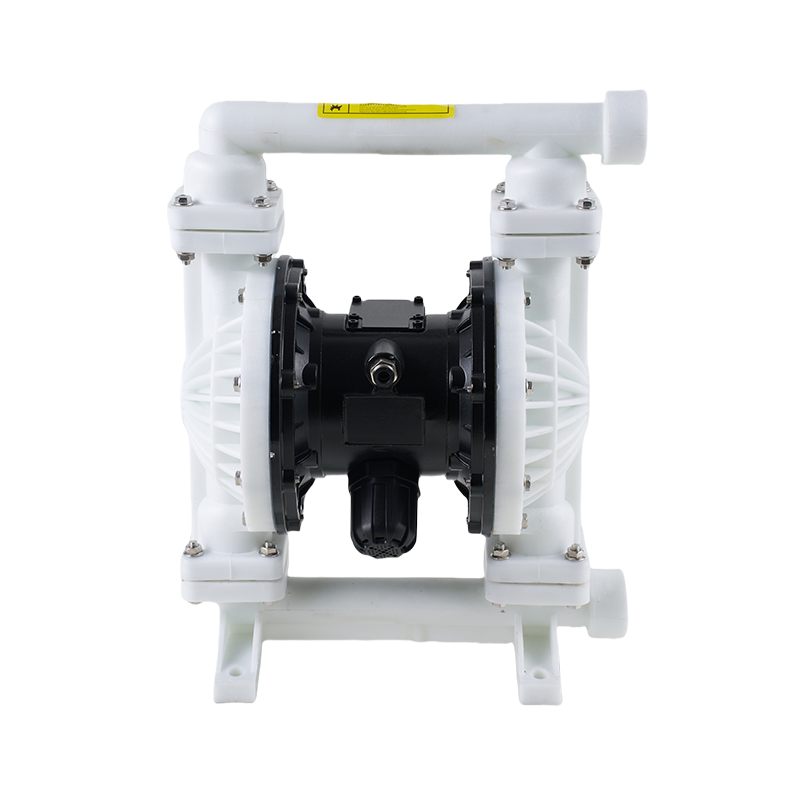

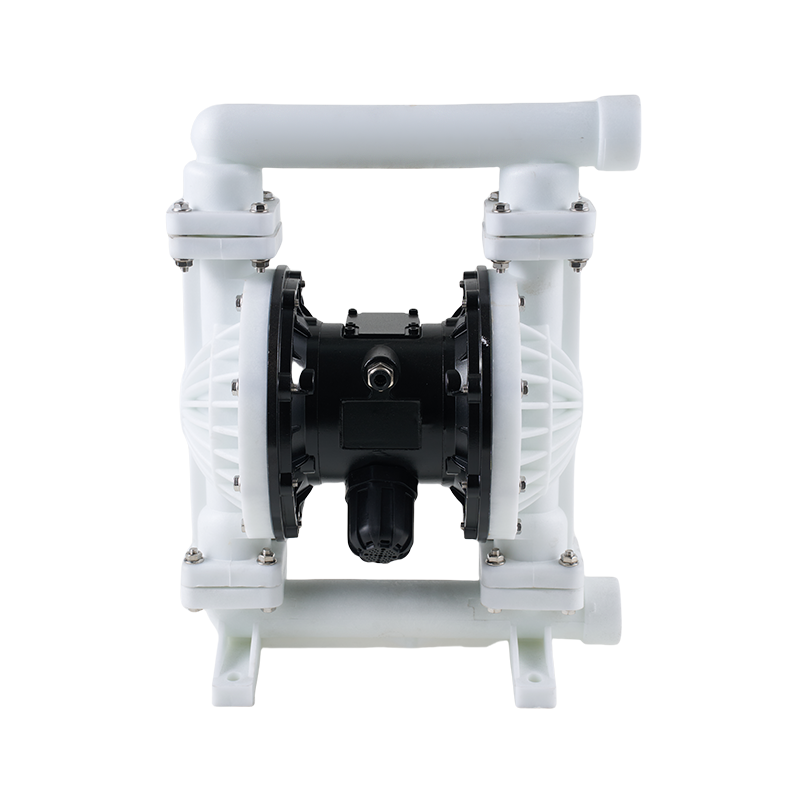

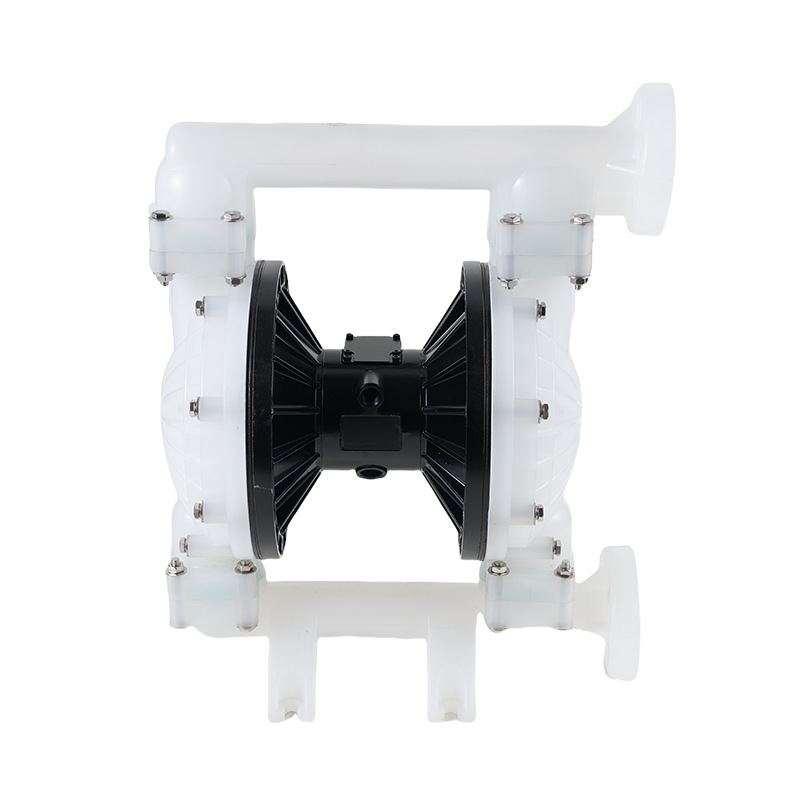

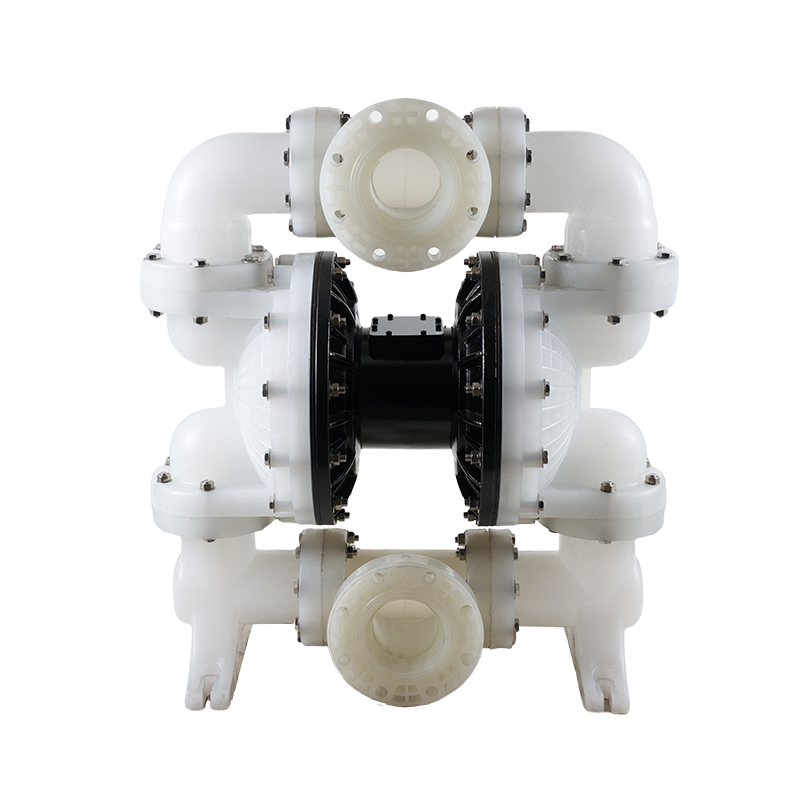

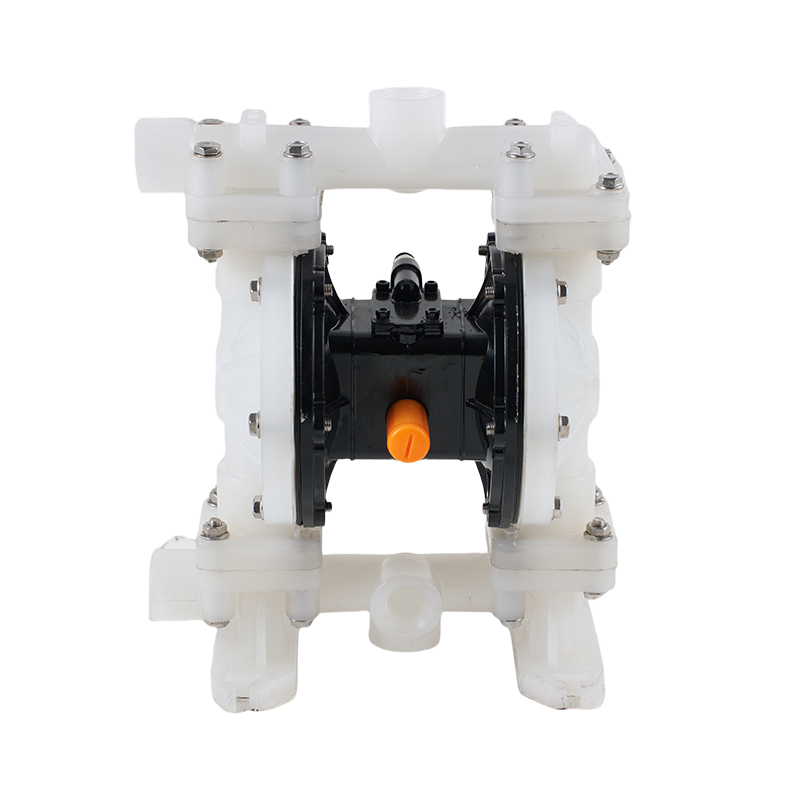

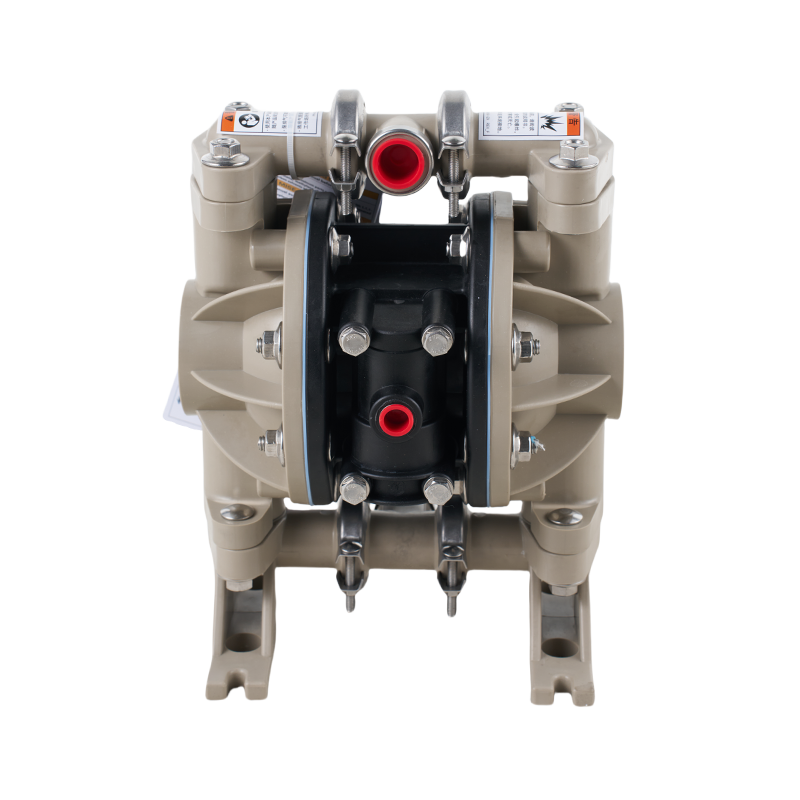

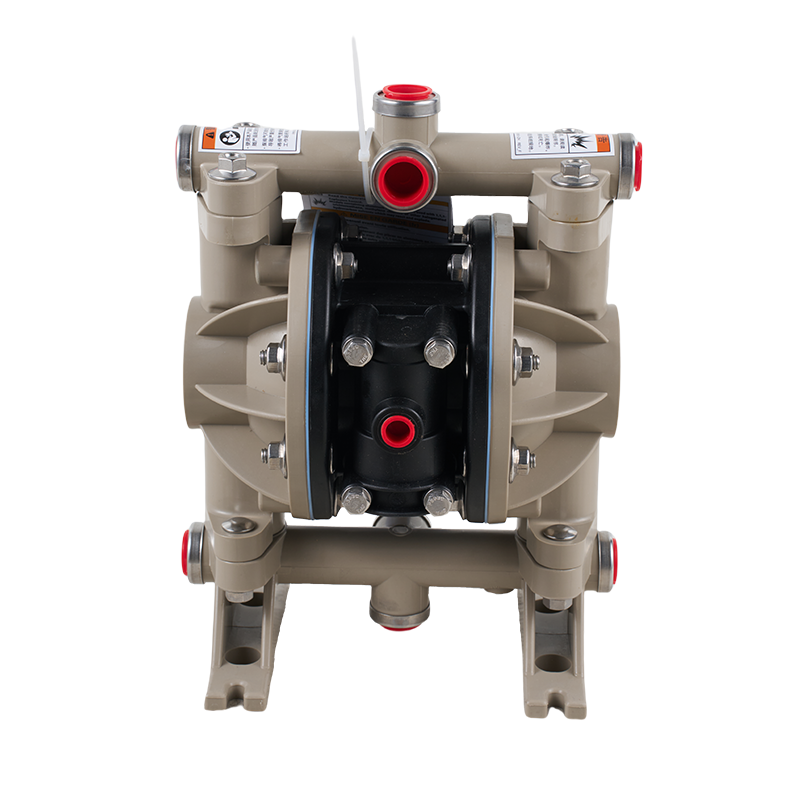

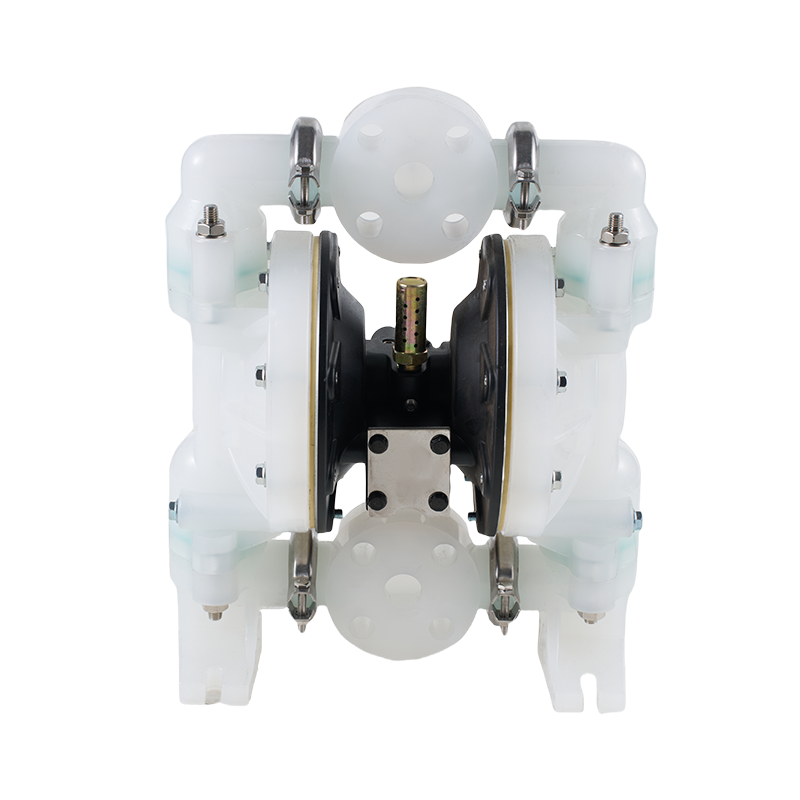

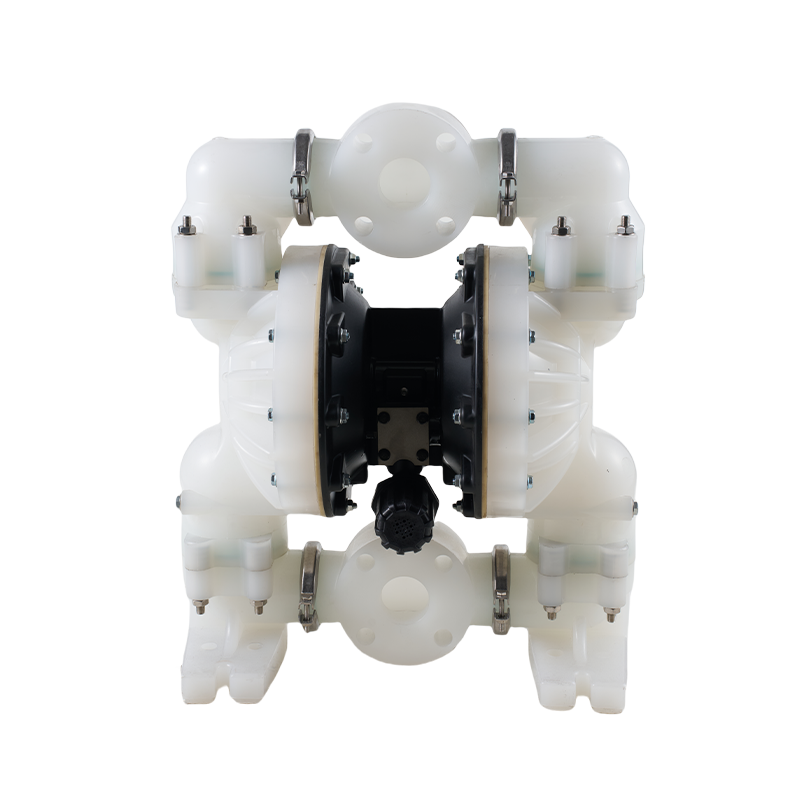

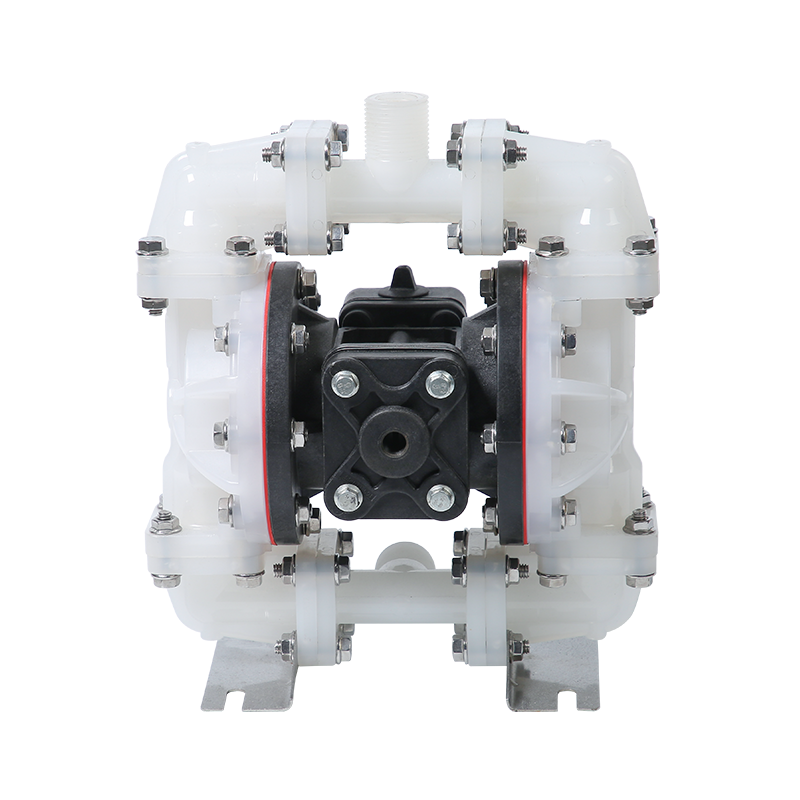

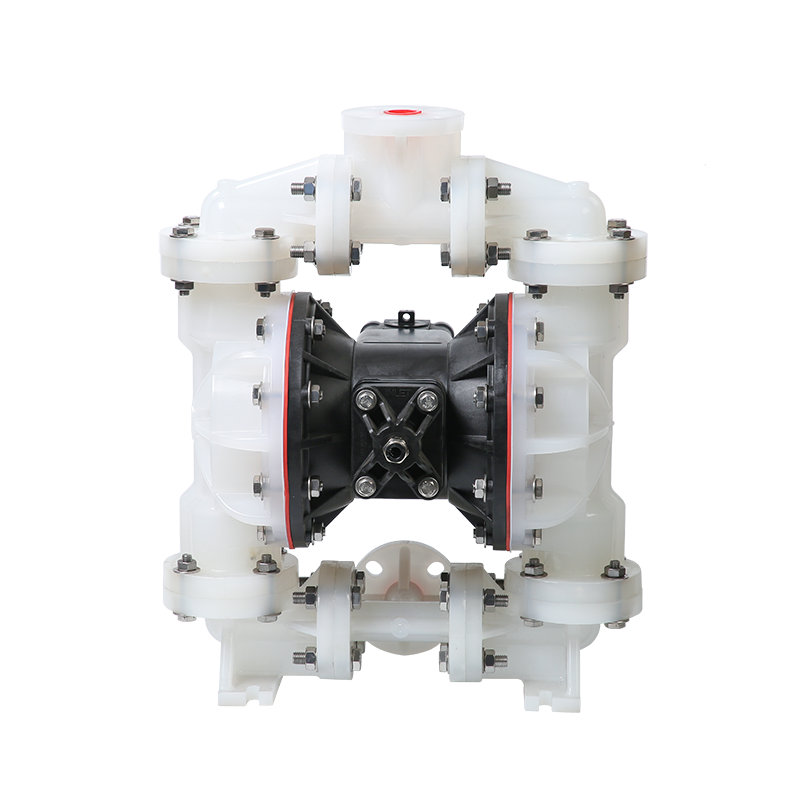

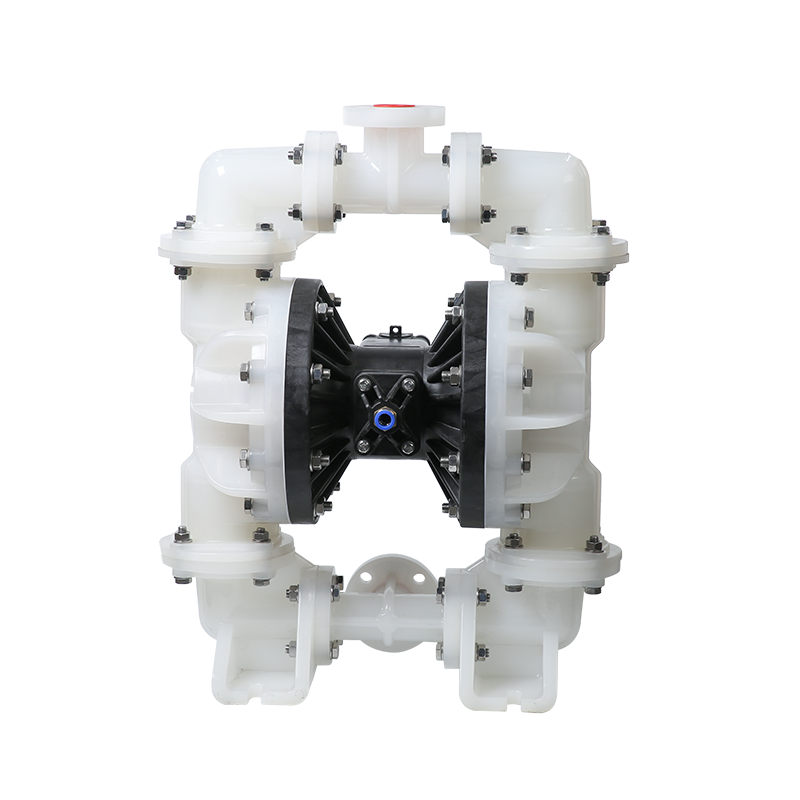

Zhejiang Zhanbo Diaphragm Pump Manufacturing Co., Ltd. is a professional China Polypropylene Diaphragm Pump manufacturer and OEM/ODM Polypropylene Diaphragm Pump factory integrating R&D, production, sales and service. The company's founding process can be traced back to 1989. It has always focused on the field of diaphragm pumps. It is the main drafting unit of the pneumatic diaphragm pump specification and an expert in diaphragm pumps.

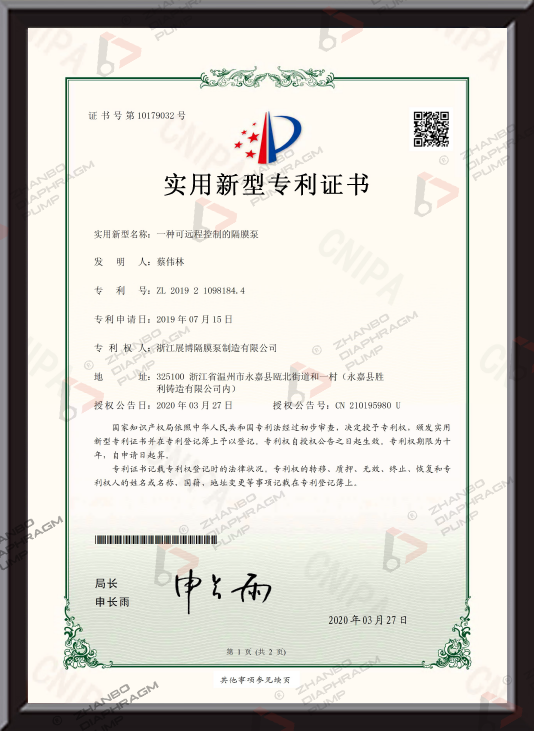

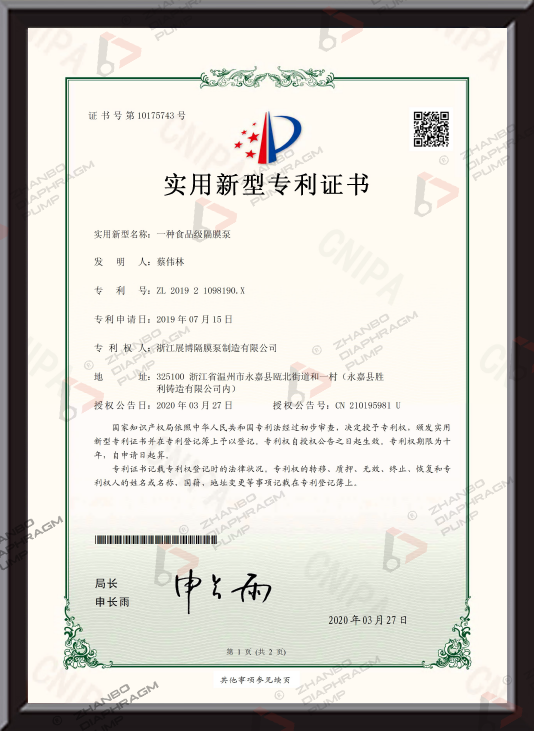

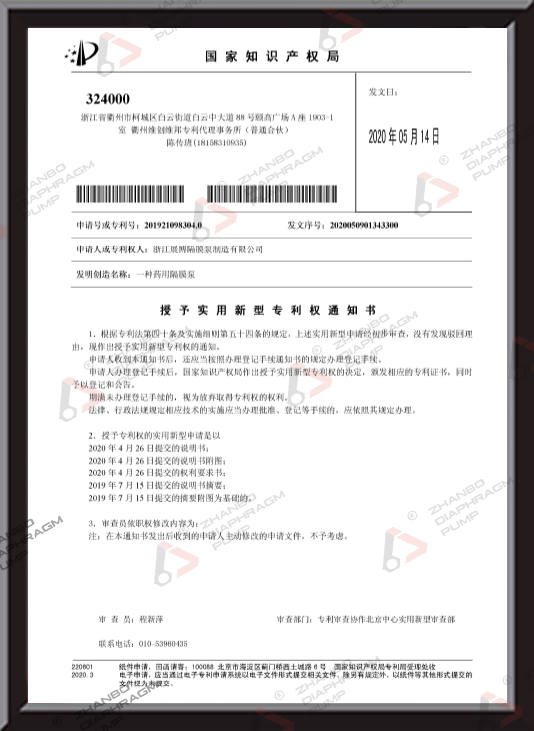

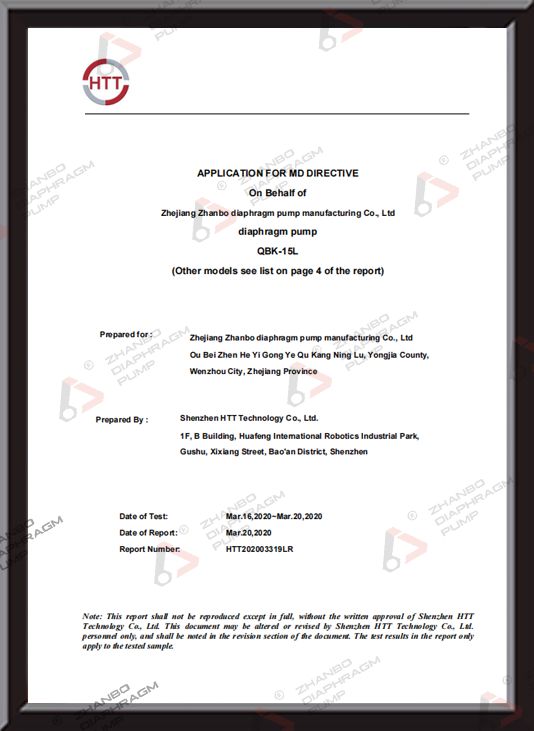

The company has successively obtained the national "high-tech" enterprise certification and the EU CE certification. So far, it has obtained many patents and passed the ISO9001 international quality system certification. It is a demonstration enterprise for scientific and technological innovation and achievement transformation.

The company also has a complete integrated service system: pre-sales technicians answer various technical inquiries, provide one-stop service suggestions according to customer needs, select suitable products for you, and determine reasonable solutions and quotations based on the above information and product quality, delivery cycle, etc. After-sales services include product installation, use, maintenance, troubleshooting, etc. We will continue to work hard to provide you with good products and services.

The company adheres to the business philosophy of "three specializations", "single-minded, professional, and focused". Based on implementing comprehensive quality management, it uses sophisticated process equipment and "excellent internal quality and similar appearance quality of handicrafts" to create a user-first service awareness to meet customer needs. The company has won wide praise from domestic and foreign customers for its high-quality and thoughtful after-sales service. Its products are sold to more than 30 provinces and cities across the country and the United States, Europe, Singapore, Myanmar, Australia, Africa, Vietnam, and other foreign markets.

Industrial operations often require pumping solutions that are both efficient and cost-conscious. A Cheap Diaphragm Pump offers a practical ...

READ MORE

English

English русский

русский Español

Español عربى

عربى