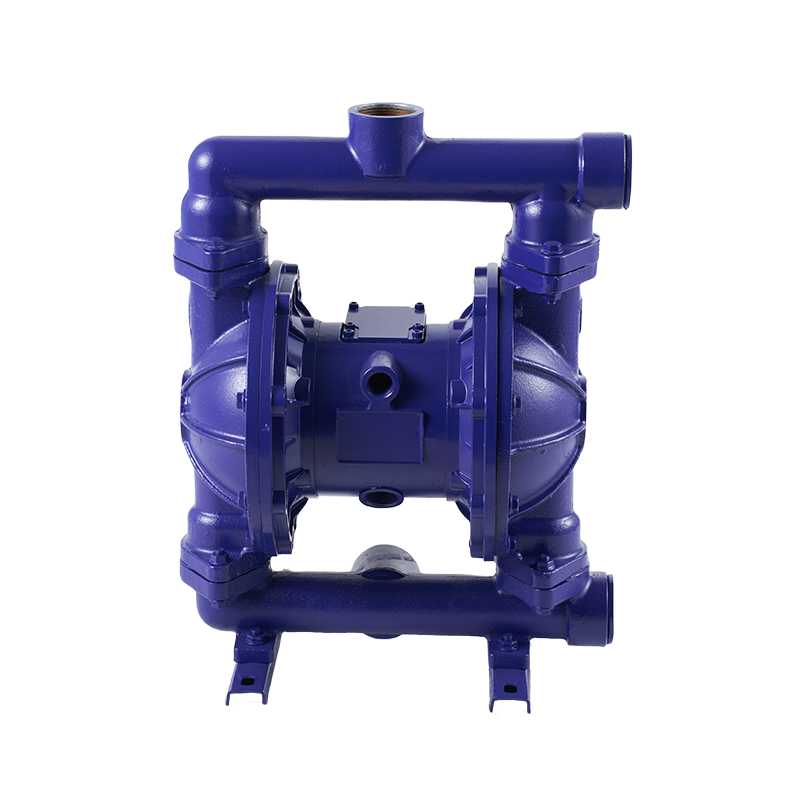

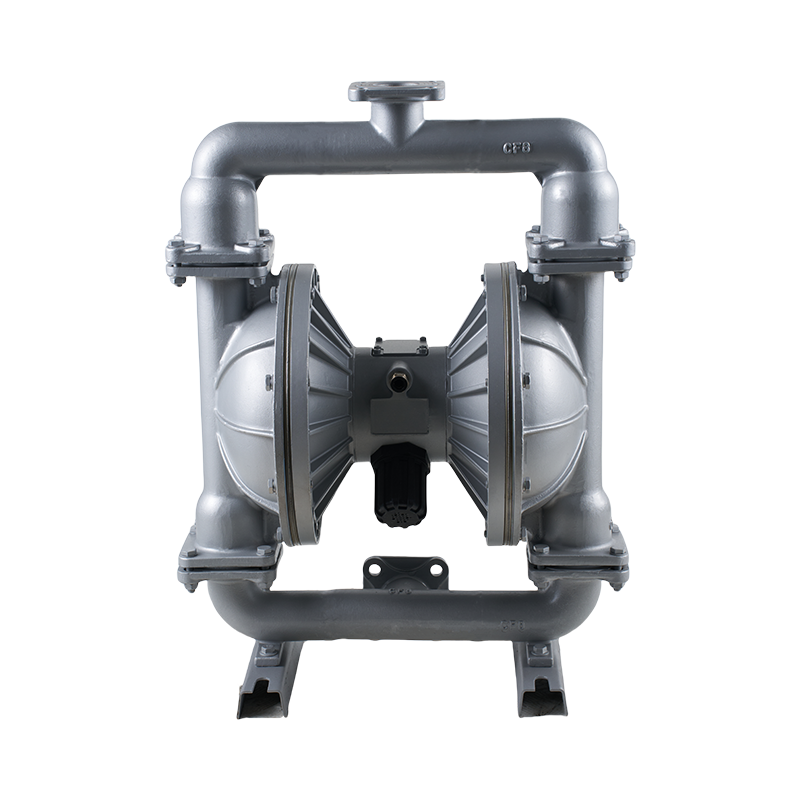

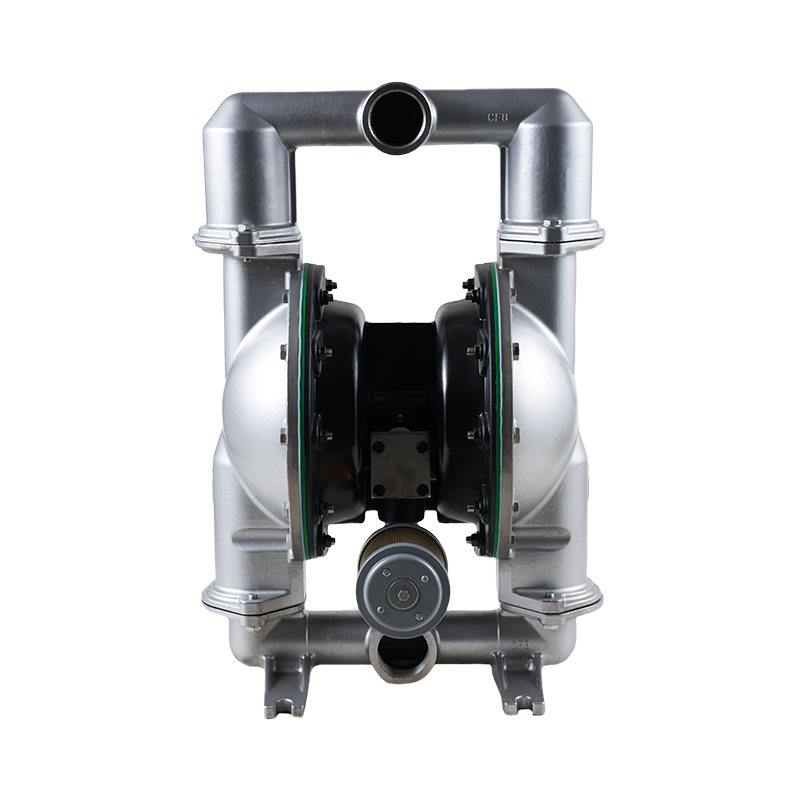

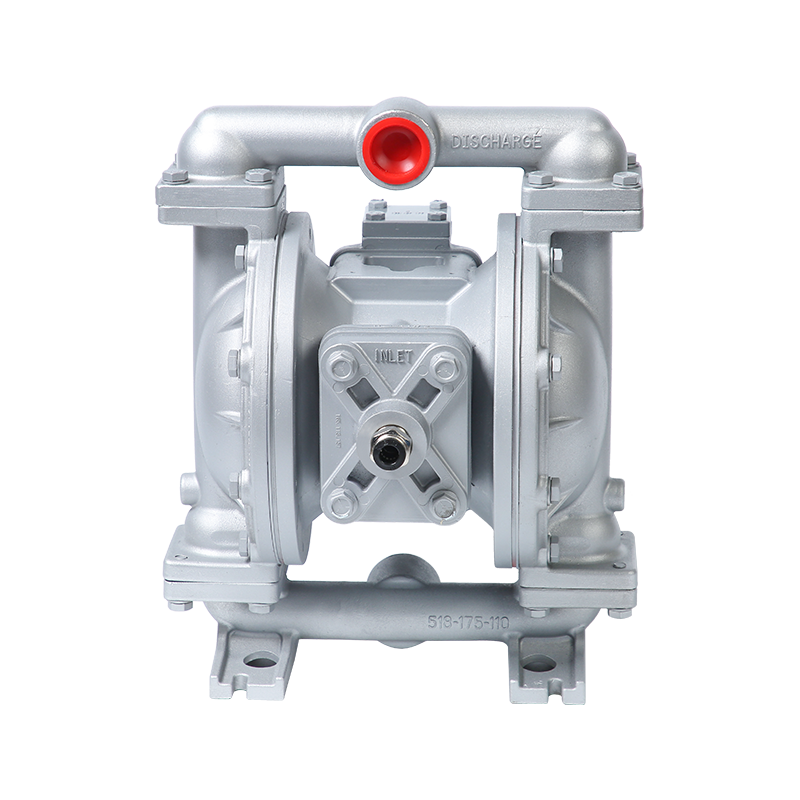

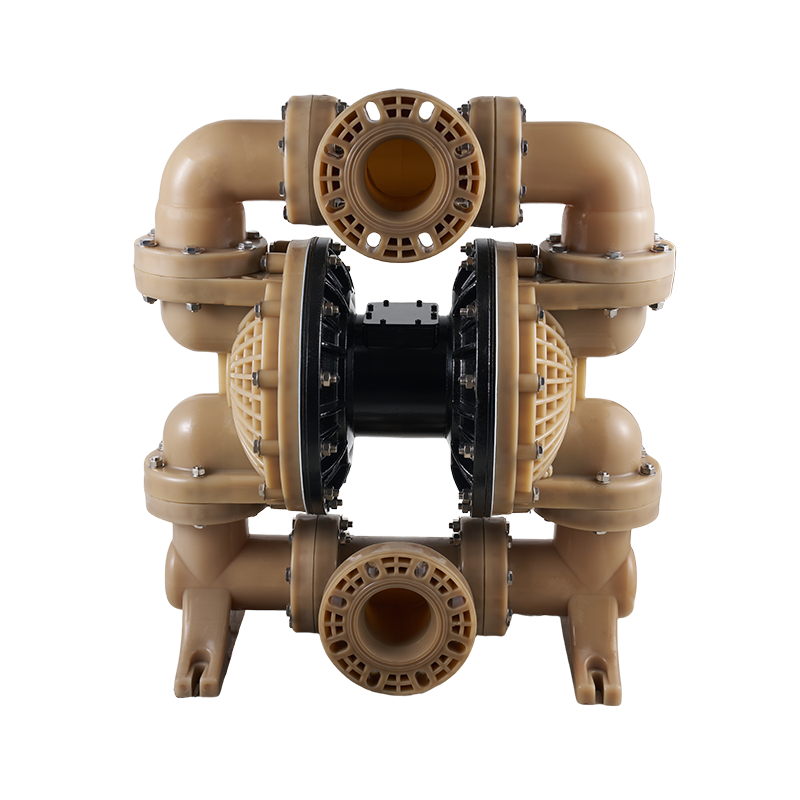

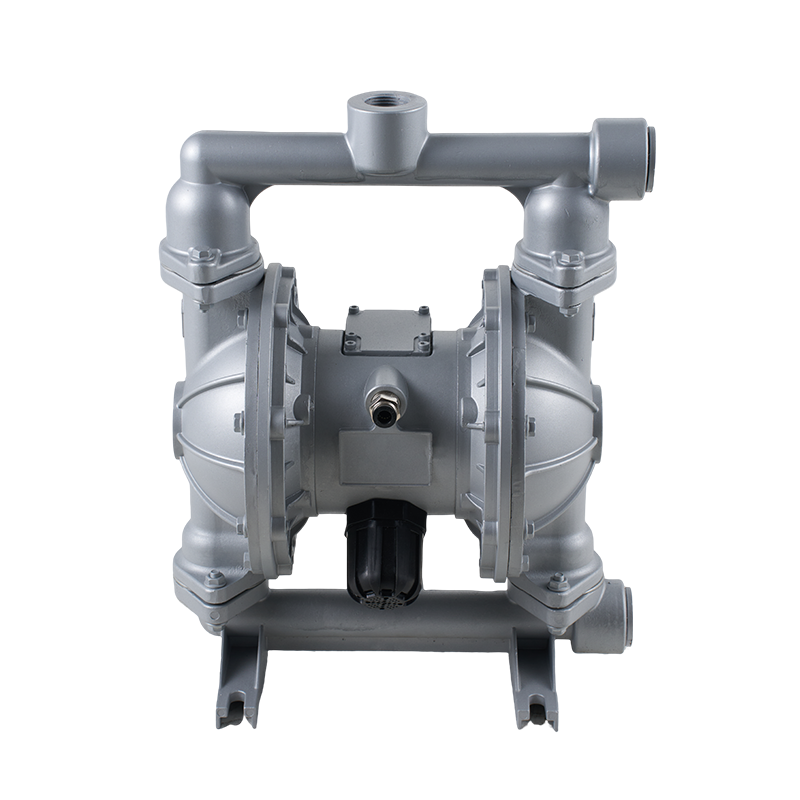

Choosing the right diaphragm pump can be challenging if you aren't familiar with industrial pump applications. Diaphragm pumps are versatile machines designed to move liquids efficiently, including viscous, corrosive, or abrasive fluids. They are widely used in chemical processing, food production, wastewater treatment, and other industrial applications where reliability and precision are critical. Working with a Diaphragm Pump Factory can simplify the selection process by offering detailed product knowledge, customization options, and proven manufacturing standards.

Advantages of Purchasing from a Diaphragm Pump Factory

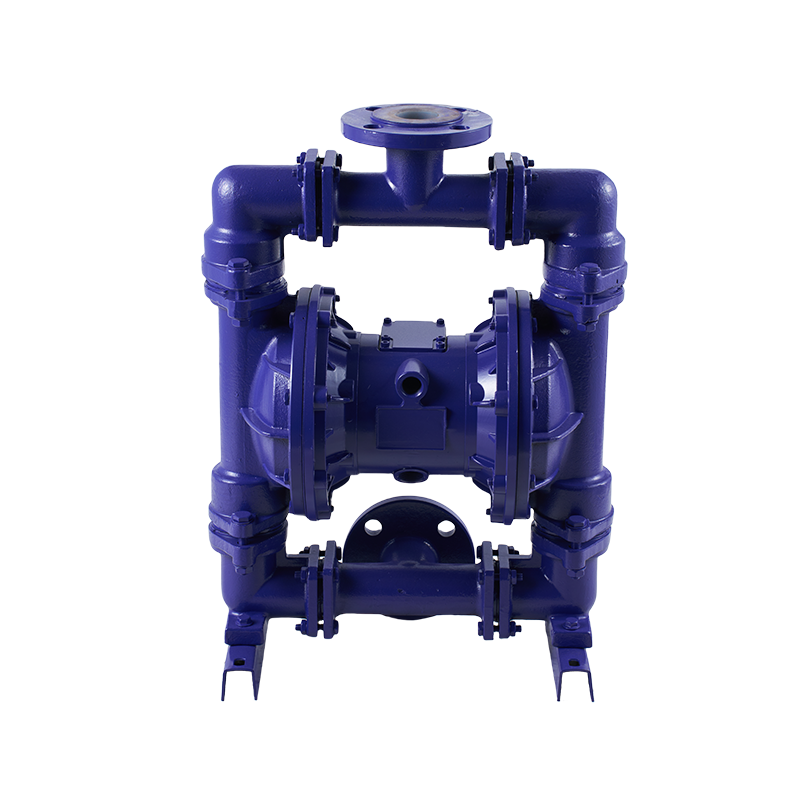

Partnering with a Diaphragm Pump Factory offers several advantages for industrial buyers. Early, these factories specialized in producing pumps that meet international quality standards, ensuring long-term durability. Second, they typically provide a variety of pump types, including standard diaphragm pumps and double diaphragm pumps. This range allows buyers to select a model that fits fluid type, pressure requirements, and environmental conditions.

China-based Diaphragm Pump Factory can often provide competitive pricing without compromising on performance. Great manufacturing processes and skilled technicians contribute to the efficiency and reliability of each pump. Buyers also benefit from faster production timelines and access to technical support, which can be critical for industrial operations that cannot afford downtime.

Understanding Different Types of Diaphragm Pumps

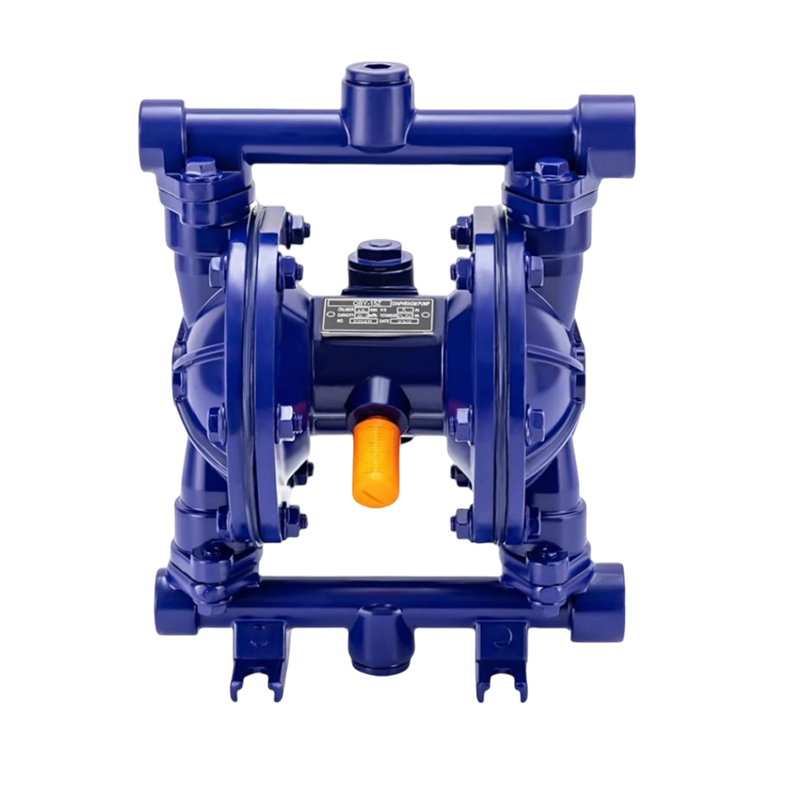

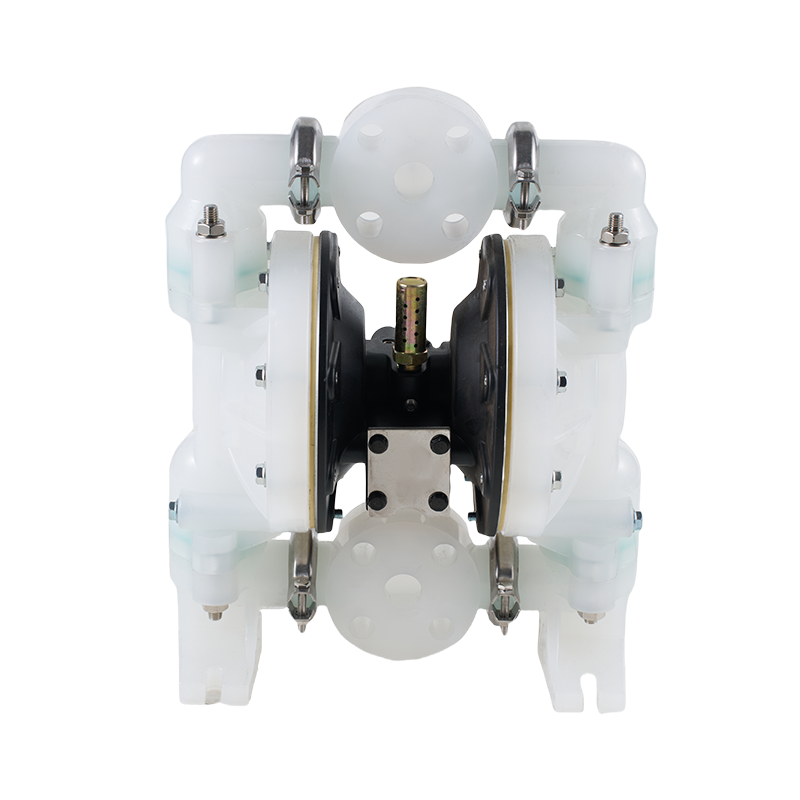

There are several types of diaphragm pumps, each suited for different industrial needs. Standard diaphragm pumps are ideal for clean fluids or liquids with low solid content. They are commonly used where a gentle pumping action is required to prevent damage to the fluid or system. Double diaphragm pumps, on the other hand, are designed to handle more aggressive applications. They can manage viscous, abrasive, or corrosive liquids with minimal wear and tear.

Choosing the right type requires understanding both the fluid properties and operational demands. A Diaphragm Pump Factory can guide you in evaluating flow rate, pressure, and chemical compatibility to ensure the pump performs efficiently over its service life.

Customization and Technical Support

Many Diaphragm Pump Factories offer customization options. Pumps can be built using materials resistant to corrosion or abrasion, depending on the application. Customization may also include specific flow capacities, connection types, or even modifications to the pump chamber design.

In addition to product customization, a reputable Diaphragm Pump Factory provides technical support. This assistance can include installation guidance, troubleshooting tips, and maintenance advice, helping industrial users avoid costly downtime. Working directly with a factory ensures that you are not just purchasing a pump, but gaining a long-term solution tailored to your needs.

Choosing a Factory for Bulk or Specialized Orders

When sourcing pumps in larger quantities or for specialized applications, selecting a reliable Diaphragm Pump Factory becomes even more critical. Factories in China are known for producing pumps at scale while maintaining quality standards. They also provide access to double diaphragm pump models that handle harsh industrial environments. Competitive pricing combined with technical support and customization options makes these factories an attractive option for global buyers.

A well-chosen diaphragm pump can improve efficiency, reliability, and safety in industrial operations. By working with a Diaphragm Pump Factory, buyers gain access to a wide range of pumps, technical expertise, and customization options. Whether you need standard or double diaphragm pumps, understanding your operational requirements and consulting a specialized factory ensures you select the right solution.

English

English русский

русский Español

Español عربى

عربى