Why Pneumatic Diaphragm Pumps Outlast Electric Competitors?

2025.08.17

2025.08.17

Industry News

Industry News

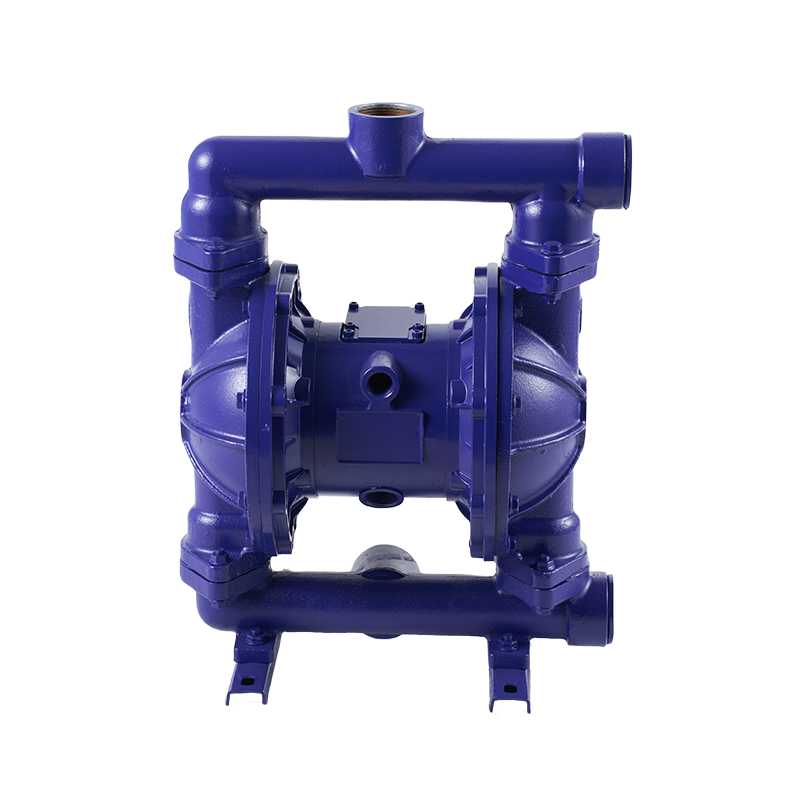

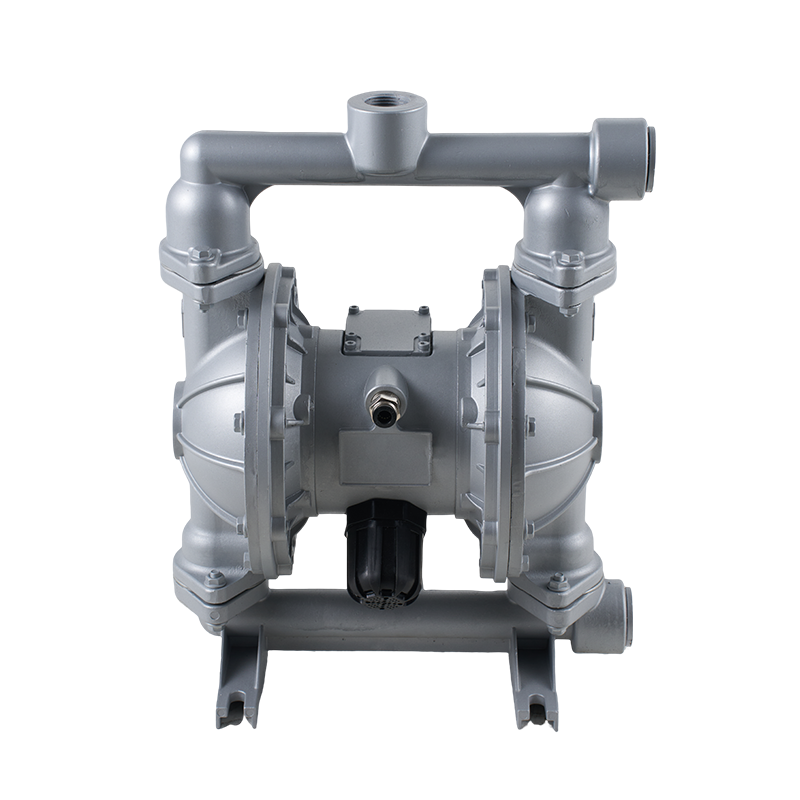

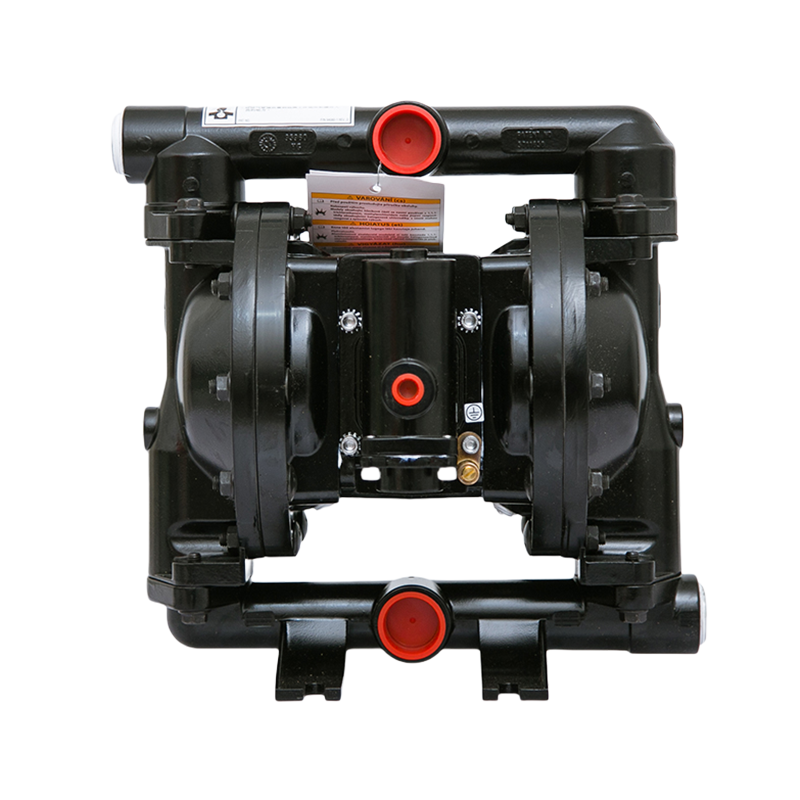

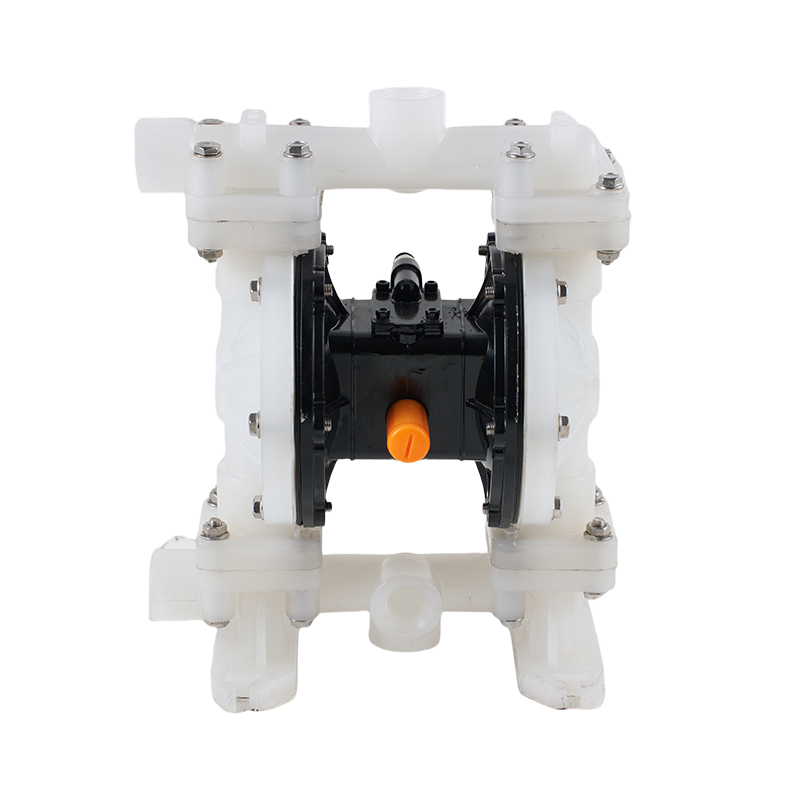

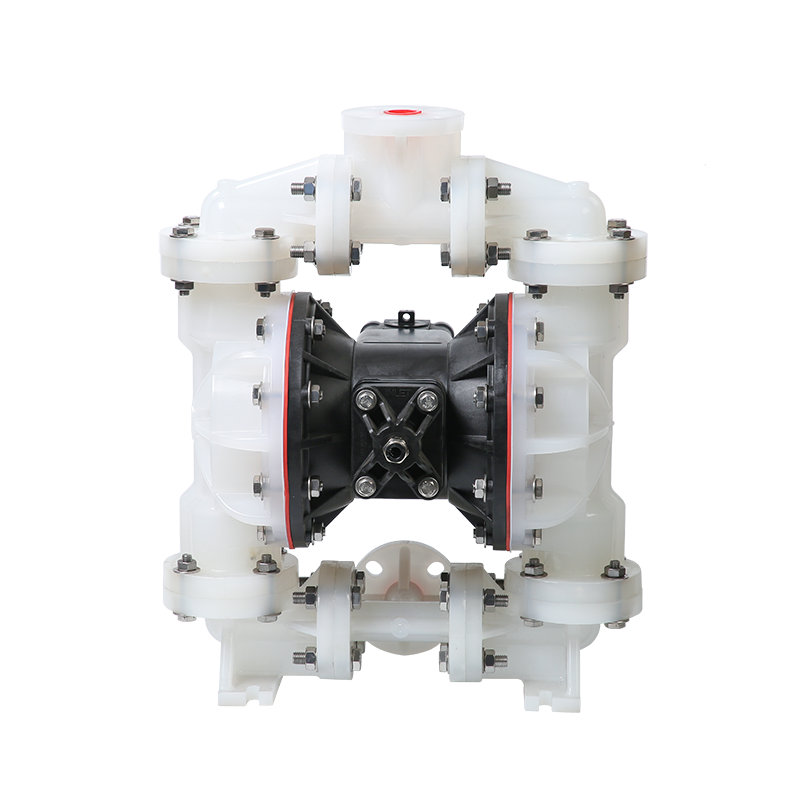

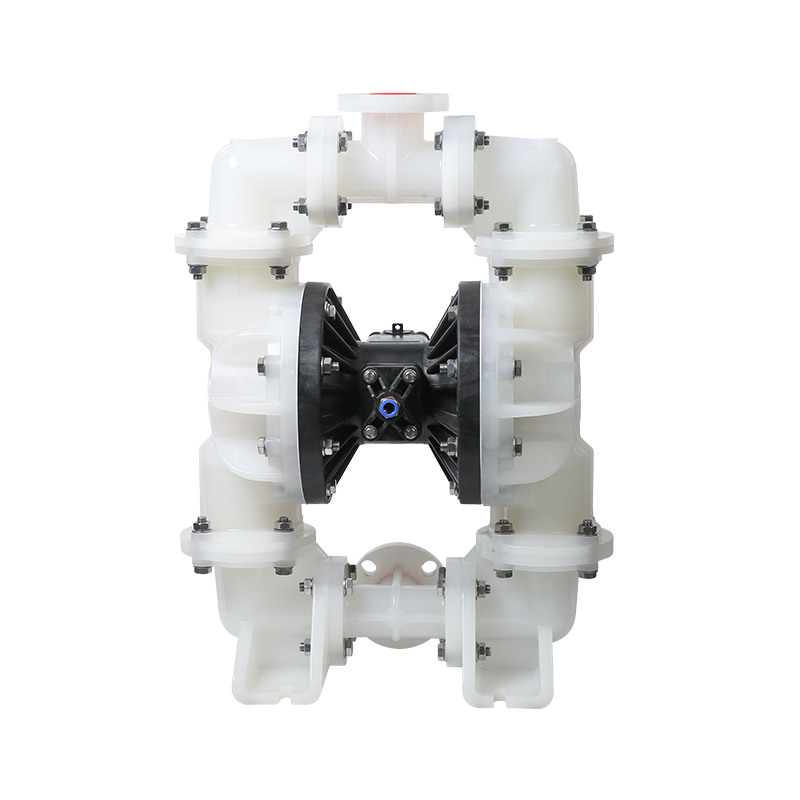

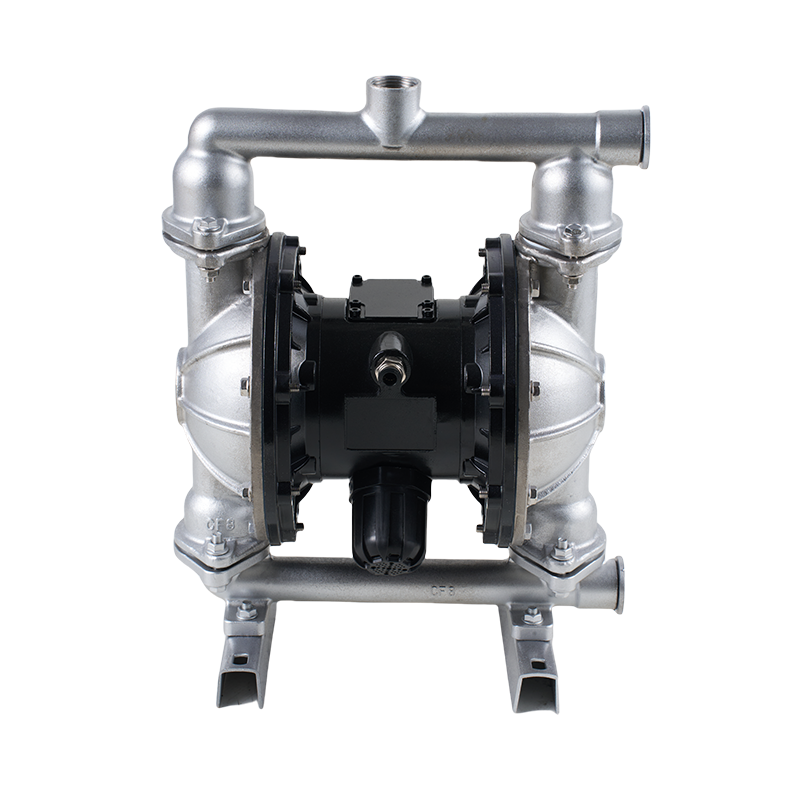

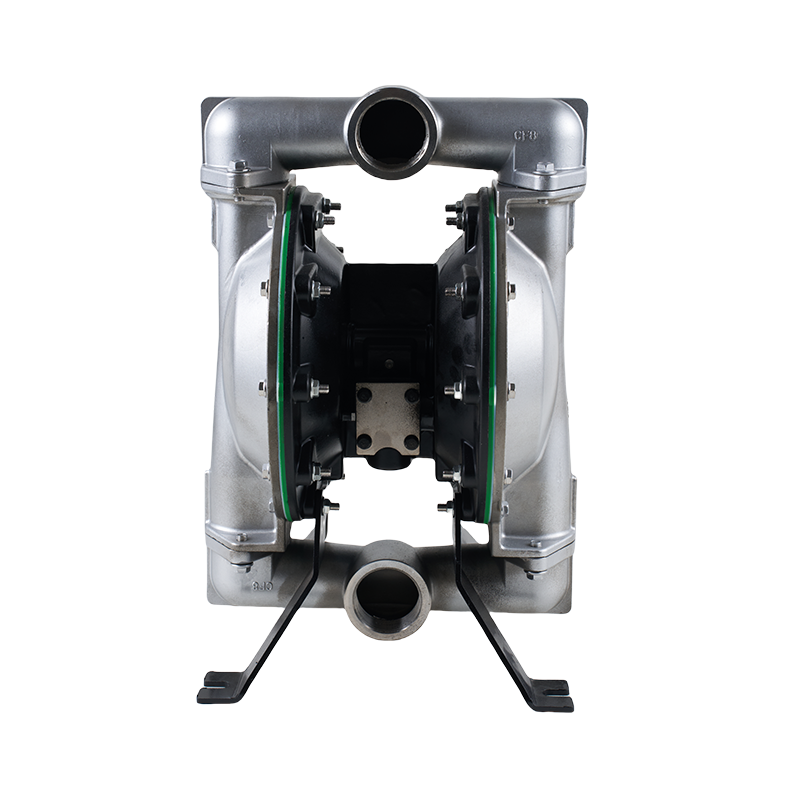

In industries where durability, reliability, and versatility are vital, choosing the right pump can make a significant difference in operational efficiency. While electric pumps are common, many operators are turning to Pneumatic Diaphragm technology for its proven longevity. Whether in manufacturing, wastewater treatment, or chemical handling, the advantages of air-powered pumps—particularly the Small Air Diaphragm Pump and Small Air Operated Diaphragm Pump—are becoming increasingly clear.

The Durability Factor

A Pneumatic Diaphragm pump operates using compressed air to move flexible diaphragms, creating suction and discharge without relying on electric motors. This design eliminates many wear-prone components found in electric pumps, such as bearings, seals, and brushes. For example, a Small Air Diaphragm Pump can operate for long periods without overheating or suffering electrical faults, which can be common in motor-driven systems.

The Small Air Operated Diaphragm Pump shares the same air-powered principle, providing consistent performance even in challenging conditions. Because there are no electric coils or wiring, these pumps can function safely in damp, dusty, or hazardous environments where electric pumps might fail. This lack of electrical components also reduces the need for complex maintenance, contributing to their extended lifespan.

Performance in Harsh Environments

Industries such as mining, construction, and oil refining often require equipment that can withstand abrasive materials, fluctuating temperatures, and variable pressures. A Pneumatic Diaphragm pump meets these demands effectively. It is capable of handling viscous liquids, slurries, and even fluids containing small solids without losing performance.

A Small Air Diaphragm Pump is particularly valued in mobile and temporary setups due to its lightweight build and portability. Operators can quickly deploy these pumps on job sites, connect them to an air supply, and begin transferring liquids without extensive setup procedures. The Small Air Operated Diaphragm Pump, with its compact form and durable materials, is equally effective for continuous duty in industrial plants where uptime is a priority.

Safety Advantages Over Electric Pumps

Another reason Pneumatic Diaphragm pumps outlast their electric counterparts is their inherent safety in hazardous locations. Without electrical sparks or high heat generation, they can operate in explosive or flammable atmospheres with reduced risk. A Small Air Diaphragm Pump can also be stalled without damage, meaning that if discharge lines become blocked, the pump simply stops until the blockage is cleared—something electric pumps may not handle without damage.

Similarly, the Small Air Operated Diaphragm Pump benefits from this stall-resistant feature, allowing operators to focus on process control without worrying about burnout or overheating. This capability translates into fewer repairs, lower replacement costs, and longer operational life.

Cost Efficiency Through Reduced Maintenance

A major factor in pump longevity is the total maintenance required over its service life. Electric pumps often require routine replacement of seals, lubrication of moving parts, and inspections for electrical safety. In contrast, a Pneumatic Diaphragm pump requires minimal attention beyond diaphragm inspection and occasional cleaning. The simplicity of the design means fewer parts to wear out.

For small-scale operations, a Small Air Diaphragm Pump offers a return on investment. It delivers consistent output with minimal downtime, making it a preferred choice for workshops, small factories, and portable equipment setups. In larger industrial facilities, the Small Air Operated Diaphragm Pump can be integrated into automated systems for continuous duty without the same maintenance burdens that electric pumps impose.

Wide Industry Adoption

From paint manufacturing to food processing, the Pneumatic Diaphragm design is gaining ground as a dependable alternative to electric systems. The Small Air Diaphragm Pump is frequently used in laboratory and pilot plant applications, where precise handling and portability are essential. The Small Air Operated Diaphragm Pump finds its place in more demanding production environments, proving that compact pumps can still deliver industrial-grade reliability.

When considering operational lifespan, safety, and ease of maintenance, the Pneumatic Diaphragm pump stands out as achoice. Whether it is a lightweight Small Air Diaphragm Pump for portable use or a robust Small Air Operated Diaphragm Pump for industrial duty, these air-powered systems offer lasting value. Their ability to function in harsh environments, handle diverse liquids, and operate without complex maintenance explains why they consistently outlast electric competitors across a wide range of industries.

English

English русский

русский Español

Español عربى

عربى