When to Select Rubber Diaphragm Pumps with Teflon Liners?

2025.08.18

2025.08.18

Industry News

Industry News

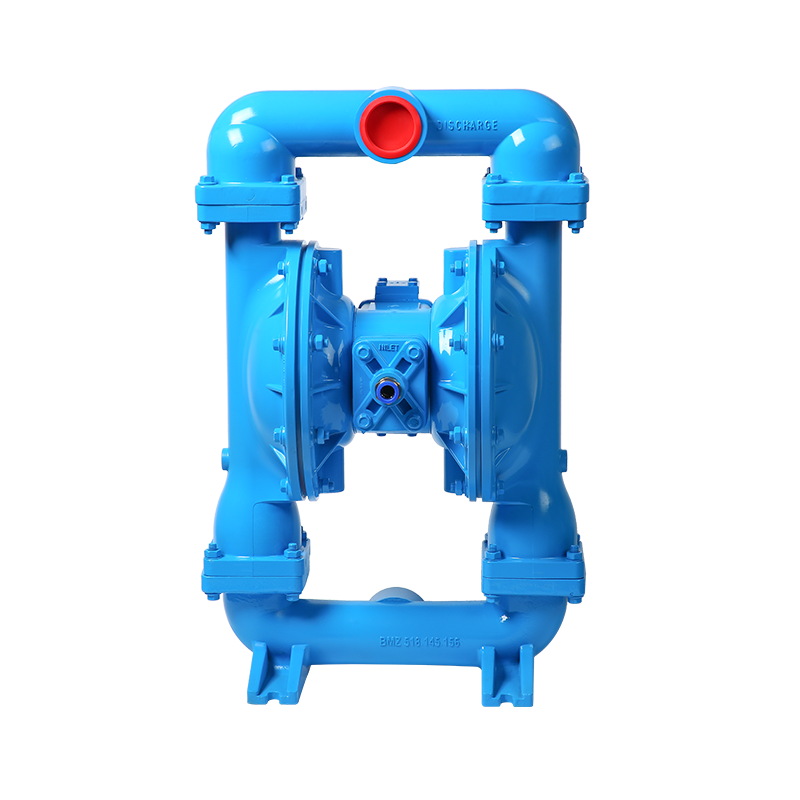

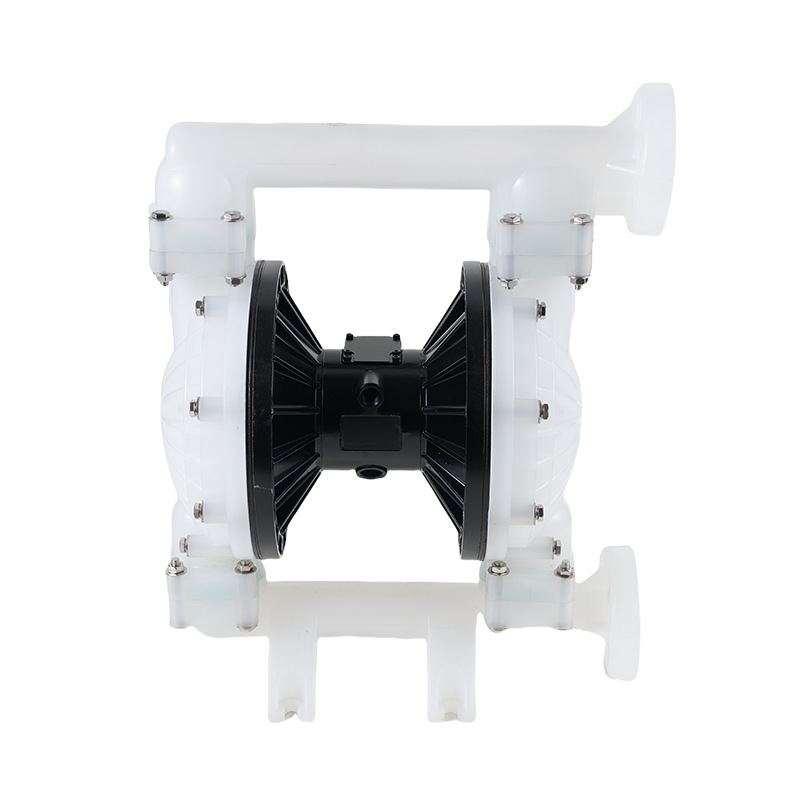

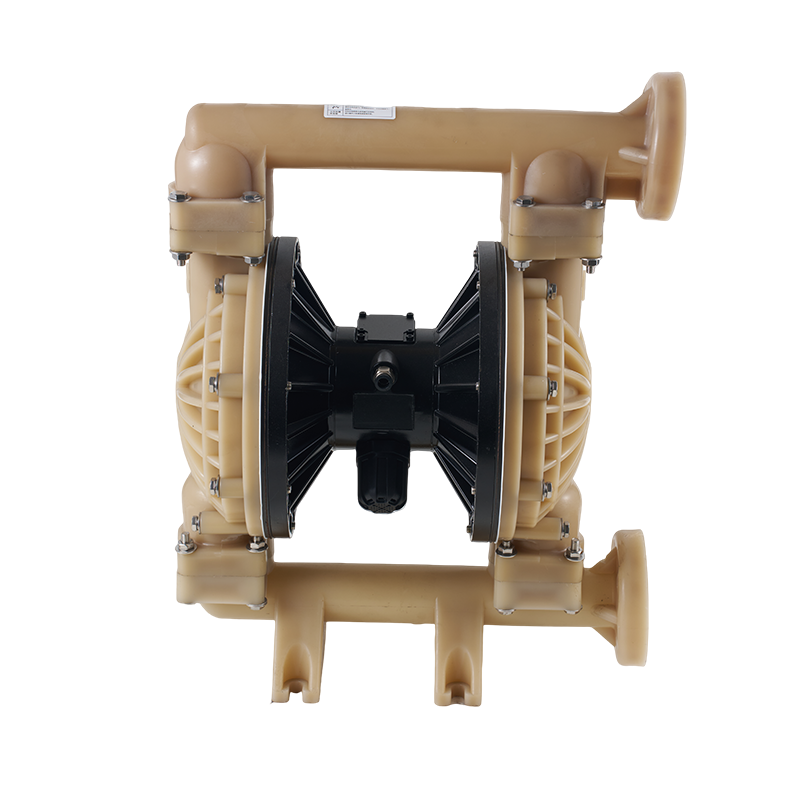

In the dynamic world of industrial fluid transfer and processing, selecting the right pump for specific applications is crucial. One of versatile and resilient options available today is the Rubber Diaphragm Pump with Teflon Liners. These pumps combine the flexibility and durability of rubber with the unparalleled corrosion resistance of Teflon, making them ideal for a wide range of demanding industrial processes.

A Rubber Diaphragm Pump operates on the principle of positive displacement, using a flexible rubber diaphragm to create a vacuum that draws fluid into the pump chamber and then expels it through the outlet. This design ensures a hermetic seal between the drive mechanism and the compression chamber, allowing the pump to transfer, compress, and evacuate the medium without the need for lubrication. The rubber diaphragm's elasticity allows it to withstand repeated flexing, making it suitable for continuous operation.

While rubber diaphragms are known for their flexibility and durability, they may not always be sufficient when dealing with highly corrosive or chemically aggressive fluids. This is where Teflon Liners come into play. Teflon, also known as PTFE (Polytetrafluoroethylene), is renowned for its exceptional chemical resistance, non-stick properties, and low friction coefficient. By incorporating Teflon liners into the rubber diaphragm, the pump gains the ability to handle a broader range of fluids, including those that would otherwise degrade or damage a standard rubber diaphragm.

The combination of Rubber Diaphragm Pumps with Teflon Liners makes them suitable for various industries, including chemical processing, pharmaceuticals, water treatment, and food processing. Here are some key scenarios where these pumps excel:

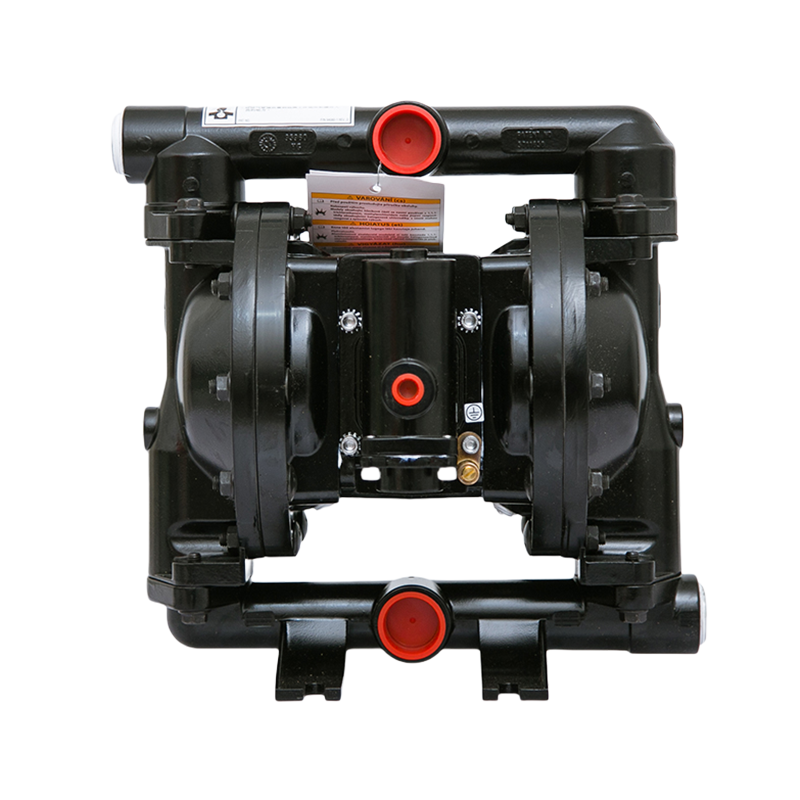

Chemical Processing: When dealing with strong acids, alkalis, or solvents, the corrosion resistance of Teflon ensures that the pump remains intact and functional over extended periods. This is particularly important in industries like petrochemicals, where the fluids being transferred can be highly corrosive.

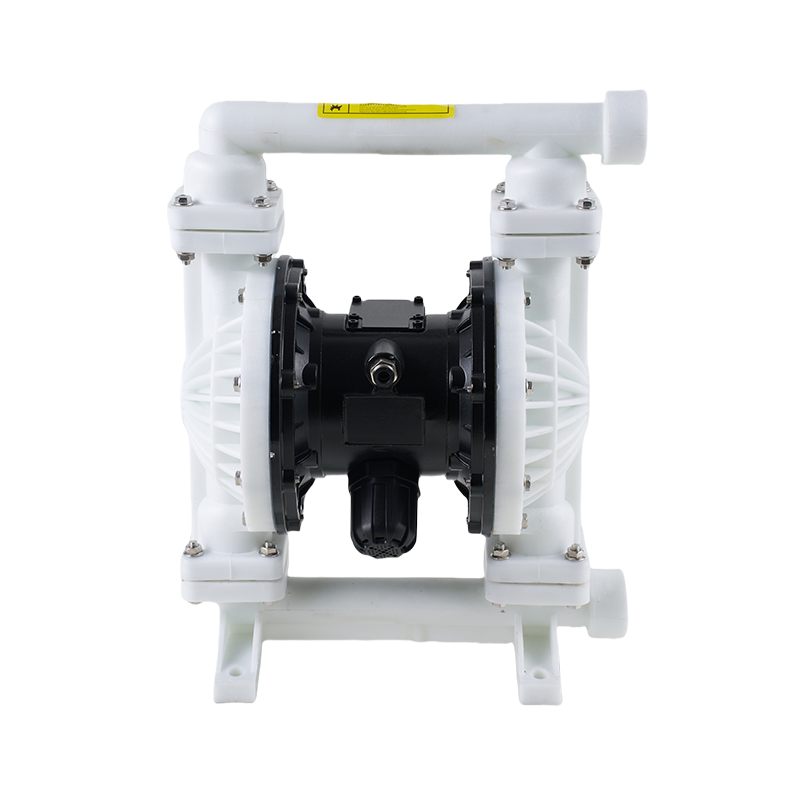

Pharmaceuticals and Food Processing: In these industries, maintaining the purity and integrity of the fluid is paramount. The non-stick properties of Teflon prevent any residue from adhering to the diaphragm, ensuring that the fluid remains uncontaminated. Additionally, the pump's ability to operate without lubrication eliminates the risk of contamination from lubricants.

Water Treatment: In water treatment plants, the pump may need to handle a variety of fluids, from raw water to treated effluent. The Teflon liner's resistance to hydrolysis and its ability to withstand a wide range of pH levels make it an ideal choice.

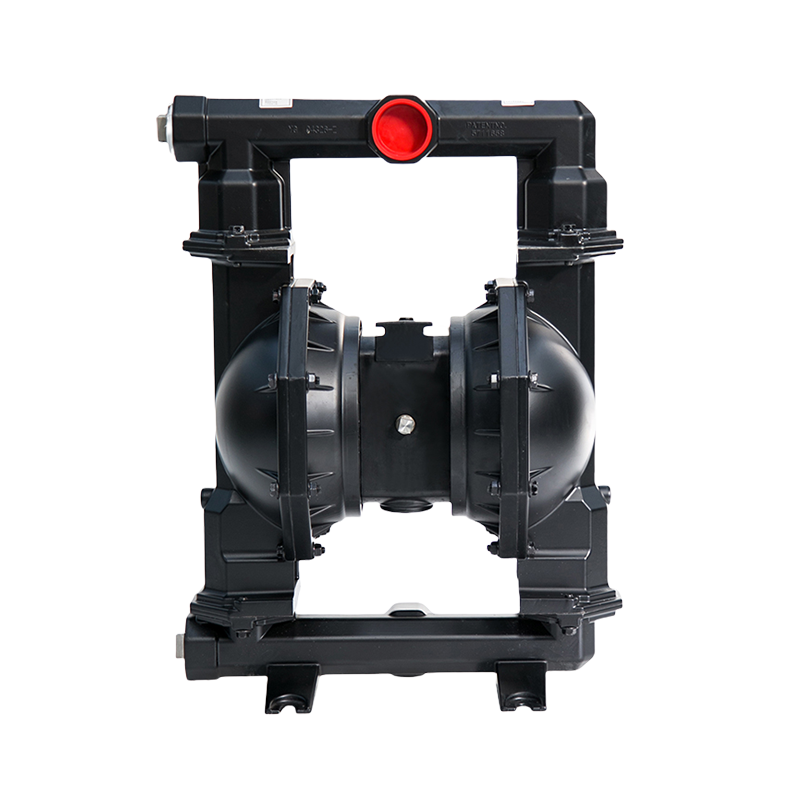

High-Pressure Applications: Teflon-lined rubber diaphragms offer enhanced flex resistance and durability, allowing them to withstand high pressures without tearing or degrading. This makes them suitable for high-pressure applications, such as in hydraulic systems or when transferring viscous fluids.

For even greater efficiency and reliability, some applications may benefit from Triple Diaphragm Pumps. These pumps feature three diaphragms working in tandem, providing a more consistent flow and reducing the risk of downtime due to diaphragm failure. The use of Teflon liners in triple diaphragm pumps further enhances their corrosion resistance and longevity, making them ideal for the demanding industrial processes.

When selecting a pump for applications involving corrosive or chemically aggressive fluids, Rubber Diaphragm Pumps with Teflon Liners offer a reliable and efficient solution. Their combination of flexibility, durability, and corrosion resistance makes them suitable for a wide range of industries and processes. Whether you are dealing with strong acids in chemical processing, maintaining purity in pharmaceuticals, or ensuring efficient water treatment, these pumps provide the performance and reliability needed to meet your industrial demands.

English

English русский

русский Español

Español عربى

عربى