Aluminum Alloy Diaphragm Pump Industry Knowledge

1. What are the key advantages of using an Aluminum Alloy Diaphragm Pump in industrial applications?

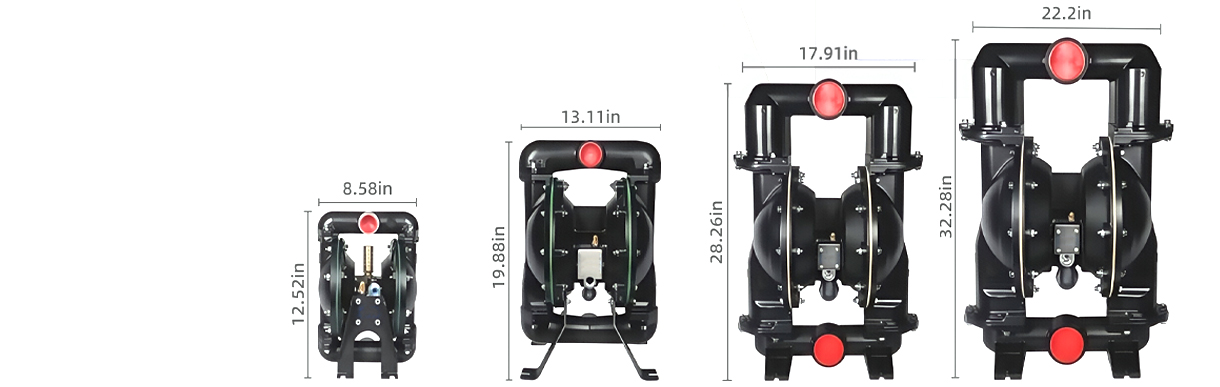

An Aluminum Alloy Diaphragm Pump offers several critical advantages that make it a preferred choice in many industrial settings. Due to the lightweight yet durable nature of aluminum alloy, these pumps provide corrosion resistance while maintaining mechanical strength. Compared to traditional materials, the Aluminum Pump design reduces overall weight, which simplifies installation and lowers transportation costs.

Additionally, the aluminum alloy construction allows for better heat dissipation, which extends the service life of the Aluminum Alloy Pneumatic Diaphragm Pump. This heat resistance is crucial in pneumatic applications where the pump can experience rapid cycles of pressurization. The diaphragm pump's design also minimizes maintenance needs because the aluminum alloy resists wear and corrosion from harsh chemicals, making it suitable for transferring solvents, acids, and other aggressive fluids.

In summary, an Aluminum Alloy Diaphragm Pump combines lightweight design, corrosion resistance, durability, and efficient thermal performance, making it highly advantageous for industries that demand reliable and long-lasting pumping solutions.

2. How does a China Aluminum Alloy Pneumatic Diaphragm Pump Manufacturer ensure high-quality and reliability in their products?

A reputable China Aluminum Alloy Pneumatic Diaphragm Pump Manufacturer focuses heavily on quality control and advanced manufacturing techniques to produce top-grade Aluminum Alloy Diaphragm Pumps. The manufacturer sources high-quality aluminum alloys that meet strict international standards, ensuring the base material of the Aluminum Pump is robust and corrosion-resistant.

During production, precision casting and CNC machining technologies are employed to maintain tight tolerances, critical for the pump's diaphragm sealing and overall airtightness. The pneumatic components, including valves and diaphragms, undergo rigorous testing to guarantee compatibility and durability under different operating pressures.

Moreover, the China Aluminum Alloy Pneumatic Diaphragm Pump Manufacturer invests in extensive performance testing—such as pressure endurance, flow rate verification, and chemical resistance tests—to certify that each Aluminum Alloy Pneumatic Diaphragm Pump can operate reliably in its intended environment. Manufacturers often provide customization services to tailor Aluminum Pumps to specific industrial needs, enhancing their versatility and performance.

Finally, continuous innovation and customer feedback integration enable these manufacturers to improve product longevity and efficiency consistently, maintaining a strong reputation in both domestic and international markets.

3. In what industries is the Aluminum Alloy Pneumatic Diaphragm Pump commonly used, and why is the Aluminum Pump design preferred?

The Aluminum Alloy Pneumatic Diaphragm Pump is widely used across several industries due to its versatile features and robust performance. Key sectors include chemical processing, pharmaceuticals, food and beverage, water treatment, and petroleum. The chemical industry relies heavily on Aluminum Alloy Diaphragm Pumps because these pumps handle corrosive liquids and abrasive slurries efficiently, thanks to the corrosion resistance of aluminum alloy.

In the pharmaceutical and food industries, the Aluminum Pump's non-reactive surface and ease of cleaning make it ideal for hygienic applications. Pneumatic operation ensures the pumps can function safely in explosive or flammable environments, common in oil and gas sectors.

Water treatment plants use Aluminum Alloy Pneumatic Diaphragm Pumps for dosing chemicals and transferring sludge because of their durability and reliability. The lightweight aluminum design reduces fatigue during frequent maintenance and lowers operational costs.

The preference for an Aluminum Alloy Diaphragm Pump in these industries stems from the balance between strength, corrosion resistance, and weight. Compared to steel or plastic pumps, aluminum offer sheat dissipation and mechanical properties without adding unnecessary bulk. This makes the Aluminum Pump a choice for industries requiring durable, efficient, and lightweight pumping solutions.

English

English русский

русский Español

Español عربى

عربى